Bearing structure, and its manufacturing method

一种轴承、滚动轴承的技术,应用在轴承结构领域,能够解决制造成本增加、加工复杂等问题,达到制造成本降低、降低制造成本、抑制位置偏移的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

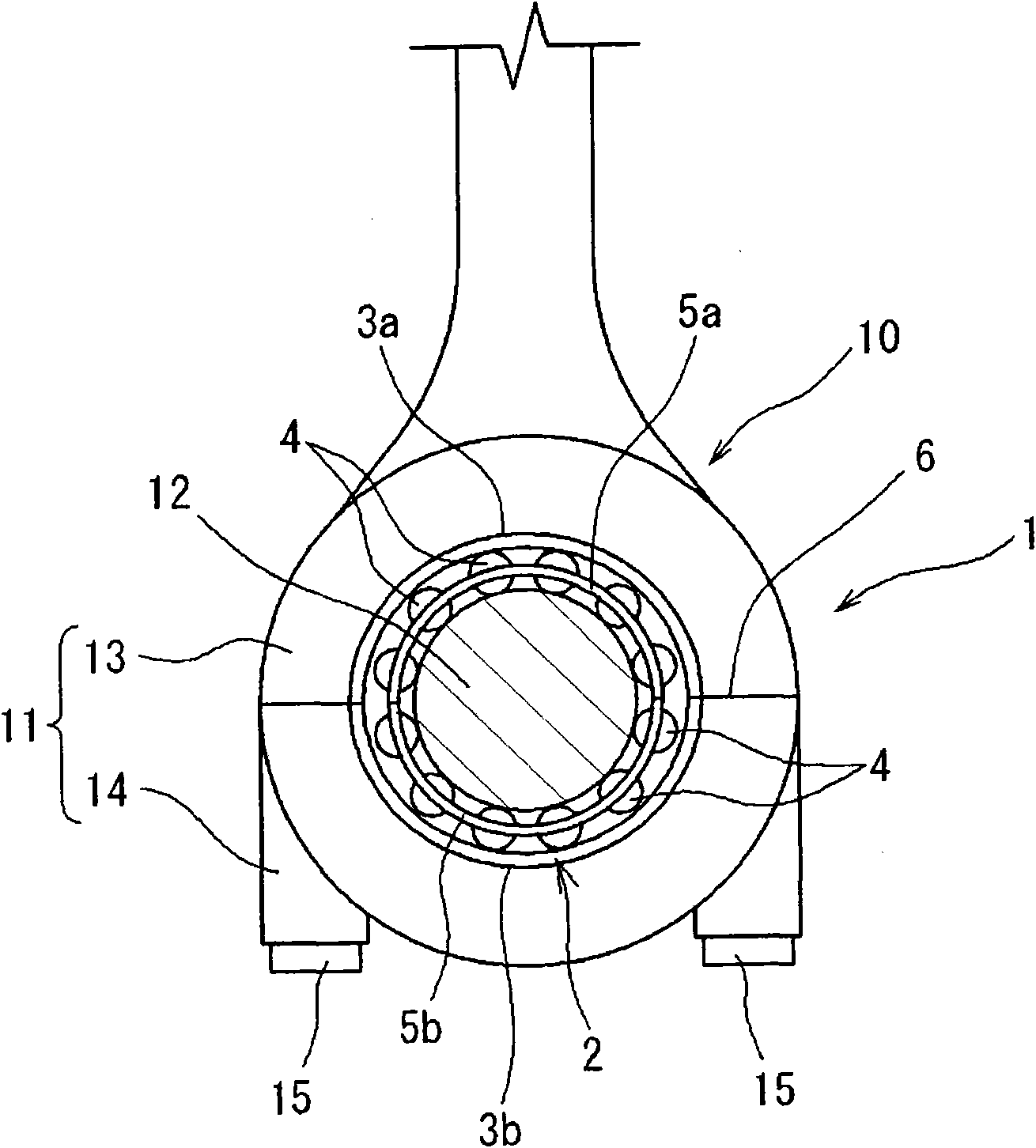

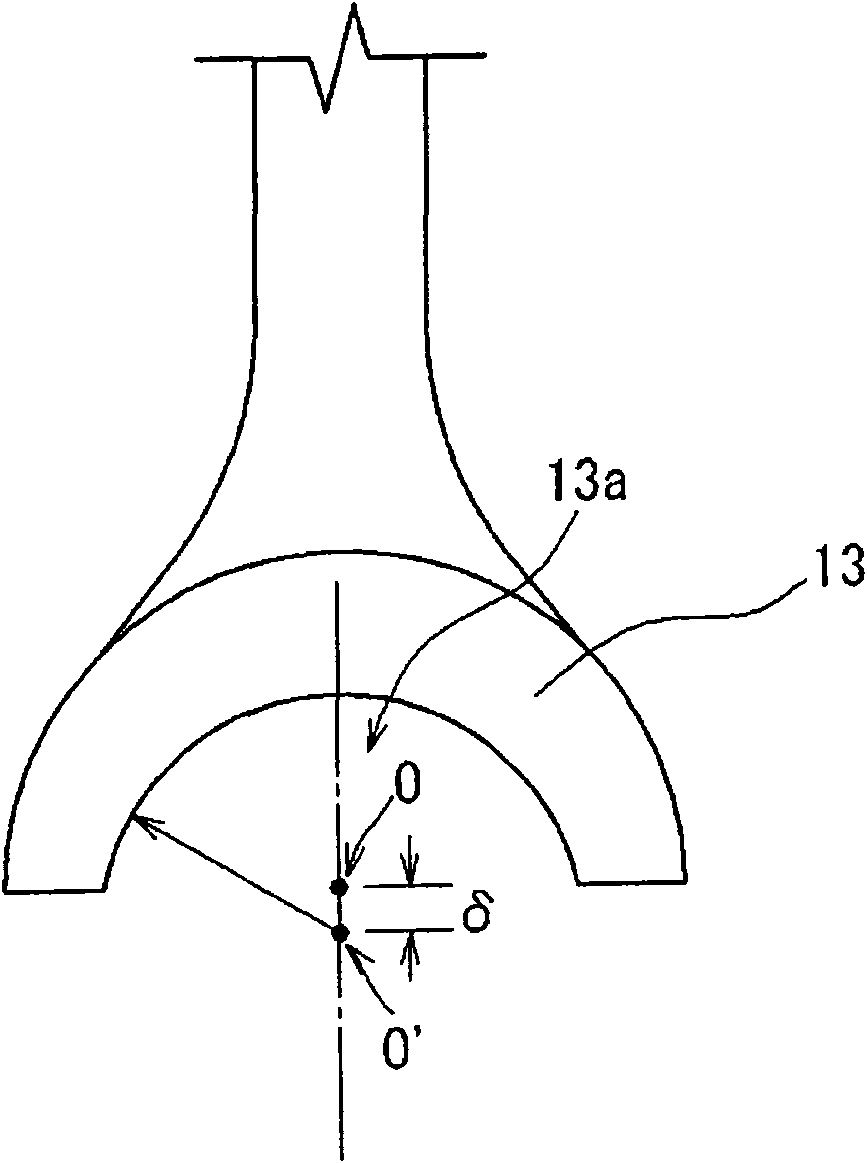

[0081] figure 1 It is a cross-sectional explanatory view of the large end of the connecting rod to which the bearing structure 1 of the first embodiment of the present invention is applied. The large end 11 of the connecting rod 10 is supported by the crankshaft 12, and a piston (not shown) is attached to a small end (not shown) via a pin.

[0082] The above-mentioned large end portion 11 is formed by connecting and fixing the second housing portion, which is the cover portion 14, which has a substantially semicircular cross-section, to the main body portion 13, which has a substantially semicircular cross-section, with bolts 15 The support hole 16 has a substantially circular cross-section. The split type rolling bearing 2 is inserted into the support hole 16 formed by the main body portion 13 and the cover portion 14 with a substantially circular cross section.

