Novel valve module of converter valve for high-voltage direct-current power transmission based on thyristor

A high-voltage direct current transmission and valve module technology, which is applied in the direction of output power conversion devices, circuits, electrical components, etc., to achieve the effects of shortening the distance of electrical wiring, reducing costs, and optimizing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

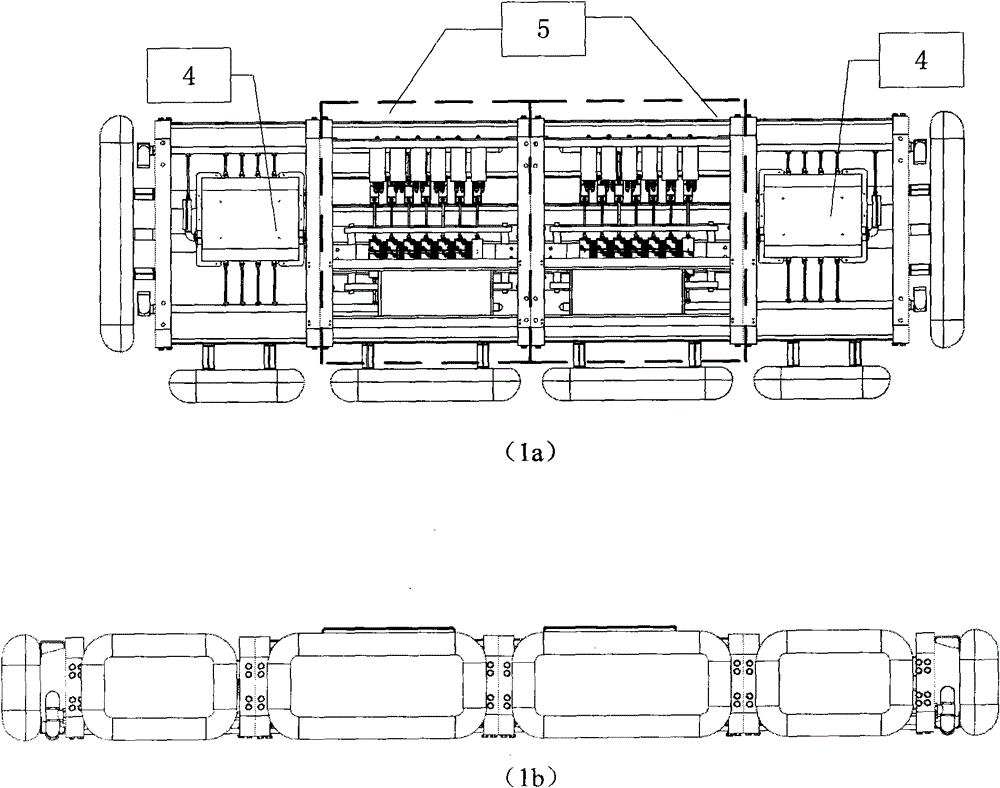

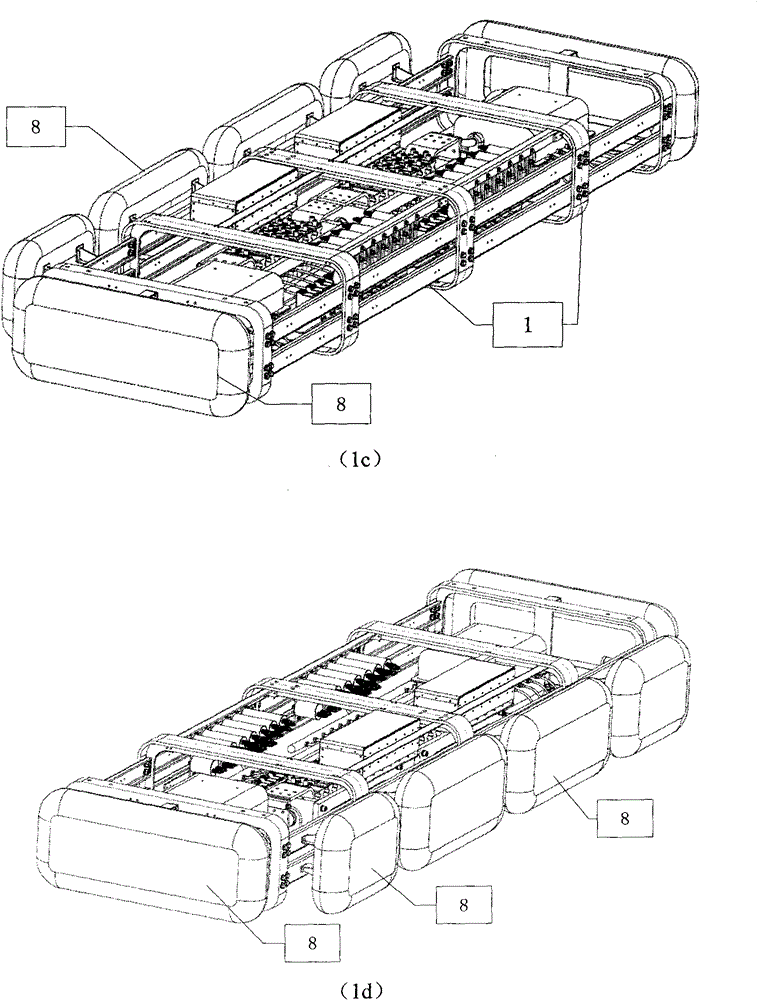

[0039] like figure 1 and figure 2 As shown, the valve module consists of five aluminum alloy ring frames 12 and four insulating groove beams 11 to form the valve module manufacturing frame 1, and the insulating groove beams 11 are located on both sides of the valve module frame. Inside the supporting frame of the valve module, various components of the valve module are arranged, wherein the saturable reactor 4 is located on both sides of the valve module in the length direction, and the thyristor-level assembly 5 is located in the middle of the valve module. There are multiple shielding covers on the periphery of the valve module, and there is no shielding cover on the side of the damping capacitor, and the structure of the shielding cover is a special rounded corner design. The electrical connection between the saturable reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com