Method for processing faulty wire of x-ray flat panel detector image and device thereof

A flat-panel detector and bad wire technology, applied in image communication, electromagnetic wave detection, color TV components, etc., can solve the problems of second-level processing time, long processing time, loss of image details, etc., to facilitate upgrade operations , The effect of low upgrade cost and reduced detail loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

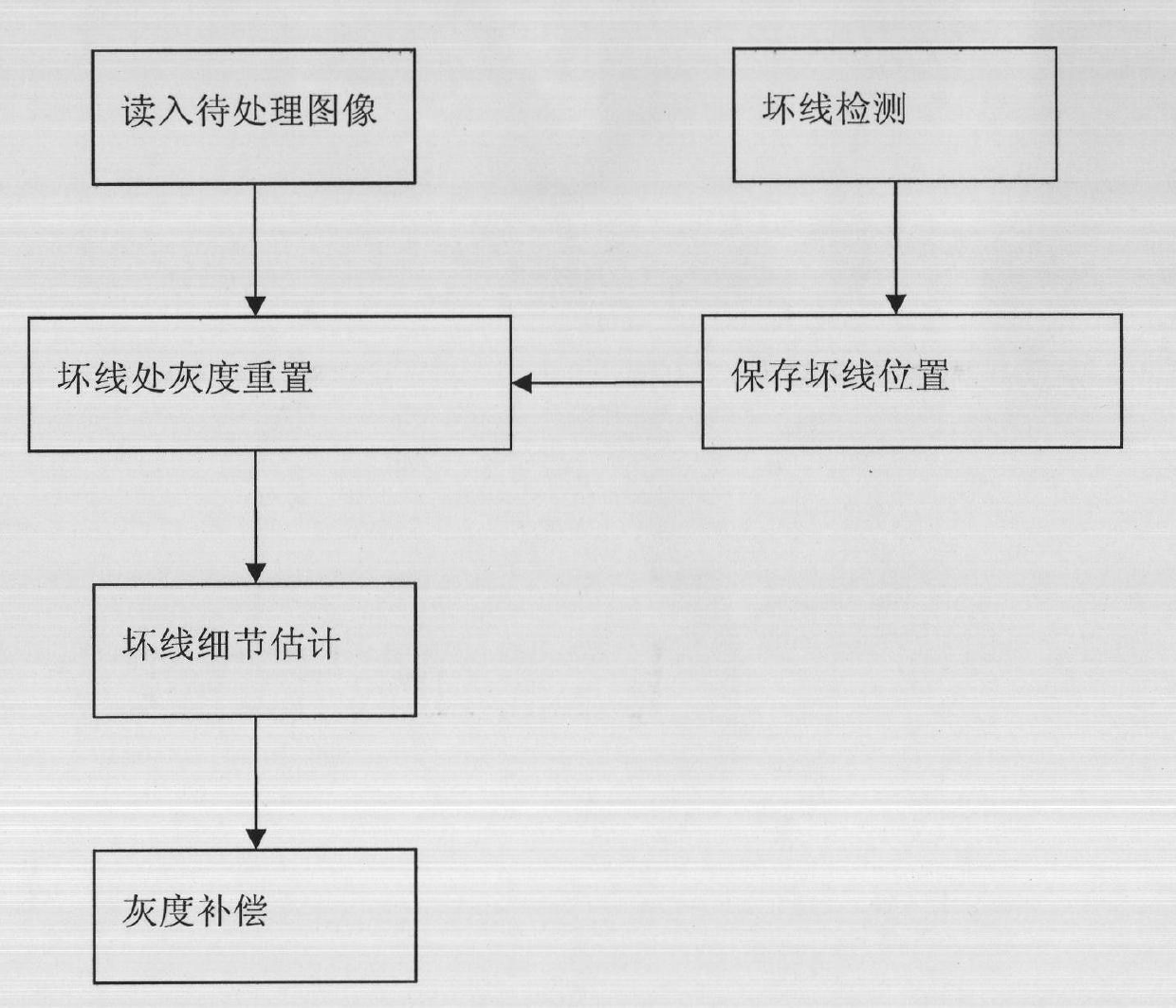

[0018] The specific implementation of the method and device of the present invention will be described in detail below in conjunction with the accompanying drawings. For the shortcoming of prior art method, the present invention provides the method for processing bad line of X-ray flat panel detector image, and it comprises the following steps:

