Stripping debonding and packaging method used for preparing graphene via continuous adhesive tape method

A packaging method and graphene technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problem of difficult to observe peeling and degumming, grasping packaging, difficult to enter the industrial production sequence, and the continuous tape method is rarely used. and other problems, to achieve the effect of simple structure, orderly arrangement and small size of equipment and tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail as follows:

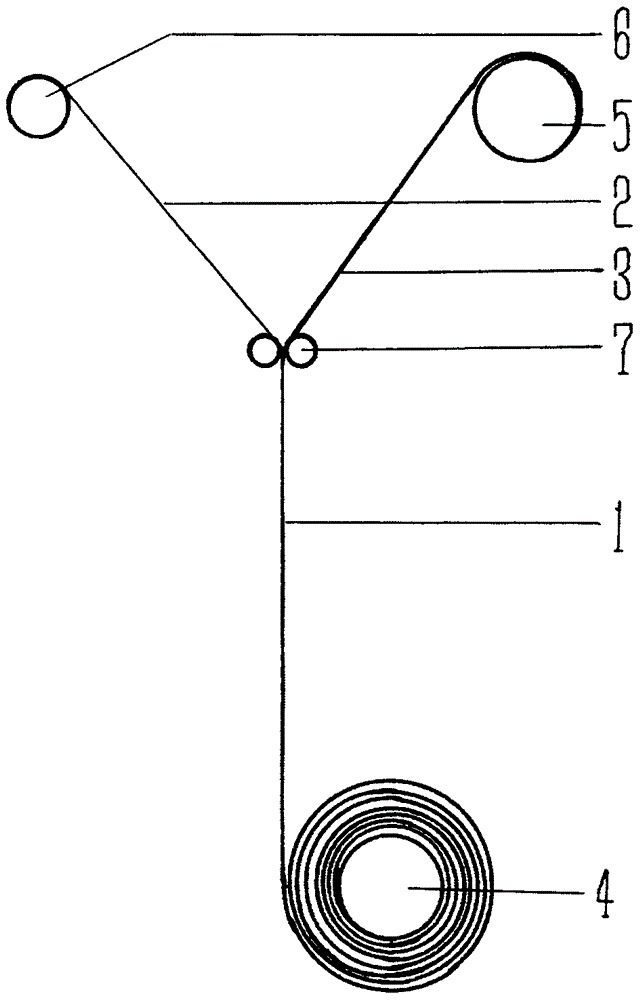

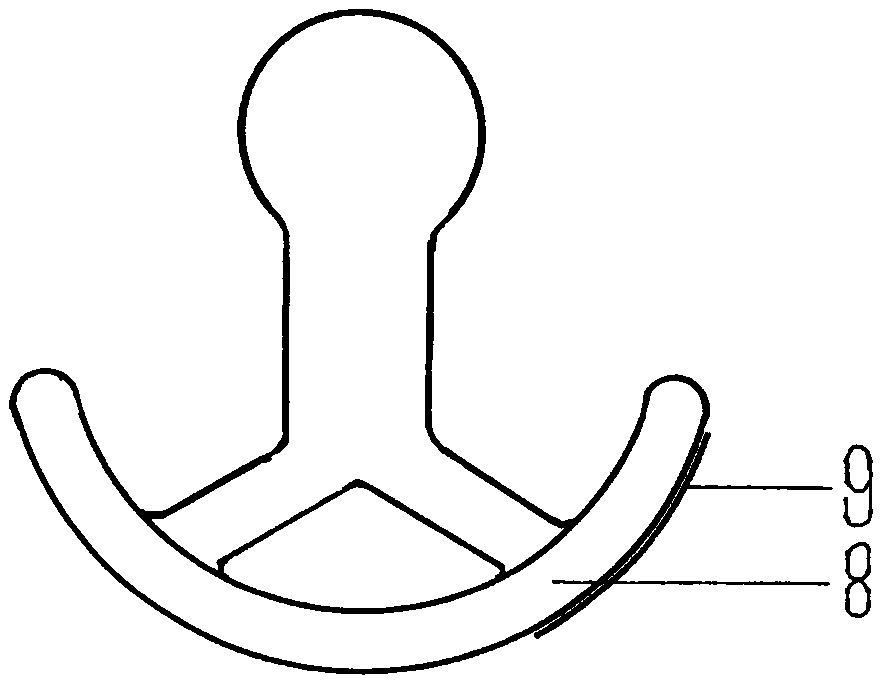

[0020] Such as figure 1 , figure 2 As shown, the peeling mechanical device of the present invention includes an adhesive tape reel A4, an adhesive tape reel B5, a graphene reel 6 and an orientation roller 7 installed on the overall frame. The above-mentioned shafts and rollers are parallel to each other, the tape reel B5 and the graphene reel 6 are power rollers driven by a synchronous variable speed DC motor, the tape reel A4 is a passive roller, and the directional rollers 7 are elastically combined and installed on the frame as a whole to move up and down On the slot of the position, the sticking and removing hand roller 8 is an arc section roller, and the arc is provided with a hand tool for grasping the handle.

[0021] During production and application, one set of prepared graphene tape is fixed on the tape reel A, and the lead-out end passes throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com