Method for preparing antibacterial agent achieving antibacterial effect on decorative textile fabric

A technology of antibacterial agent and antibacterial finishing agent, which is applied in the field of textile decorative fabric manufacturing, can solve the problems of inability to achieve antibacterial and inapplicability, and achieve the effects of improving antibacterial washability, strong adhesion and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

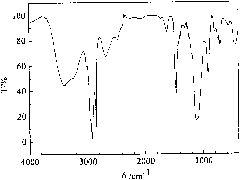

[0017] Embodiment 1: A kind of preparation method that is used for the antibacterial agent of textile decorative fabric, in the 100mL four-necked flask that thermometer, reflux condenser and stirrer are housed, after the silane of 1: 1.5~3, tertiary amine are mixed, add 0.15%~3% catalyst sodium iodide and 1.2%~2.5% antioxidant, add organic solvent at the same time, pass nitrogen protection, control the system at 65~80°C, stir and react, after the reaction is completed, cool and discharge to obtain a light yellow liquid Antibacterial finishing agent, its reaction equation is as follows:

[0018]

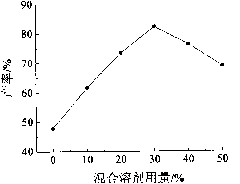

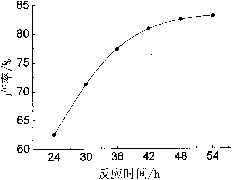

[0019] The organic solvent is mixed with methanol and dimethyl sulfoxide in a ratio of 4-2.5:1, the dosage is 30-40%, the reaction temperature is 65-80°C, and the reaction yield can reach more than 80% after 48 hours of reaction.

Embodiment 2

[0020] Example 2: On the basis of Example 1, after mixing 1:1.5 silane and tertiary amine, 0.15% catalyst sodium iodide and 1.2% antioxidant were added.

Embodiment 3

[0021] Example 3: On the basis of Example 1, after mixing 1:3 silane and tertiary amine, 3% catalyst sodium iodide and 2.5% antioxidant were added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com