Hot-melt adhesive micro-tissue homogenizer

A tissue homogenization and hot melt adhesive technology, which is applied in the preparation of test samples, grain processing, etc., can solve the problems of long crushing time, temperature rise, damage, etc., and achieves low production price, high detection amount, and small sample loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

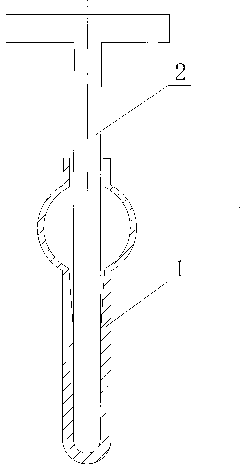

[0018] Specific implementation mode one: as Figure 1~3 As shown, the hot melt adhesive micro tissue homogenizer described in this embodiment is composed of a tube body 1 and a hammer body 2 inserted in the tube body 1, the tube body 1 is made of hot melt adhesive material, and the The hammer body 2 is a stainless steel hammer body.

[0019] The hot melt adhesive in this embodiment is a semi-elastic hot melt adhesive. The surface of the hammer body 2 and the internal surface of the pipe body 1 should be as smooth as possible, and the specification of the homogenizer can be scaled according to the working inner diameter φ3 of the pipe body from 3.0 to 10.0 mm. When selecting the specifications of the homogenizer, choose according to the volume of the sample to be processed. The pipe body 1 made of hot melt adhesive material and the stainless steel hammer body 2 are used together to achieve the close contact between the outer surface of the hammer body 2 and the inner wall of ...

specific Embodiment approach 2

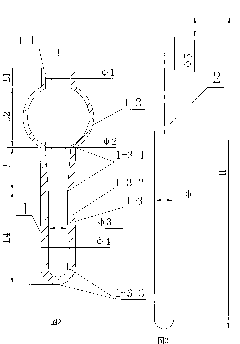

[0021] Specific implementation mode two: as figure 2 As shown, the tube body 1 in this embodiment is composed of three parts: a circular tube-shaped opening section 1-1, a spherical body section 1-2 and a tube main body section 1-3. The circular tube-shaped opening section 1-1, the spherical body The section 1-2 and the main section 1-3 of the pipe body are arranged in sequence from top to bottom and the three are connected. The shape bottom cover 1-3-3 is formed, and the upper circular tube 1-3-1, the middle circular tube 1-3-2 and the hemispherical bottom cover 1-3-3 are arranged in sequence from top to bottom and the three are connected, and the upper circle The inner cavity of the tube 1-3-1 is a truncated cone that gradually converges inward from top to bottom, the inner cavity of the middle circular tube 1-3-2 is cylindrical, and the inner cavity of the upper circular tube 1-3-1 is in the same shape as The inner cavity of the middle circular tube 1-3-2 has a smooth tra...

specific Embodiment approach 3

[0022] Specific implementation mode three: as Figure 1~3 As shown, the diameter φ of the working section of the hammer body 2 in this embodiment is equal to the working inner diameter φ3 of the intermediate tube 1-3-2. The inner diameter of the working part of the pipe body should be the same as the working part of the hammer or slightly smaller than the diameter of the hammer, which can make the homogenization effect better. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com