Partial energy coupled separation system of carbon 3, carbon 4 and carbon 5 used in predepropanization technological process and operation method

A technology for depropane ethylene and separation systems, which is applied in fractionation, gas mixture processing, petroleum industry and other directions to achieve the effect of reducing quantity, equipment investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

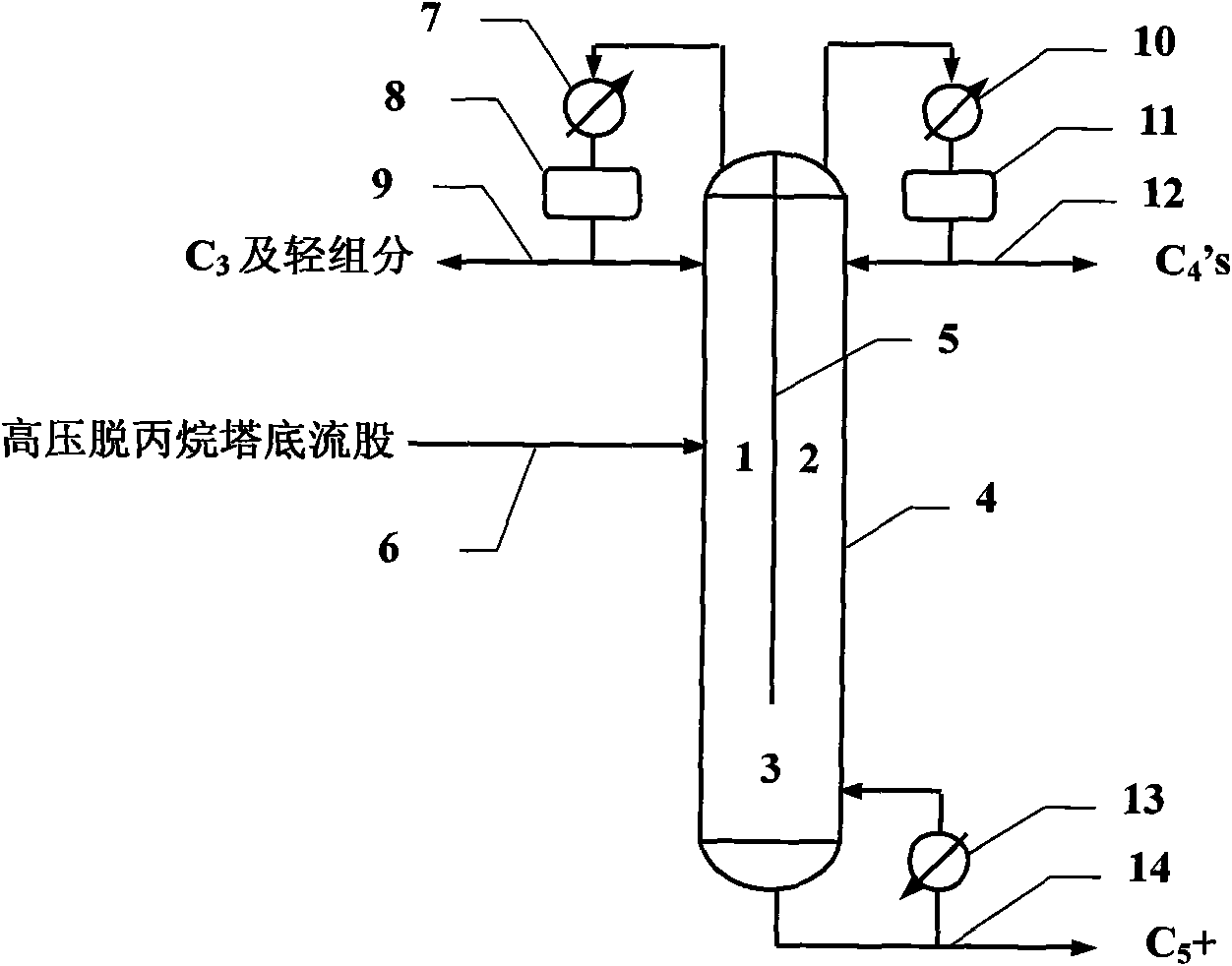

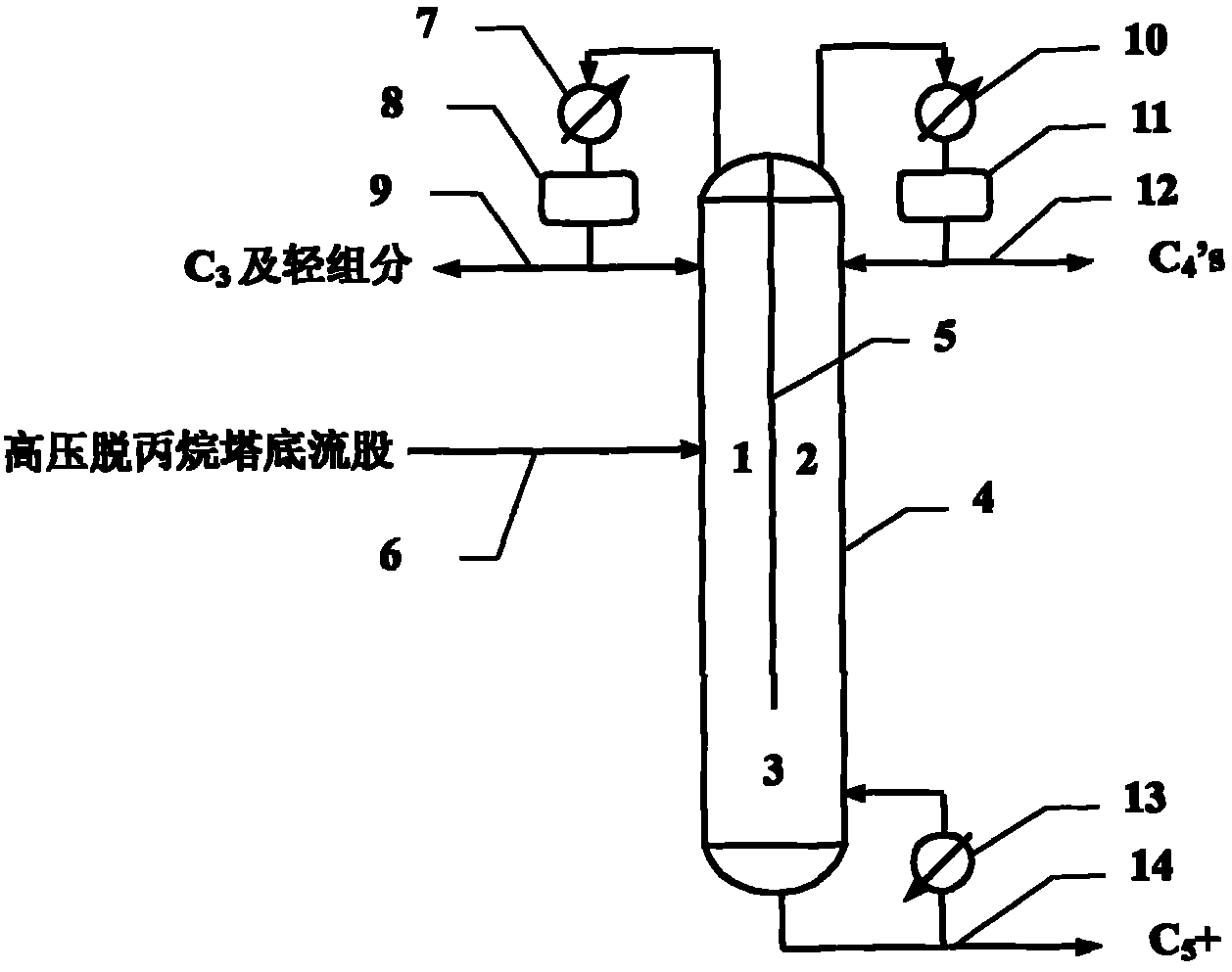

[0028] Embodiment 1: as figure 1 , the direct separation sequence structure part energy coupling partition column 4 is used for rectification and separation when the content of C3 in the raw material is relatively large, that is, the C in the raw material 3 The content is greater than that of C 4 and C 5+ Component content and raw material composition are shown in Table 1. The tower contains a vertical wall, that is, the partition 5 starts from the top of the tower to a certain tray in the tower, and divides the tower into three areas, area 1, area 2 and area 3. The raw material enters the feed plate from area 1 through the feed line 6, and area 1 mainly realizes C 3 and C 4 、C 5+ Separation between components, C 3 The fraction is extracted from the top of the zone 1 tower and enters the reflux tank 8 through the condenser 7, and a part is used as C 3 The product is withdrawn from pipeline 9, and another part is returned to zone 1 as reflux liquid. Separation by zone 1...

