Waveguide grating coupler with distributed Bragg reflector and manufacturing method thereof

A technology of Bragg reflector and waveguide grating, which is applied in the coupling of optical waveguide and other directions, can solve the problems of complex process and low coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

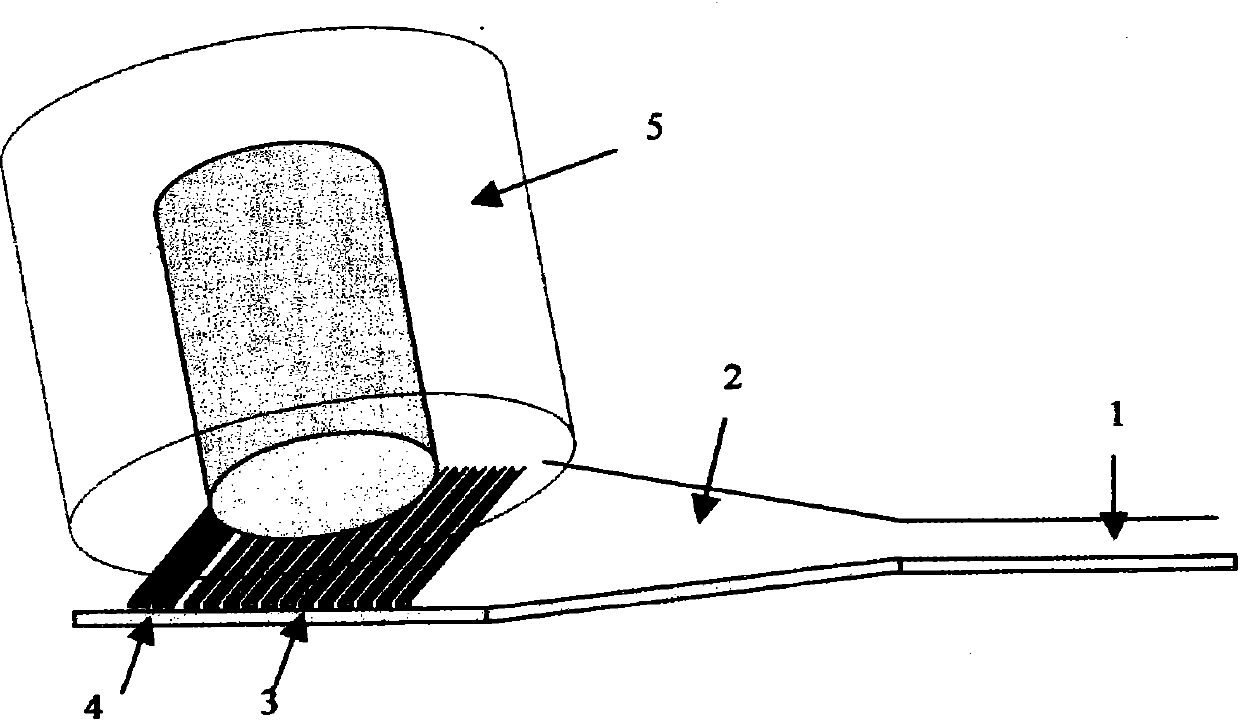

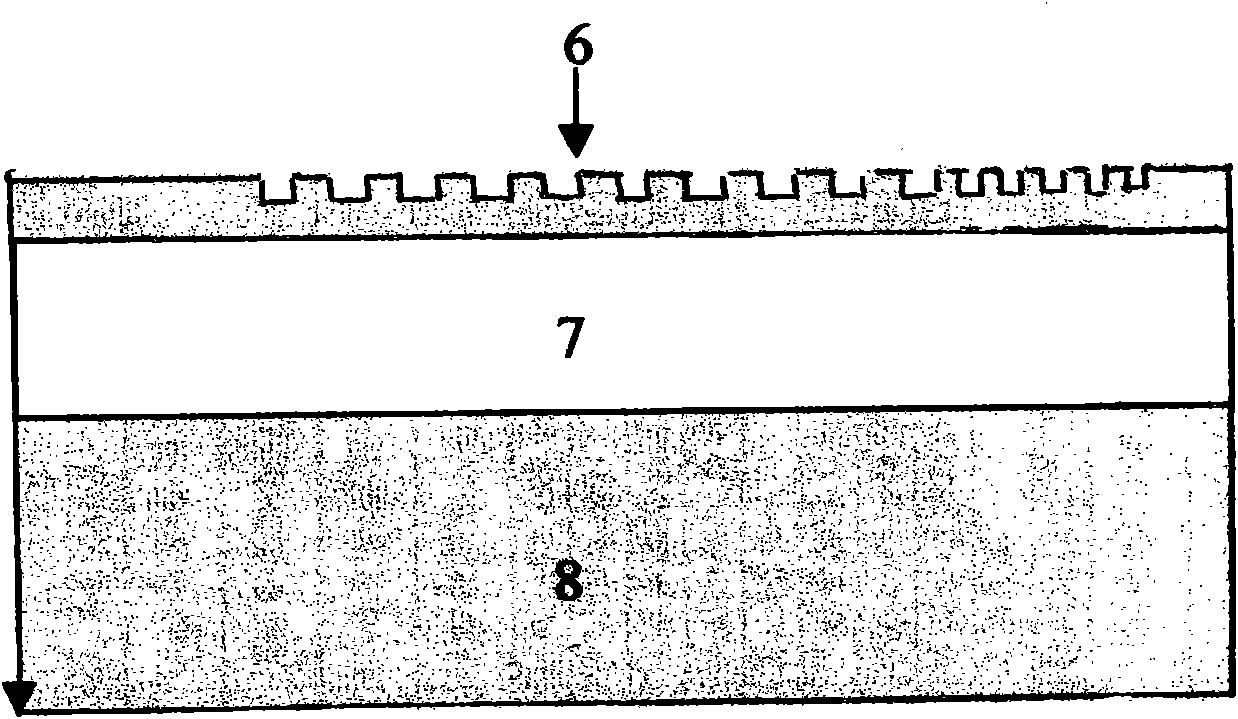

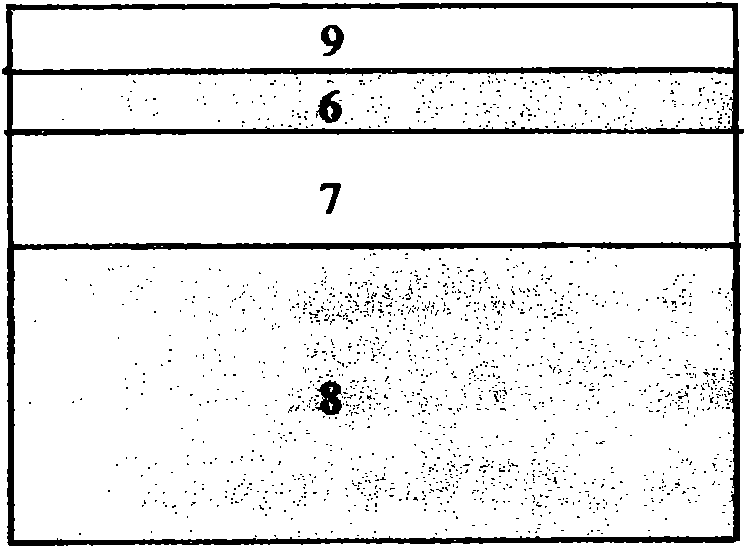

[0035] see figure 1 and figure 2 Shown, the present invention provides a kind of waveguide grating coupler with distributed Bragg reflector, and described coupler adopts the silicon material on the insulator, comprises:

[0036] A silicon substrate 8;

[0037] A confinement layer 7, the confinement layer 7 is made on the silicon substrate 8, the thickness of the confinement layer 7 is greater than 500nm, which can effectively prevent light from leaking to the silicon substrate 8;

[0038] A top silicon layer 6, the top silicon layer 6 is made on the confinement layer 7, a diffraction grating 3 is made on the surface of the top silicon layer 6, a reflection grating 4 is made on one side of the diffraction grating 3, and a reflection grating 4 is made on the side of the diffraction grating 3 The other side is a tapered waveguide 2, the tapered waveguide 2 is larger than 80 μm, which can realize lossless transmission in theory, and the connection with the tapered waveguide 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com