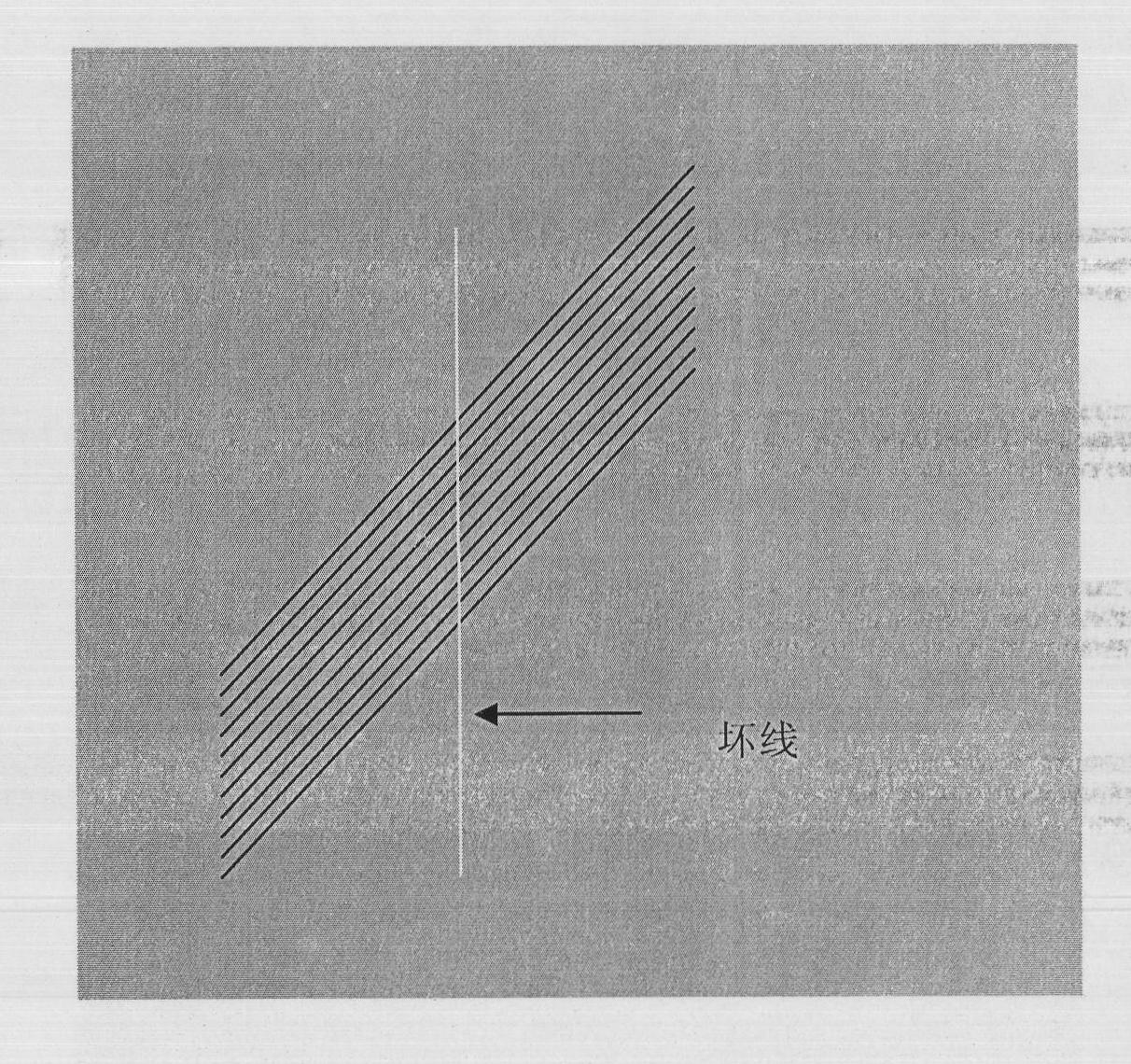

[0019] Detect the position of the bad line in the X-ray flat panel detector image;

