Impregnant for impregnated grinding wheels and application thereof in preparing impregnated grinding wheels

An impregnation and grinding wheel technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve undisclosed problems and achieve the effects of prolonging the life of the grinding wheel, inhibiting metal adhesion, and reducing the grinding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

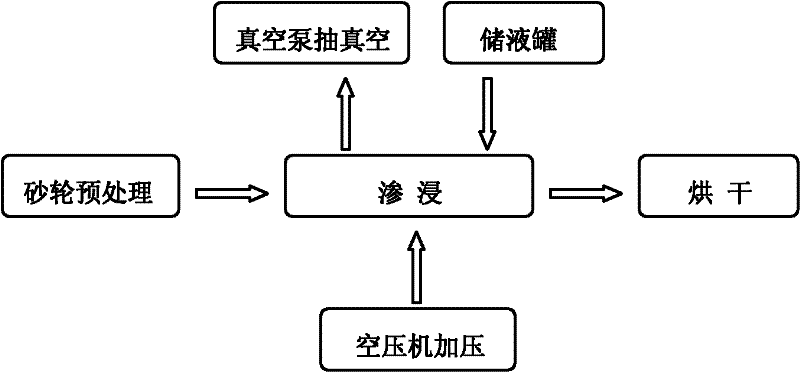

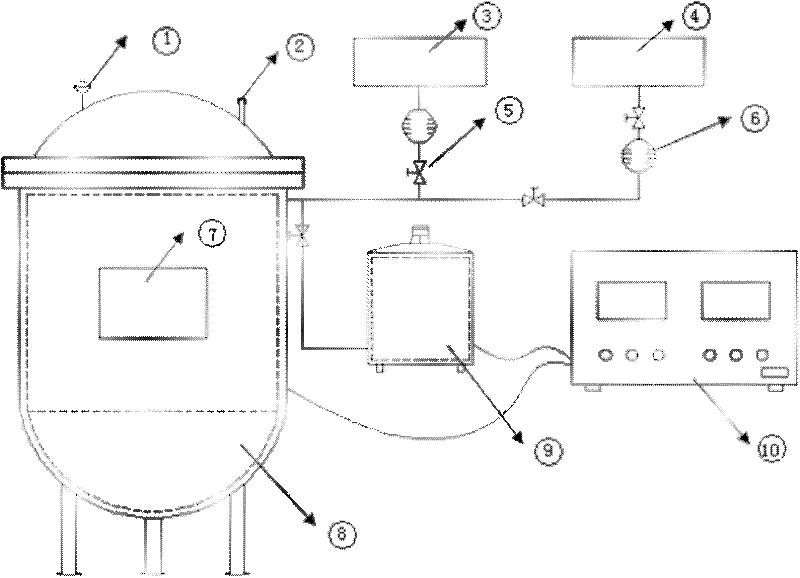

Method used

Image

Examples

Embodiment 1

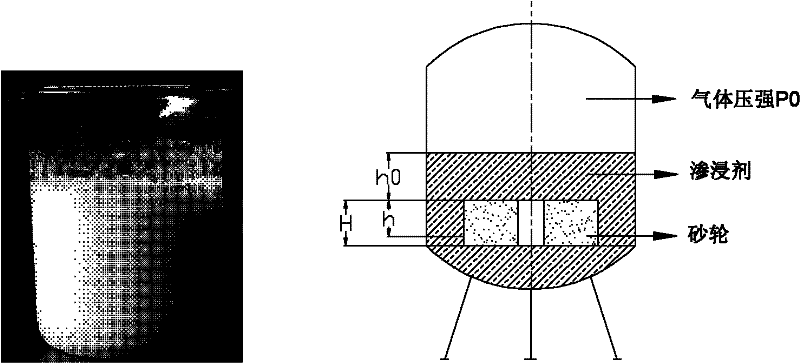

[0038]Embodiment 1: The impregnation experiment parameter of impregnation emery wheel is as shown in table 1:

[0039] Table 1 Immersion test parameters

[0040]

[0041] The mass percentage of each component in the impregnating agent is: paraffin 1%, molybdenum disulfide 0.2%, triethanolamine 0.7%, oleic acid 1.4%, tributyl phosphate 0.45%, sodium molybdate 0.1%, sodium chloride 0.5%, Sodium carbonate 0.1%, the balance is water.

[0042] The workpiece is ground on the MA6025 universal tool grinding machine. The grinding wheel speed of the machine tool is 2700rpm, the workpiece speed is 170rpm, and the manual feed speed is 1.5mm / min. The measured roughness, grinding ratio and material removal rate are shown in Table 2:

[0043] Table 2 Comparison of roughness, grinding ratio and material removal rate

[0044]

Embodiment 2

[0045] Embodiment 2: The impregnation experiment parameter of impregnation emery wheel is as shown in table 3:

[0046] Table 3 impregnation test parameters

[0047]

[0048] The percentage of each component in the impregnating agent is: 2.2% paraffin, 2.2% molybdenum disulfide, 3% triethanolamine, 2% oleic acid, 1.25% tributyl phosphate, 1.25% sodium molybdate, 2% sodium chloride, carbonic acid Sodium 1%, balance water.

[0049] The workpiece is ground on the MA6025 universal tool grinding machine. The grinding wheel speed of the machine tool is 2700rpm, the workpiece speed is 170rpm, and the manual feed speed is 1.5mm / min. The measured roughness, grinding ratio and material removal rate are shown in Table 4:

[0050] Table 4 Comparison of roughness, grinding ratio and material removal rate

[0051]

Embodiment 3

[0052] Embodiment 3: the preferred impregnation experiment parameter of impregnation grinding wheel is as shown in table 5:

[0053] Table 5 impregnation test parameters

[0054]

[0055] The percentage of each component in the preferred impregnating agent is: paraffin 1.8%, molybdenum disulfide 0.9%, triethanolamine 1.85%, oleic acid 1.85%, tributyl phosphate 0.65%, sodium molybdate 0.3%, sodium chloride 1.2% , 0.45% sodium carbonate, and the balance is water.

[0056] The workpiece is ground on the MA6025 universal tool grinding machine. The grinding wheel speed of the machine tool is 2700rpm, the workpiece speed is 170rpm, and the manual feed speed is 1.5mm / min. The measured roughness, grinding ratio and material removal rate are shown in Table 6:

[0057] Table 6 Comparison of roughness, grinding ratio and material removal rate

[0058]

[0059] Workpiece surface burns: Under the same grinding conditions, the impregnated grinding wheel can significantly improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com