Comprehensive utilization method and system for coal

A subsystem and pulverized coal technology, applied in the comprehensive utilization method and system field of coal, can solve the problems of inability to reduce carbon dioxide and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

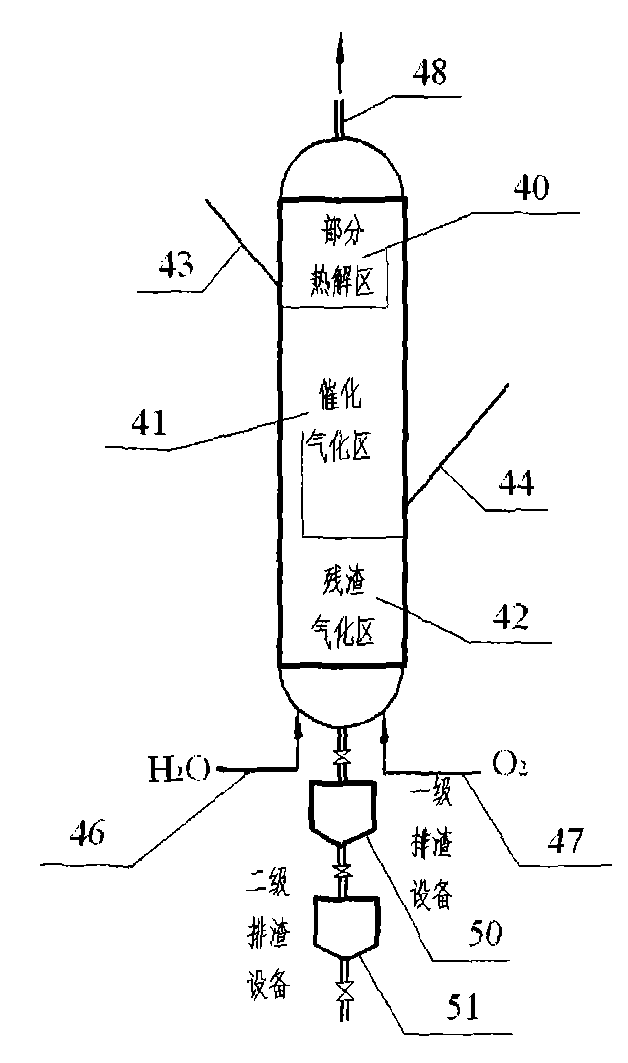

[0092] see figure 1 , figure 1The gasifier includes three zones from top to bottom, which are partial pyrolysis zone 40 , catalytic gasification zone 41 , and residue gasification zone 42 . The raw coal enters the partial pyrolysis zone 40 through the pipeline 43. The temperature of the partial pyrolysis zone 40 is 450-650°C. The gas stream from the catalytic gasification zone 41 heats the feed raw coal and pulverized coal in the partial pyrolysis zone 40 to make it generate Partial pyrolysis and hydropyrolysis to obtain methane-containing gas products, tar and pyrolyzed coal powder. The gaseous products and tars exit the gasifier in outlet line 48 to subsequent separation equipment. The pyrolyzed coal powder moves downward into the catalytic gasification zone 41 . Another part of coal and catalyst enters the catalytic gasification zone from the pipeline 44 in the form of mixture, and these coals, together with the pyrolyzed coal powder from the partial pyrolysis zone, are ...

