Stiffening finishing composition for silk and application in cutting, carving and decoration thereof

A technology of stiffening and composition, which is applied in textile decoration, textile and papermaking, fiber treatment, etc. It can solve problems such as stiffening is difficult to shape, cut-and-cut art is difficult to expand, and creation space is limited, and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1 After stiffening a certain silk fabric, it is made into Chinese zodiac cut and engraved silk paper

[0074] The stiff finishing composition that adopts comprises by the content percentage of its component:

[0075] Component Percentage

[0076] Stiffener ZB-602 90%

[0077] Silk antibacterial and antimildew finishing agent FM-2598 2%

[0078] Silk anti-aging finishing agent FZ-2599 3%

[0079] Penetrant JFC 2%

[0080] Deionized water 3%

[0081] Antibacterial and anti-mildew finishing agent FM-2598 for silk already has water-repellent additives; anti-aging finishing agent FZ-2599 for silk has anti-ultraviolet and anti-yellowing additives; all the materials used above are " It is a product produced according to the standard of Jiangsu Silk Science Research. The main component of the stiffener ZB-602 used is polyacrylate; the penetrant is the penetrant JFC, non-ionic.

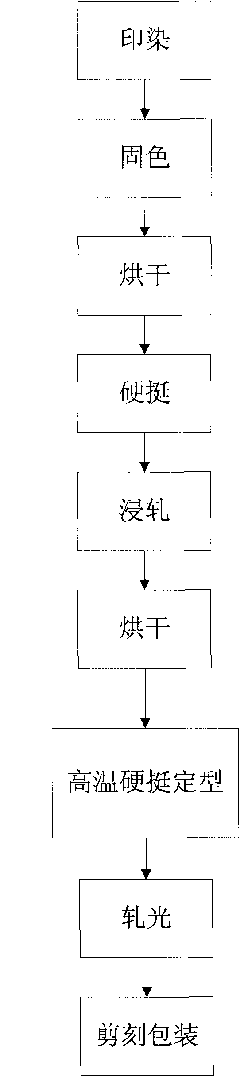

[0082] Stiff finishing process such as figure 1 As shown, it can be manually operate...

Embodiment 2

[0083] Example 2 After stiffening a certain silk fabric, it is made into Chinese zodiac cut and engraved silk paper

[0084] The stiff finishing composition that adopts comprises by the content percentage of its component:

[0085] Component Percentage

[0086] Stiffener ZB-602 88%

[0087] Silk antibacterial and antimildew finishing agent FM-2598 2.4%

[0088] Silk anti-aging finishing agent FZ-2599 3.2%

[0089] Penetrant JFC 2.3%

[0090] Deionized water 3.1%

[0091] Antibacterial and anti-mildew finishing agent FM-2598 for silk already has water-repellent additives; anti-aging finishing agent FZ-2599 for silk has anti-ultraviolet and anti-yellowing additives; all the materials used above are " It is a product produced according to the standard of Jiangsu Silk Science Research. The main component of the stiffener ZB-602 used is polyacrylate; the penetrant is the penetrant JFC, non-ionic.

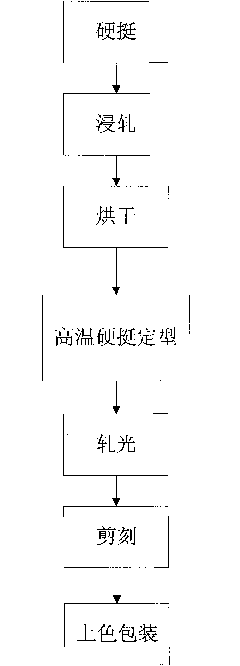

[0092] Stiff finishing process such as figure 2 As shown, it can be done by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com