Industrial organic exhaust gas active-carbon bed plasma integrated purification technology and device thereof

A technology of organic waste gas and purification device, which is applied in the direction of combined device, separation method, and dispersed particle separation, etc., which can solve the problems of secondary pollution, large air volume, waste gas purification efficiency, reduction of adsorption equipment volume, and reduction of adsorbent filling volume. Achieve the effect of simple operation, avoiding secondary pollution problems, and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

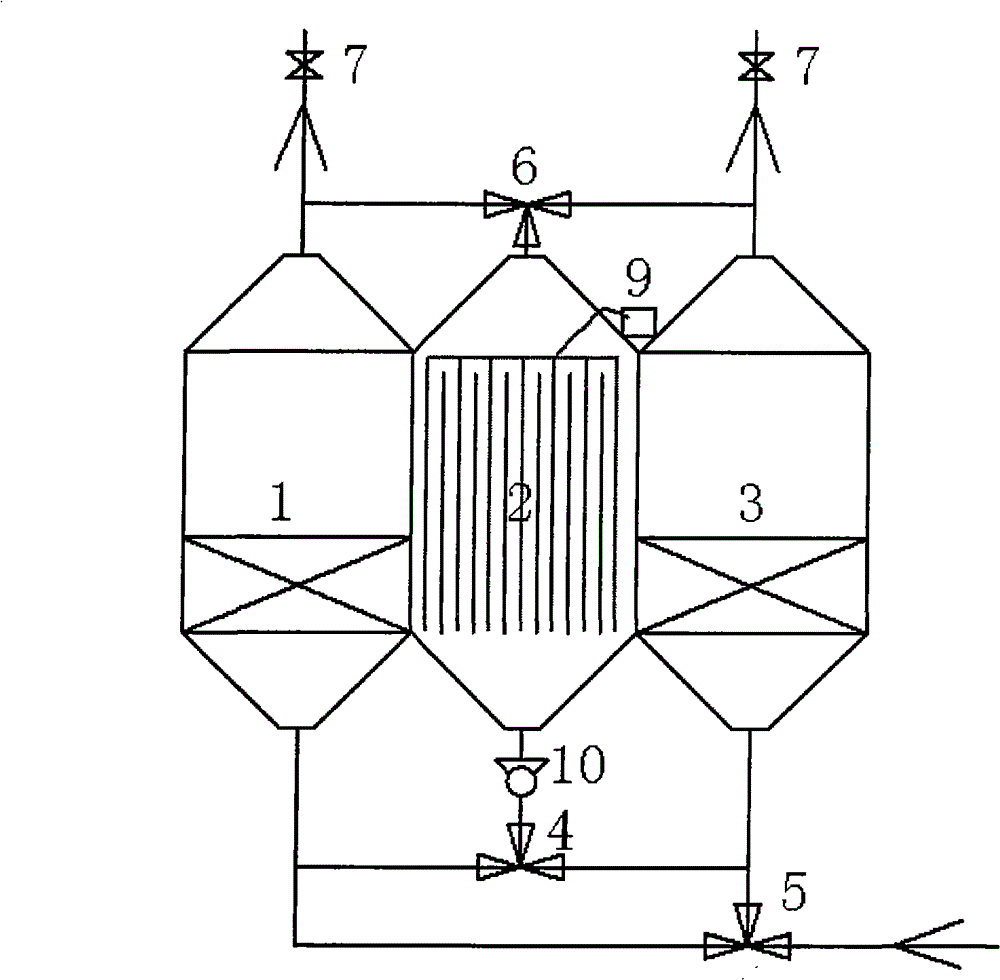

[0017] refer to figure 1 , an industrial organic waste gas purification device, comprising activated carbon adsorption tanks 1, 3 and flat-plate low-temperature plasma 2, the activated carbon adsorption tanks 1, 3 are switched and used alternately through a three-way valve 5, filled with activated carbon as an adsorbent, filled with The amount of activated carbon required for the purification of organic waste gas produced in 2-3 days of normal production. After the adsorption tanks 1 and 3 are saturated, the three-way valves 4 and 6 are switched to form a desorption regeneration cycle system with the plasma 2, and the fan 10 is used for suction. The activated carbon is desorbed, and the desorbed concentrated gas is sent to the plasma for purification, and the ozone-rich tail gas from the plasma is passed into the activated carbon tank in the regeneration process, and the activated carbon is regenerated and activated by ozone. Wherein, the backstop damper 7 is in an open state ...

Embodiment 2

[0019] refer to figure 1 , applied to the paint waste gas purification process equipment in the bicycle paint spray room, including activated carbon adsorption tanks 1, 3 and low-temperature plasma 2, the low-temperature plasma 2 is cylindrical and designed as a tubular heat exchanger, and the high-temperature paint waste gas first enters the exchange The thermal low-temperature plasma 2 heats the gas in the desorption cycle system to accelerate the desorption of the saturated activated carbon bed, and the cooled paint exhaust gas is sent to another activated carbon bed for adsorption and purification. The activated carbon adsorption tanks 1 and 3 are used alternately. Activated carbon is filled as an adsorbent, and the operation process refers to Example 1.

Embodiment 3

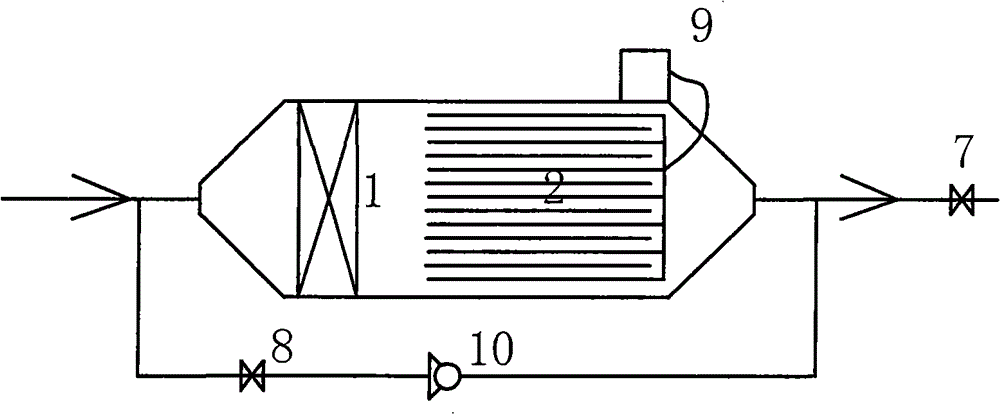

[0021] refer to figure 2 , used in an organic waste gas purification device that allows intermittent operation in production. The system consists of an activated carbon bed 1 and a low-temperature plasma 2 connected in series. The activated carbon bed 1 is filled with the amount of activated carbon required for the adsorption of organic waste gas during normal production for 2 to 3 days. During the adsorption and purification process of the activated carbon bed 1, the backstop damper 7 is in an open state, and the backstop damper 8 is in a closed state. When desorbing, turn on the fan 10, due to the suction effect of the fan, the backstop damper 7 is in a closed state, the backstop damper 8 is opened, and the space of the plasma 2 becomes a closed negative pressure zone, and the activated carbon bed 1 is desorbed under negative pressure, and the desorption The attached waste gas is purified in the plasma 2 area, and the ozone-rich tail gas is sent to the activated carbon bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com