Embodiment 2

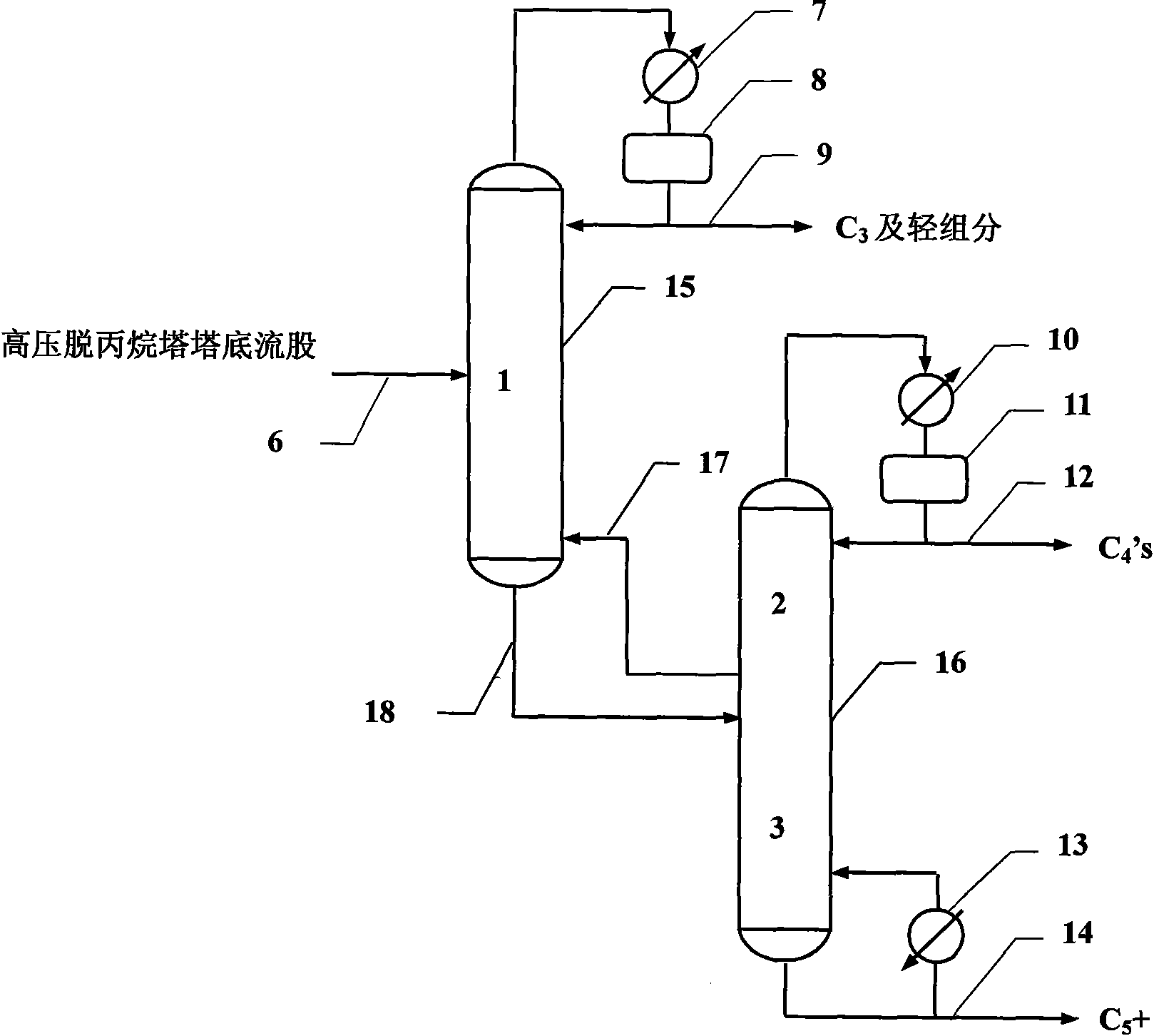

[0052] Embodiment 2: as figure 2 , a partially energy-coupled direct distillation column sequence, used for distillation and separation when the C3 content in the raw material is relatively high. The composition of the raw material is shown in Table 1. It includes two rectification towers, the first rectification tower 15 of the direct sequence and the second rectification tower 16 of the direct sequence. The separation process composed of these two columns is thermodynamically the same as figure 1 The direct separation sequence structure part energy coupling rectification tower 4 in the direct separation sequence is equivalent, and the region 1 corresponding to the tower 15 mainly realizes C 3 and C 4 、C 5+ The separation between the components, the zone 2 formed by the rectification section of the column 16 mainly realizes C 4 The rectification and separation of components, the zone 3 formed by the stripping section of tower 16 realizes C 5+ Stripping separation of com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com