Spring type split block structure positioning clamp of free curve surface work pieces

A curved surface workpiece and structure positioning technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve problems affecting work efficiency, increase the cost of free-form surface workpiece processing or measurement, increase the cycle of processing or measurement, and achieve versatility Good, high positioning accuracy, easy to use and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

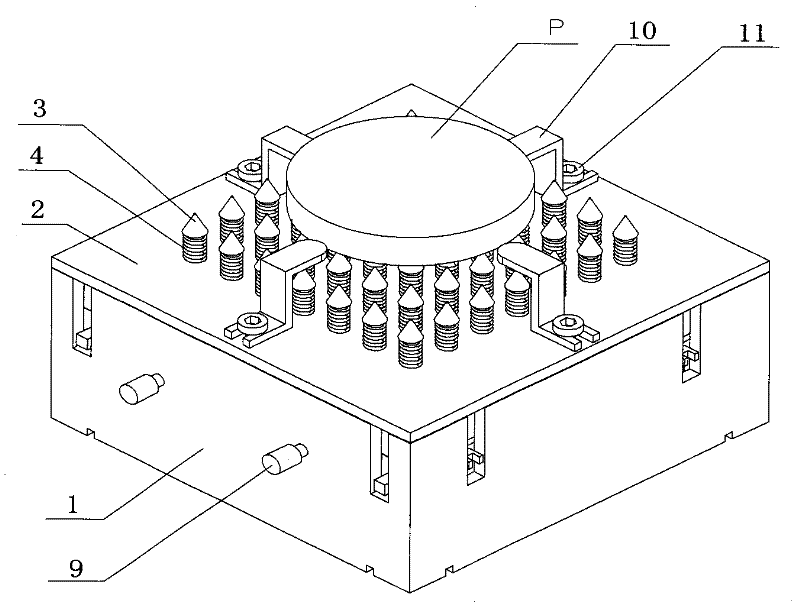

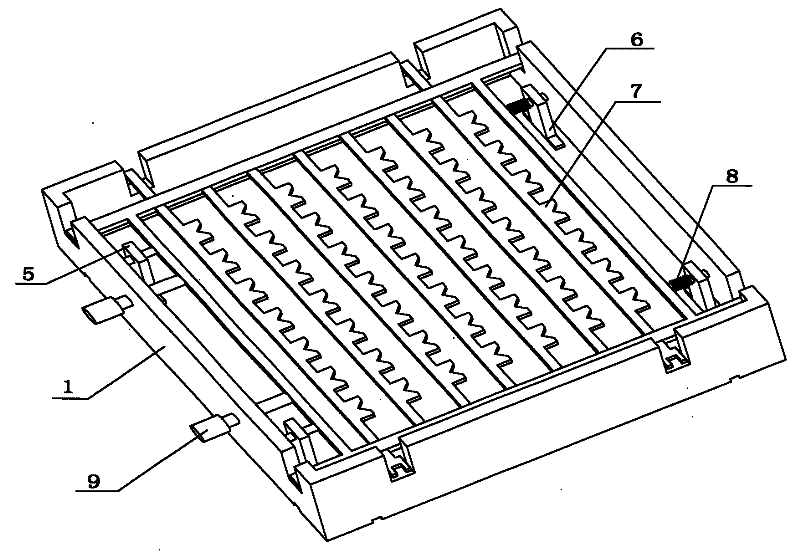

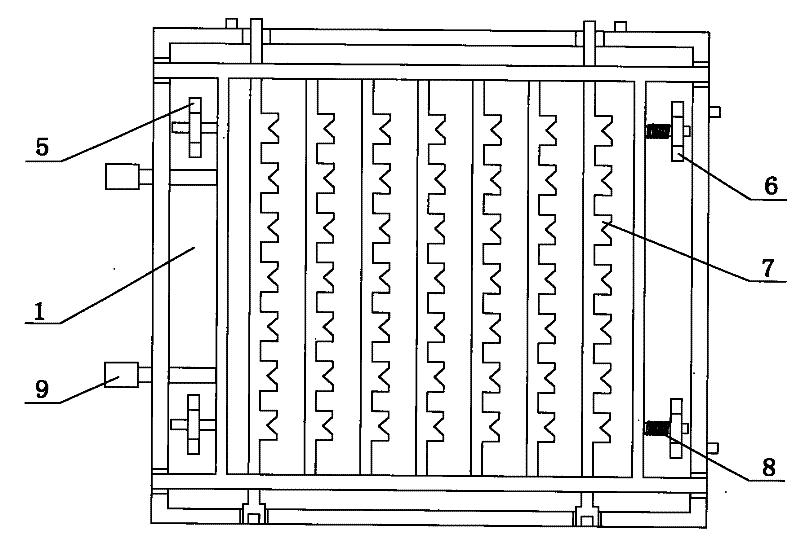

[0021] see Figure 1~3 , the embodiment of the present invention is provided with a base 1, an upper cover plate 2, a thimble 3, a load spring 4, a left bracket 5, a right bracket 6, a thimble clamping frame 7, a return spring 8, a locking screw 9, a fixed top block 10 and screw11. Among them, the upper cover plate 2 is installed on the base 1; the thimble 3 is installed on the upper cover plate 2 through the load spring 4; the left bracket 5 and the right bracket 6 are fixed on the base 1; the thimble clamping frame 7 is installed on the left bracket 5. In the right bracket 6; the locking screw 9 is installed on the base 1, when the locking screw 9 is tightened, the thimble clamping frame 7 can be pushed to move to the right, and the return spring 8 is compressed; the return spring 8 is installed on the thimble clamping frame 7 and the right bracket 6, when the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com