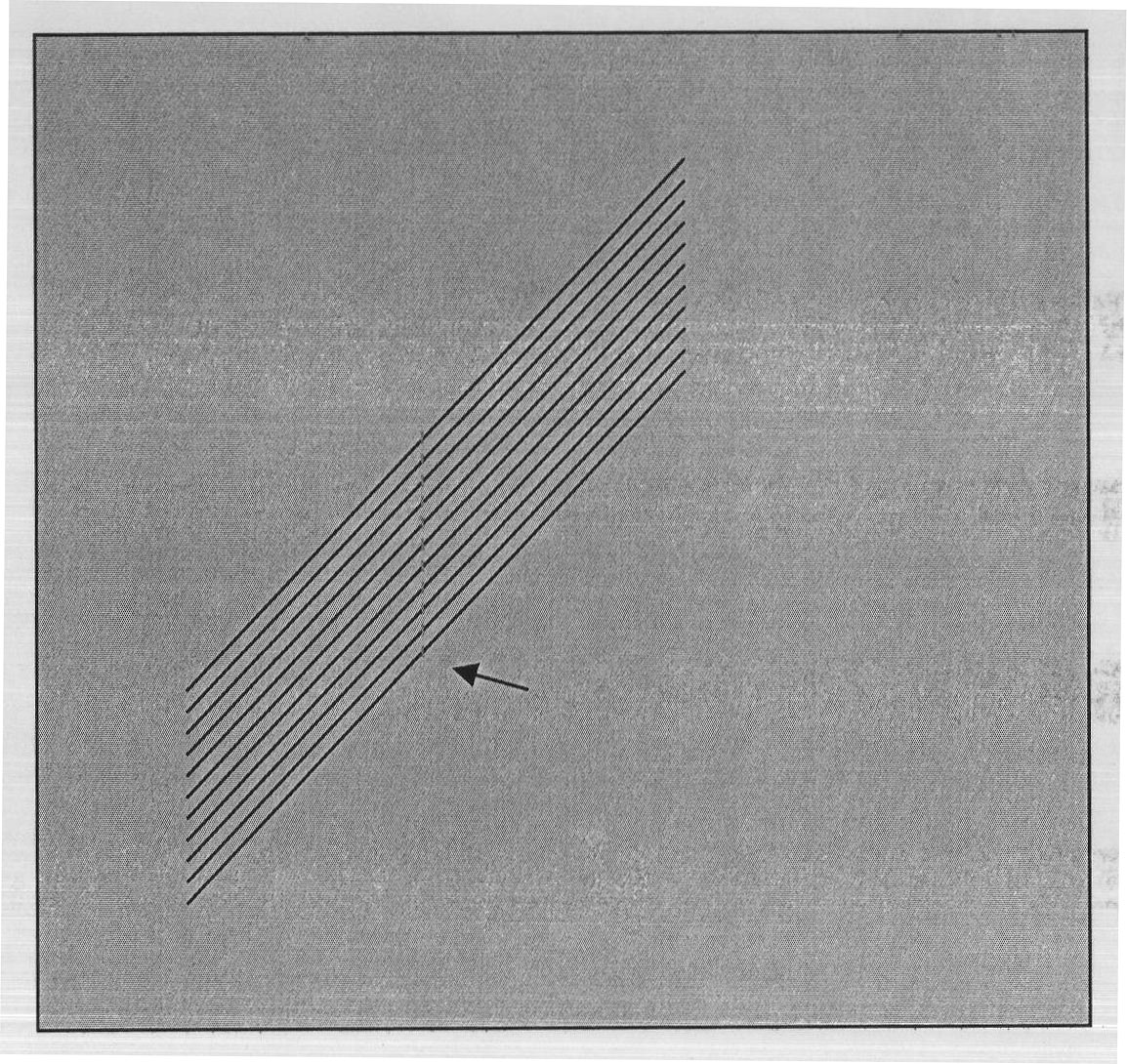

[0020] In the X-ray flat panel detector image to be processed, use the image data in the image sub-region containing the bad line to estimate the detail information of the image pixels at the bad line, and obtain an image after detail estimation;

[0021] In the image after the detail estimation, the image data of the non-bad line image pixels in the neighborhood of the bad line is used to calculate the compensation amount, and the image data of the image pixels at the bad line are compensated.

[0022] The present invention detects and stores the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com