Embodiment 2

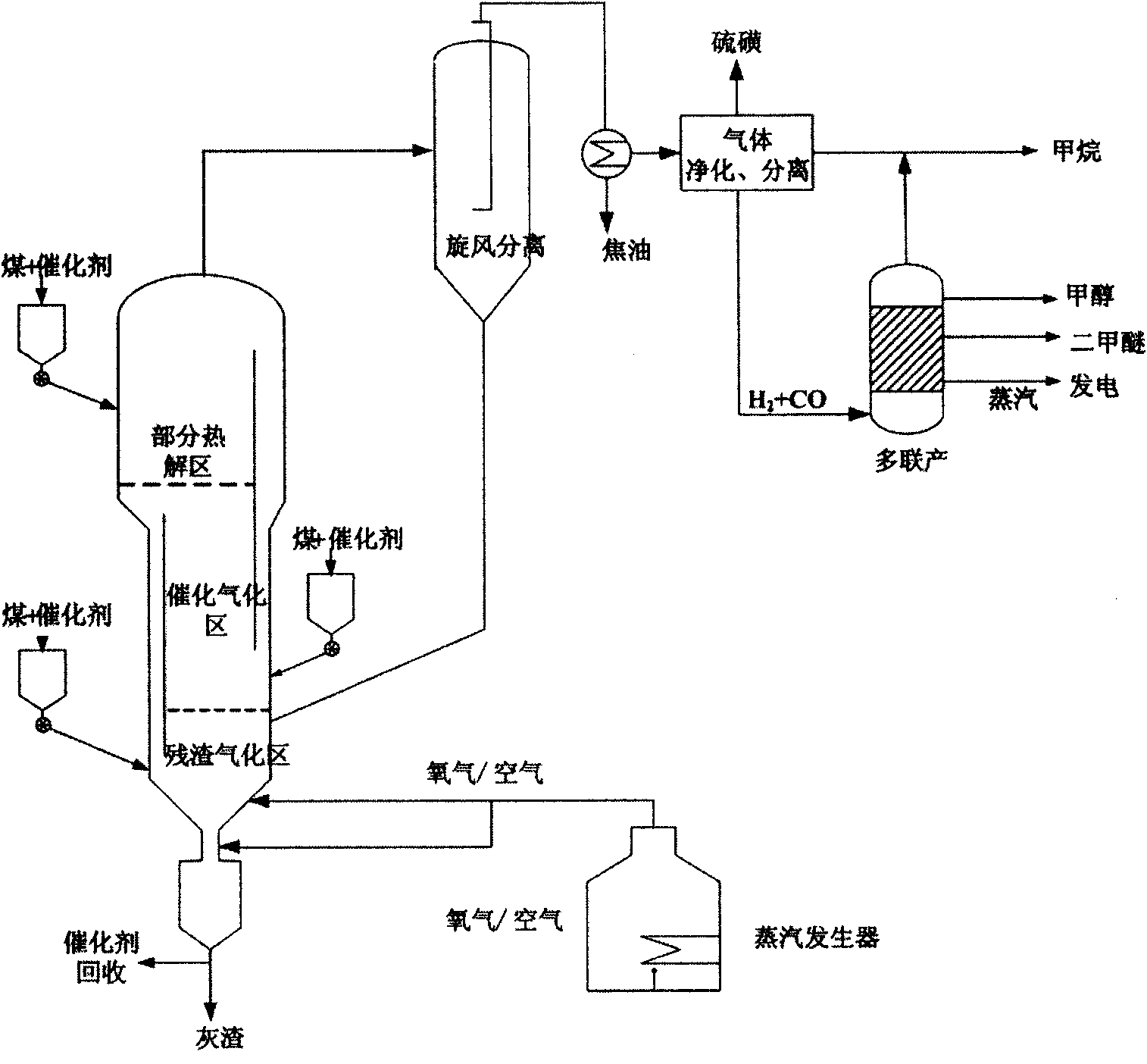

[0094] see Figure 4 , the outlet gas of the gasifier (mainly CH 4 , CO, H 2 and CO 2 , and a small amount of H 2 S and NH 3 etc.) through the isothermal dust filtration of the cyclone separator for gas-solid separation, the solid phase dust is returned to the gasifier for gasification reaction, and the gas phase is separated through the gas-liquid cooling separation unit for gas-liquid separation to obtain low-temperature tar. The crude synthesis gas is purified and separated to remove acid gases such as carbon dioxide and hydrogen sulfide to obtain methane. H separated from purification system 2 S is further processed to obtain sulfur. Remaining H 2 and CO into polygeneration sub-methods for the production of methane, methanol, dimethyl ether and the like. The steam produced by the polygeneration sub-process is used to generate electricity.

