Mountain stone plane cutting saw

A technology for cutting saws and stone, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of increasing production costs, high labor intensity, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

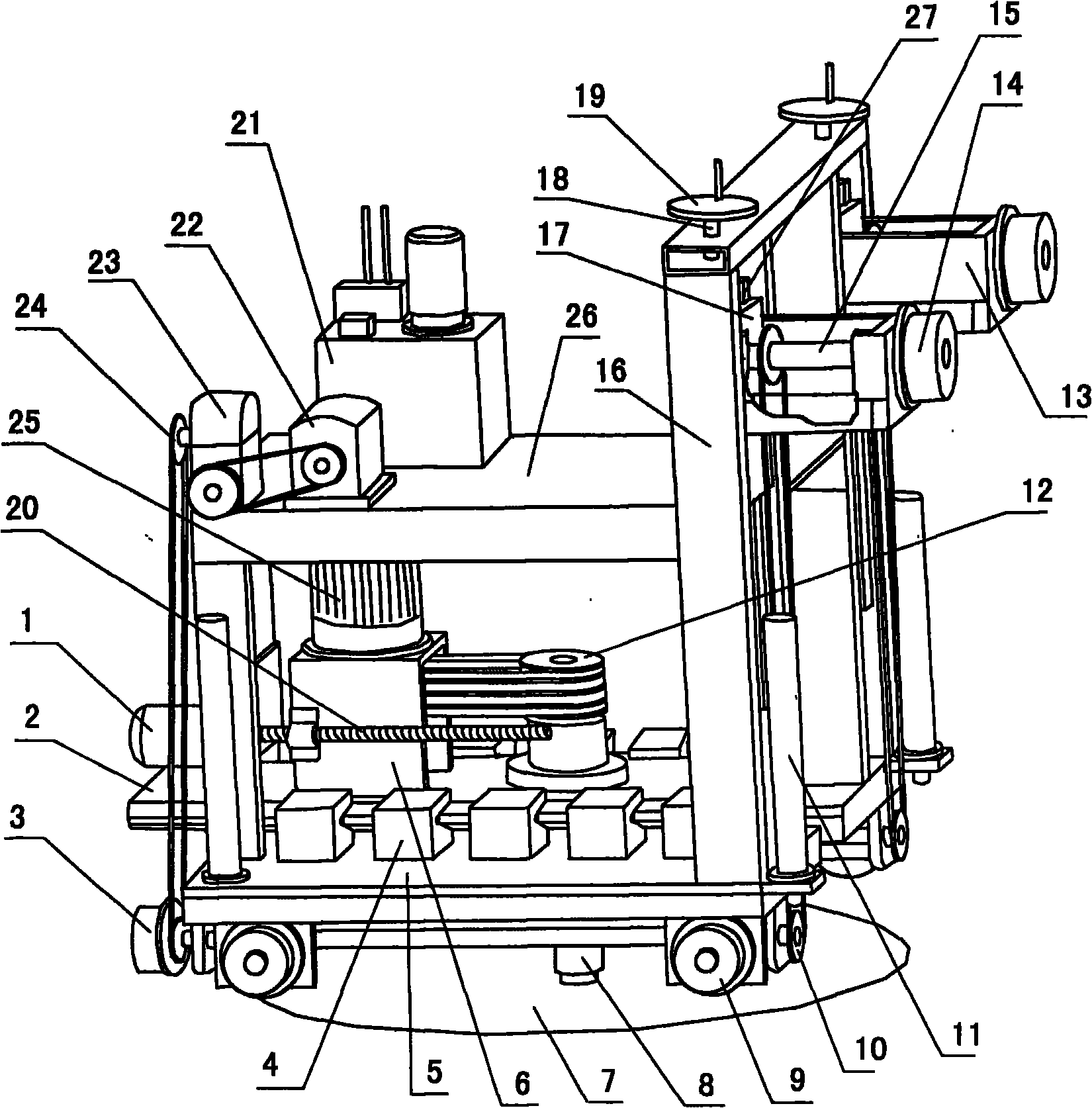

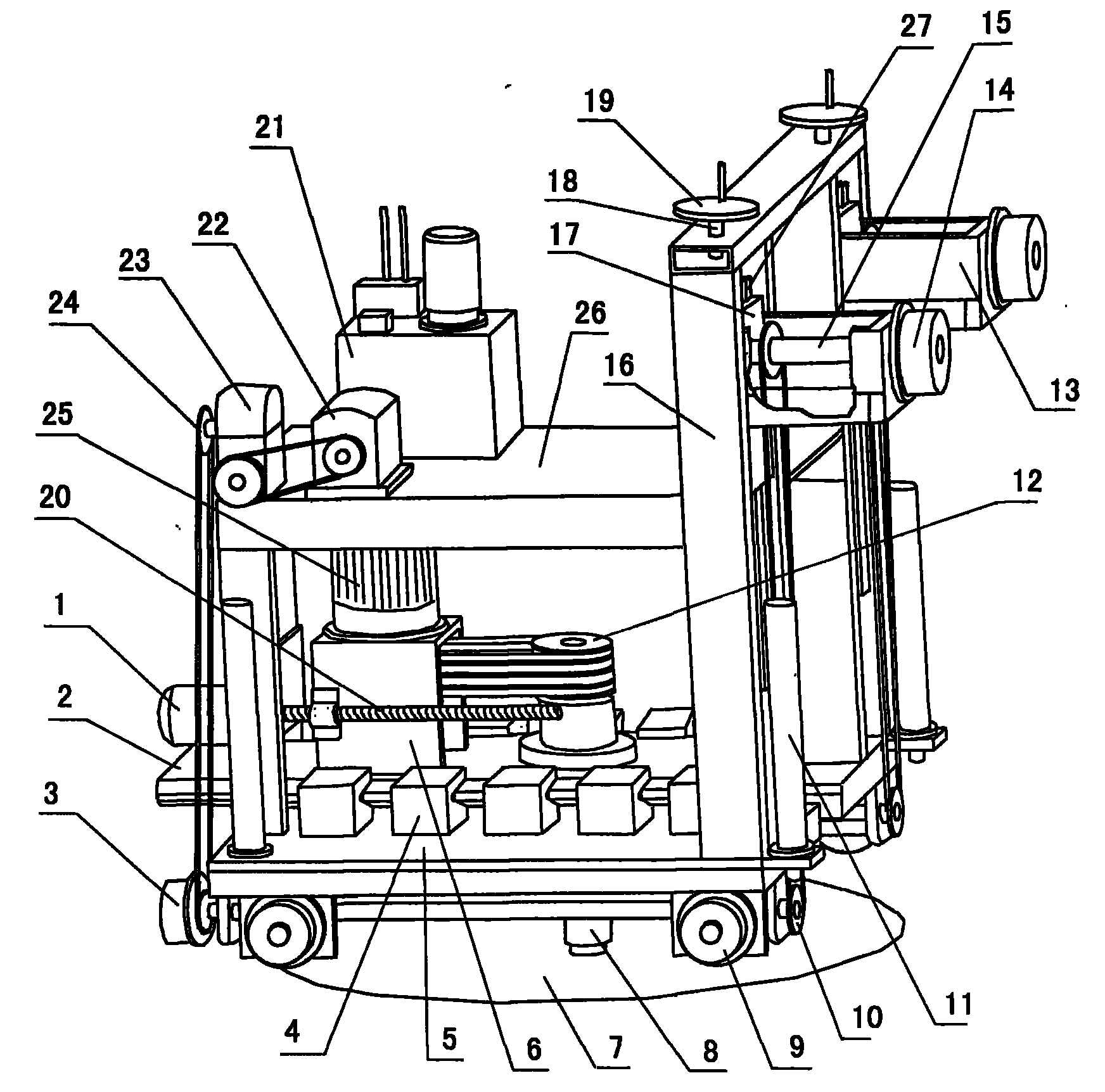

[0008] Structure of the present invention is as shown in accompanying drawing: a chassis 5 is arranged at the bottom of body support 16. There are two combined fixed slideways 4 in the middle part of the chassis. There is a moving slideway 2 between the two fixed slideways. There is a main motor support 6 on the moving slideway. There is a main motor 25 on the main motor support. There is a saw blade main shaft 8 on one side of the main motor, and there is a main shaft belt pulley 12 on the top of the saw blade main shaft. The main shaft pulley is connected with the pulley on the output shaft of the main motor. There is a saw blade 7 at the lower end of the saw blade main shaft. There is a moving slideway to advance the cycloidal motor 1 at the rear portion of the main body support. There is a helical shaft 20 on the output shaft of the moving slideway advancing cycloidal motor. The screw shaft is connected with the main motor support through a nut. There is an upper pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com