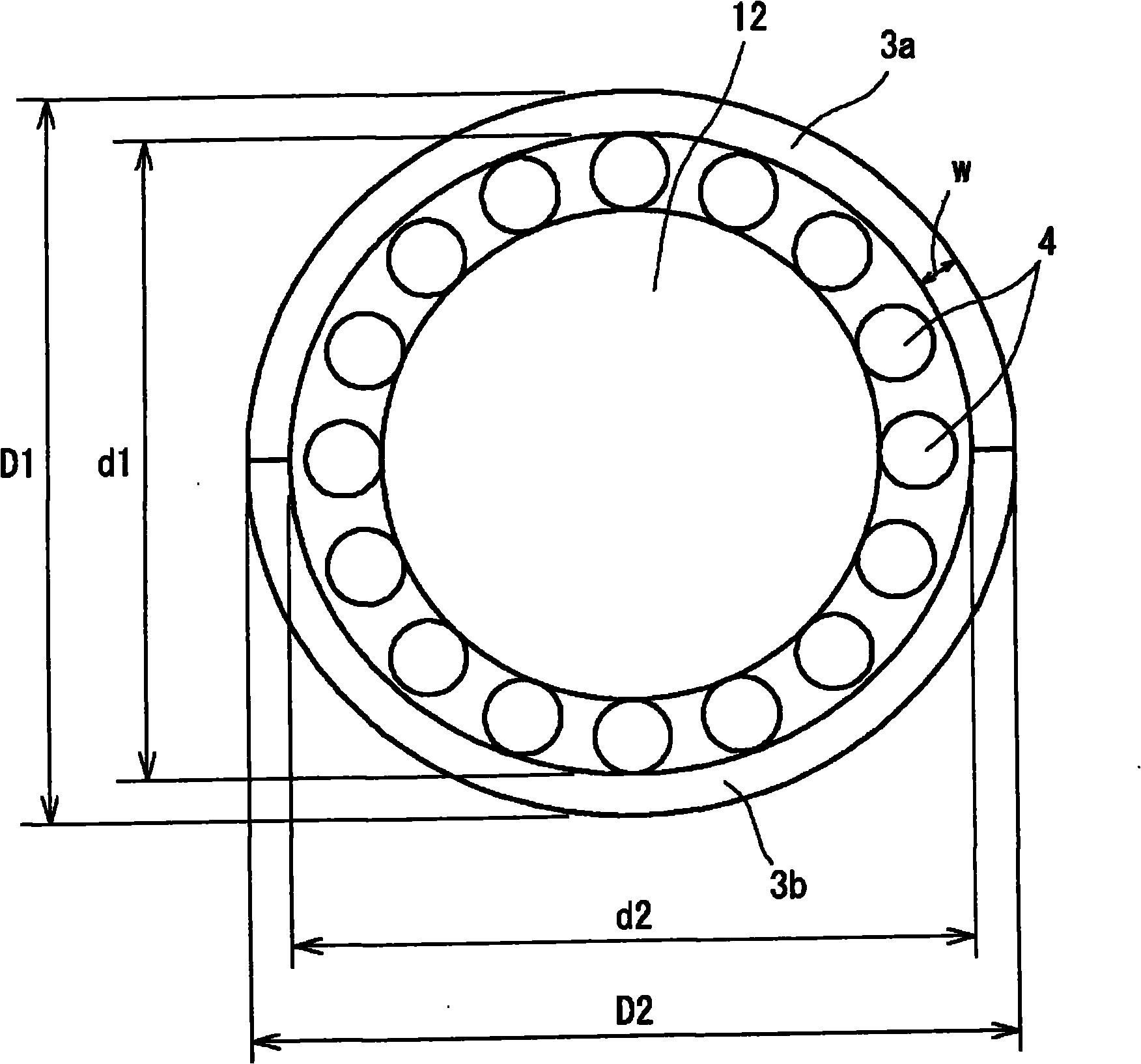

[0083] The rolling bearing 2 includes two sets of split outer rings 3a, 3b arranged in close contact in the support ...

no. 2 approach

[0092] Figure 5 It is a cross-sectional explanatory view of the large end 111 of the connecting rod 110 using the bearing structure 101 of the second embodiment of the present invention. The connecting rod 110 has a structure in which a split-type rolling bearing 102 is inserted into a support hole 116 of a large end 111 which is a shell formed by a first shell piece 113 and a second shell piece 114, and a crankshaft 112 is further embedded. In this specification, the bearing structure 101 is called by the shell ( Figure 5 Among them, the first housing part 113, the second housing part 114), and the split type rolling bearing 102 constitute a structure.

[0093] The split rolling bearing 102 consists of split outer rings 103a, 103b, a plurality of rolling elements 104, 104 arranged to be rollable on the inner surfaces of the split outer rings 103a, 103b, and a plurality of the rolling elements 104, 104 is constituted by split type holders 105a and 105b that are held at predeter...

no. 3 approach

[0107] Picture 9 It is a cross-sectional explanatory view of the large end of the connecting rod to which the bearing structure 201 of the third embodiment of the present invention is applied. The large end portion 211 of the connecting rod 210 is supported by the crankshaft 212, and a piston (not shown) is attached to the small end portion (not shown) via a pin.

[0108] The above-mentioned large end portion 211 is formed by connecting and fixing the cover portion 214, which is a second housing having a concave portion with a substantially semicircular cross-section, to the main body portion 213 having a concave portion having a substantially semicircular cross-section with a bolt 215 to form a substantially circular cross section The structure of the support hole 216. The split type rolling bearing 202 is inserted into the support hole 216 formed by the main body portion 213 and the cover portion 214 with a substantially circular cross section.

[0109] The rolling bearing 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com