Nucleator masterbatch for polyolefin resin

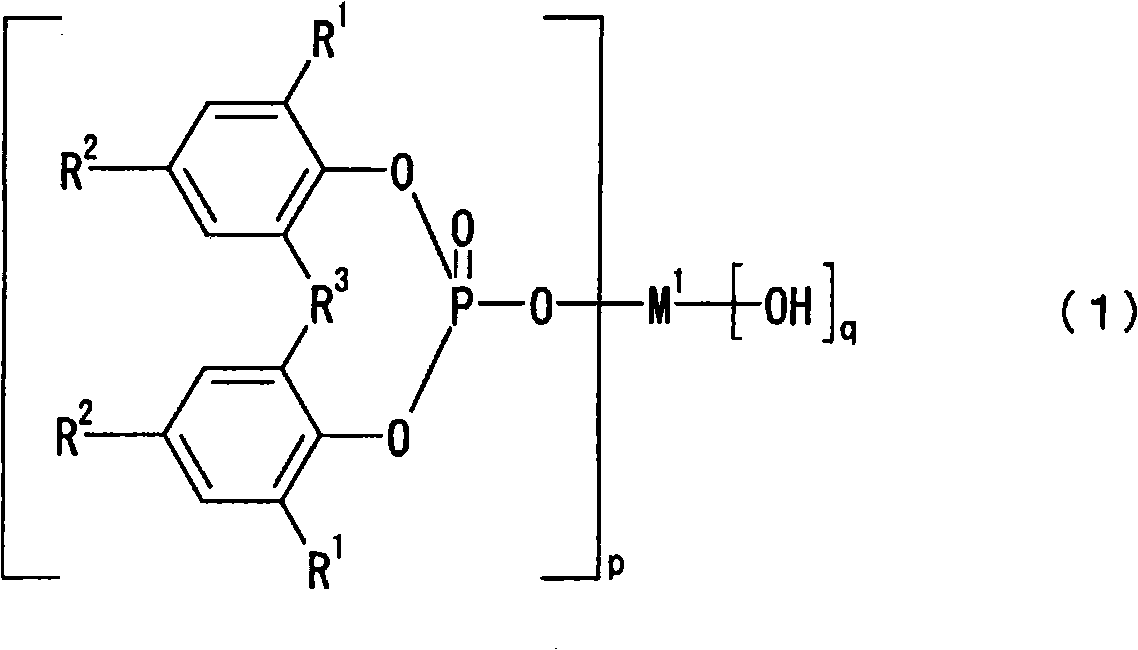

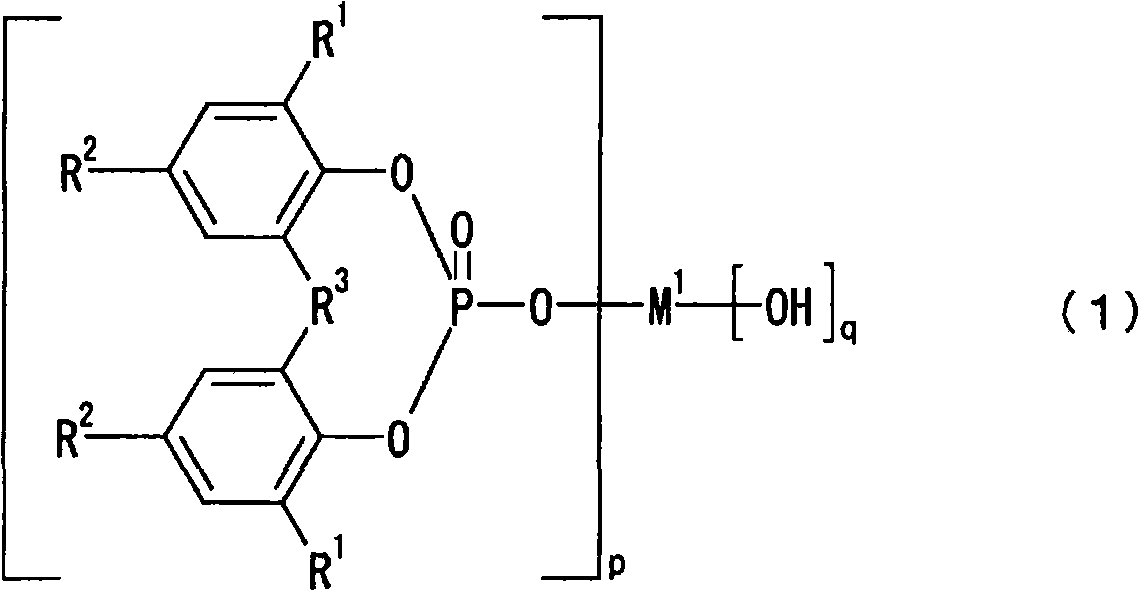

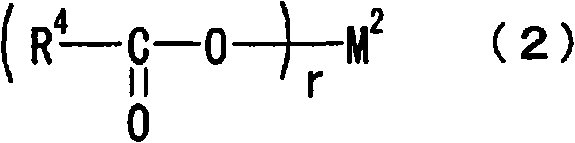

一种聚烯烃树脂、成核剂母料的技术,应用在聚烯烃树脂组合物领域,能够解决不能表现出添加效果、分散性不充分、相容性不充分等问题,达到提高透明性和机械物性、相容性优异、耐热着色性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0113] Add 100 parts by mass of homopolypropylene resin (melt index 8-9), 0.1 part by mass of phenolic antioxidant tetrakis[methylene-3-(3',5'-di-tert-butyl-4'-hydroxyphenyl ) propionate] methane, 0.1 mass part of phosphorus antioxidant tris (2,4-di-tert-butylphenyl) phosphite, 0.05 mass part of calcium stearate, and the aromatic phosphate metal salt compound composition (Component (B)) was added in an amount of 0.1 parts by mass to the masterbatch (MB-1) prepared in advance according to the formulation shown in the above Table 1, mixed with a Henschel mixer at 1100 rpm for 5 minutes, and then heated at 250°C and 160 rpm Extrusion processing under certain conditions to produce pellets. The pellets were injection molded at 230° C. to obtain a test piece having a thickness of 1 mm, and the haze value (JIS K7105) and flexural modulus (ASTMD-790) of the test piece were evaluated. The results are shown in Table 4 below.

Embodiment 2-1~2-3 and comparative example 2-1~2-5

[0117] Add 100 parts by mass of homopolypropylene resin (melt index 8 to 10), 0.1 part by mass of phenolic antioxidant tetrakis[methylene-3-(3',5'-di-tert-butyl-4'-hydroxyphenyl ) propionate] methane, 0.1 mass part of phosphorus antioxidant tris (2,4-di-tert-butylphenyl) phosphite, 0.05 