Electric or solar highway-railway combined automobile and line thereof

A road-rail dual-use, solar energy technology, applied in electric vehicles, rail and road dual-use vehicles, motor vehicles, etc., can solve the problems of limited space for steel wheel installation, low chassis, steel wheel collision, etc., and achieve resource saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

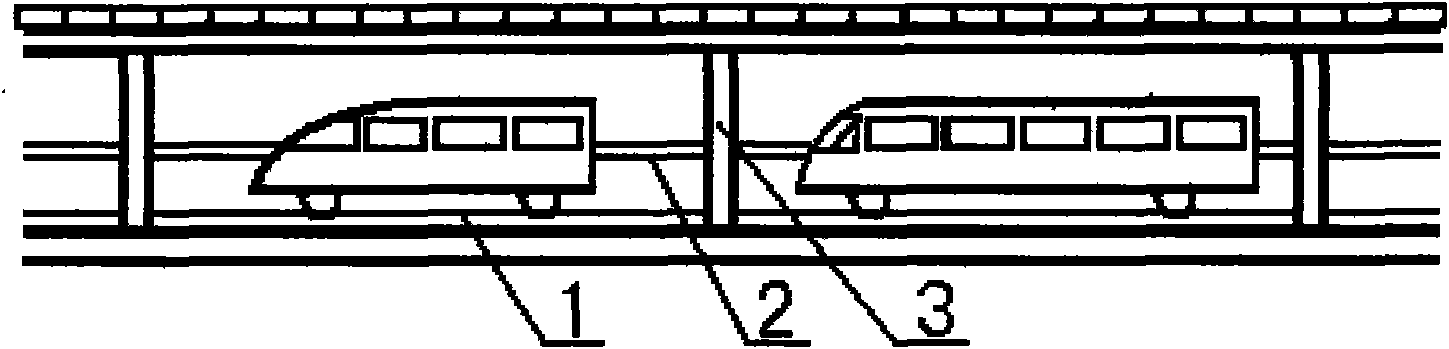

[0049] figure 1 As shown in , the solar panel 4 is installed above the track line 1 through the mounting frame 3, and the road-rail vehicle running on the track line contacts the power supply rail 2 installed on the side of the mounting frame 3 through the collector 5 on one side. Power the vehicle. The track line adopts regional segmentation independently, and the solar battery directly supplies power to the vehicle through the power supply rail; according to the current general solar battery, it can generate 0.2kw of power per square meter area, and a solar panel with a width of 3m is laid above the track, which is independent every 1km The 3,000-square-meter solar panels above the power supply section can generate 600kw of electricity. When the speed of the vehicle running on orbit is 100-120km per hour, the driving power of 1t weight needs 3-4kw; under the condition of sufficient light, the power generated by the independent power supply interval per km can theoretically ...

Embodiment 2

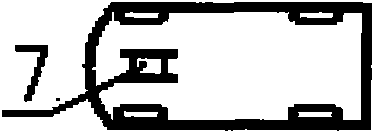

[0056] image 3 As shown, the longitudinal center line of the front end of the automobile chassis is equipped with independent steel wheels 7 with guide rims on both sides, and the road surface monorail 10 ( Figure 9 Shown) the contact on both sides, guide and load automobile 12 front end weights for vehicle running, and vehicle is driven on track circuit by running on the rear rubber wheel on rail both sides road surface 11. For the convenience of the steel wheel entering the rail, the front end of the rail 10 is pointed

[0057] Figure 4 As shown, independent steel wheels 7 with guide rims on both sides are installed on the longitudinal centerlines of the front and rear ends of the automobile chassis. When the steel wheels run on the rails, most of the weight of the vehicle is borne by the steel wheels. The guide, driven by rubber drive wheels still in contact with the road surface 11 on both sides of the rail, runs on the track circuit. In application, when the front a...

Embodiment 3

[0066] Figure 10 and Figure 12 As shown in , the front end of the monorail track circuit is respectively provided with small sections of entry rails 13 and 18, and the rear ends of the entry rails 13 and 18 are rotatably installed on the front end of the monorail or the road surface at the front end of the monorail, and the front end of the entry rail can slide laterally through the slide plate 14 below it. installed on the sliding seat 15; the entry rails 13 and 18 actively detect the lateral position of the automobile or automobile steel wheel through the position sensors or distance sensors 16 arranged on the front or on both sides, and are driven into the rail by the servo device (point switch). The front end moves horizontally to align the steel wheel, so that the steel wheel of the automobile can smoothly drive up the entry rail, and enter the rail line through the entry rail. Figure 13-1 Shown as the front ends of the two rails of the narrow-gauge line are also resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com