Embodiment 3

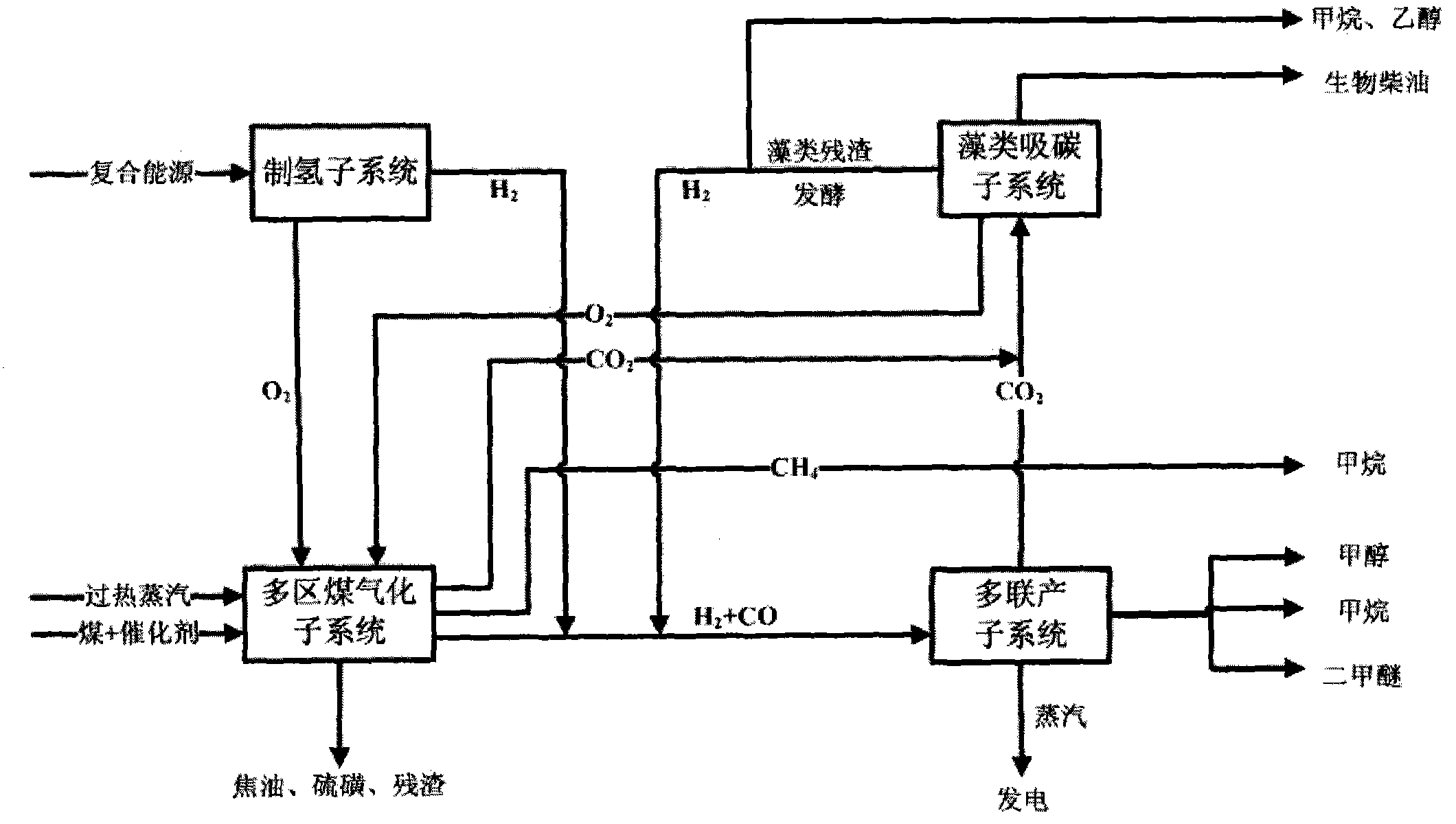

[0096] see figure 2 , the crude syngas produced by the multi-zone coal gasification sub-method is purified and separated from methane to produce syngas (mainly H 2 and CO) and the hydrogen of the hydrogen production method and the by-product hydrogen produced by the residue fermentation of the algae carbon absorption method are mixed, and sent to the multi-generation method, a part of which is directly methanated to produce methane, and the by-product water is returned to the multi-zone coal gasification method ; Another part of methanol is synthesized, a part of the produced methanol is used to produce dimethyl ether, and the other part can be sold directly. The carbon dioxide generated by the multi-zone coal gasification method and the polygeneration method is sent to the algae carbon absorption method to produce biodiesel, and at the same time, oxygen is co-produced. The algae residue is used for fermentation to produce one or more of the by-product hydrogen, methane or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com