mass part of calcium stearate, and the aromatic phosphate metal salt compound composition ((B) Component) was added in an amount of 0.2 parts by mass to the masterbatch types shown in the following Table 5, mixed with a Henschel mixer at 1100rpm for 5 minutes, and extruded at 250°C and 160rpm. Make pellets. The pellets were injection molded at 230° C. to obtain a test piece having a thickness of 1 mm, and the haze value, flexural modulus and Y.I. of the test piece were evaluated (yellowness index: measured by a color difference meter manufactured by Suga Test Instruments Co., Ltd.) . The results are collectively shown in Table 5 below.

Embodiment 3-1~3-2 and comparative example 3-1

[0119] Add 100 parts by mass of homopolypropylene resin (melt index 7-8), 0.1 part by mass of phenolic antioxidant tetrakis[methylene-3-(3',5'-di-tert-butyl-4'-hydroxyphenyl ) propionate] methane, 0.1 mass part of phosphorus antioxidant tris (2,4-di-tert-butylphenyl) phosphite, 0.05 mass part of calcium stearate, and the aromatic phosphate metal salt compound composition ((B) Component) was added in an amount of 0.2 parts by mass to the masterbatch types shown in the following Table 6, mixed with a Henschel mixer at 1100 rpm for 5 minutes, and extruded at 250°C and 160 rpm to produce particles. A test piece having a thickness of 1 mm was obtained by injection molding at 230° C. using the pellets, and the haze value and flexural modulus of the test piece were evaluated. The results are collectively shown in Table 6 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com