Helical water pump volute chamber structure of engine water pump

A screw type and engine technology, which is applied in the direction of machines/engines, liquid fuel engines, and components of pumping devices for elastic fluids, etc. It can solve the problems of increased power consumption of water pumps, increased fuel consumption of engines, and obvious water flow noise. Achieve the effect of reducing water flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

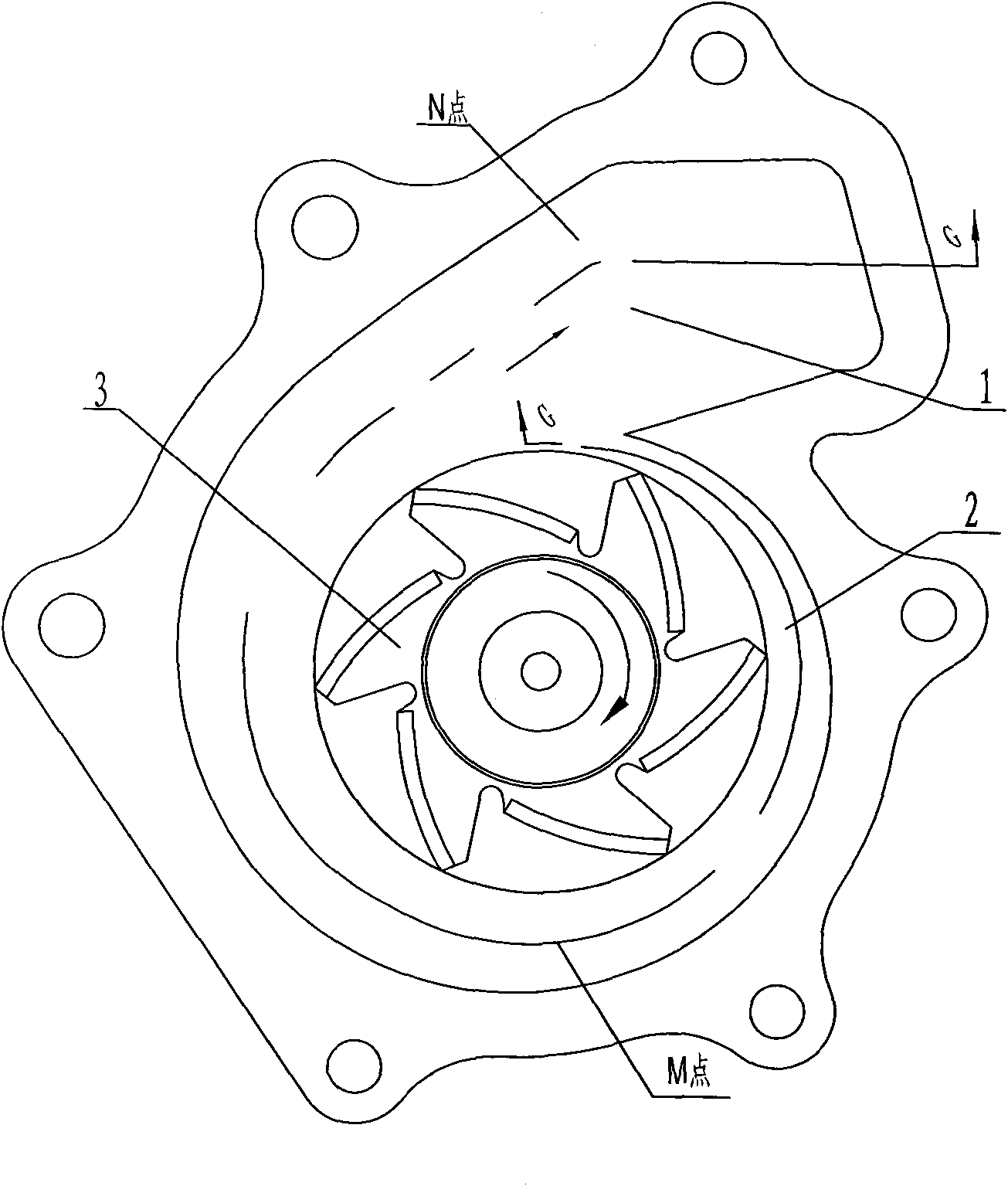

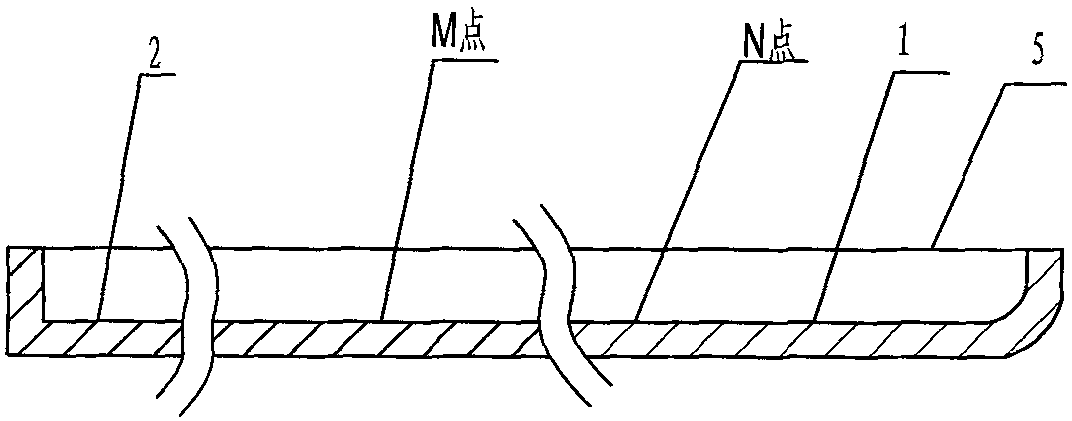

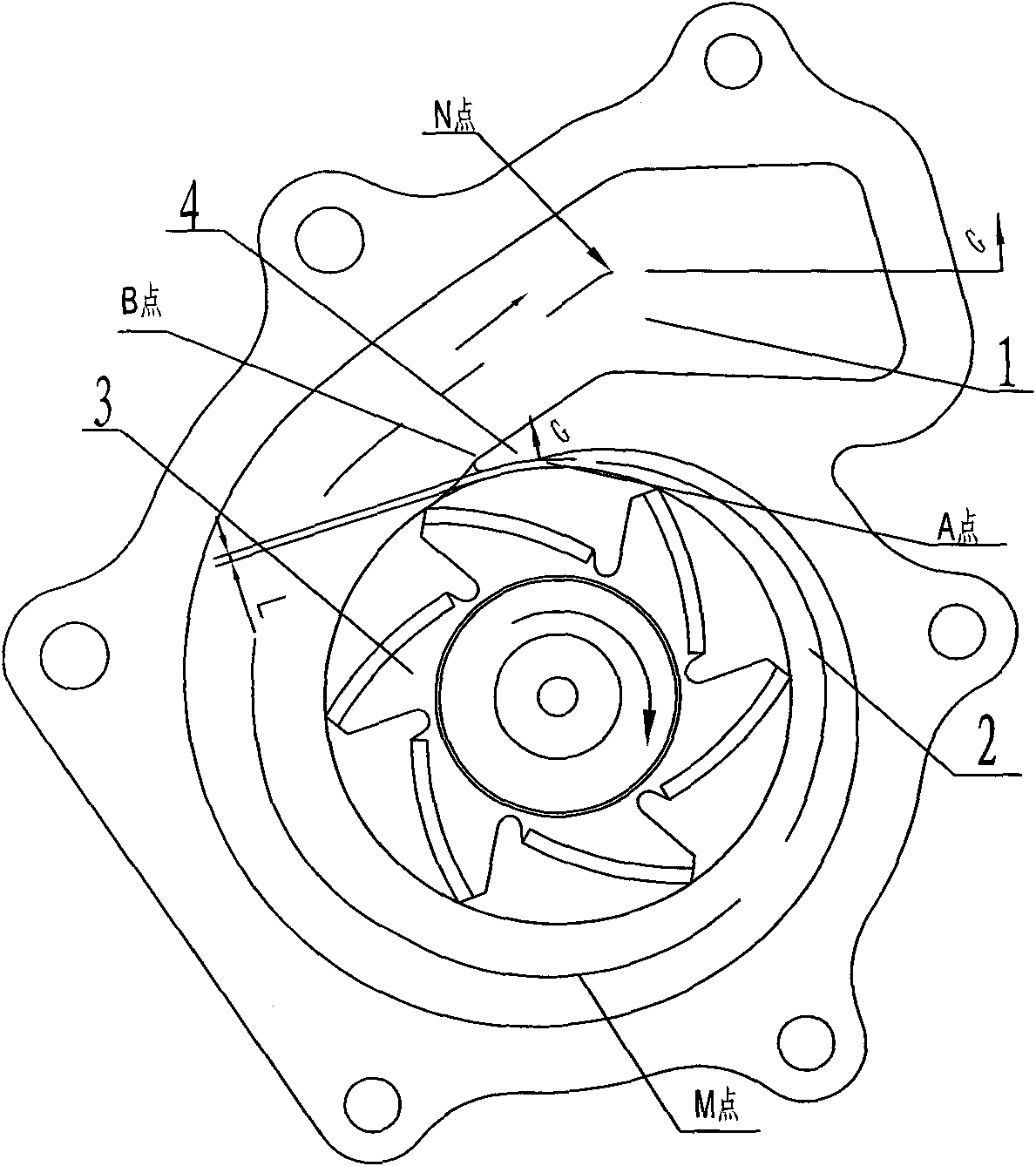

[0018] The structure of the vortex chamber of the spiral water pump is as follows: image 3 As shown: the vortex chamber is divided into three parts: the water outlet channel 1, the water inlet channel 2 and the tongue 4. The center of the vortex chamber is the area where the impeller 3 is installed. Between the contour line of the impeller rotation and the outer wall of the vortex, the impeller is surrounded to form a sequentially connected water inlet channel 2 and water outlet channel 1 in a spiral shape. The outer wall of the water inlet passage 2 of the vortex chamber is composed of 3 to 5 sections of arcs, and the diameter of the arcs gradually increases. At the same time, the dimension height from the bottom surface of the vortex chamber to the installation surface 5 of the pump body gradually deepens, such as Figure 4 Shown: Points M and N are respectively taken on the inlet and outlet channels of the vortex chamber. The cross-sectional heights of the two points are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com