A method for preparing gold-coated nano-magnetic particles for preparing magnetic liquids

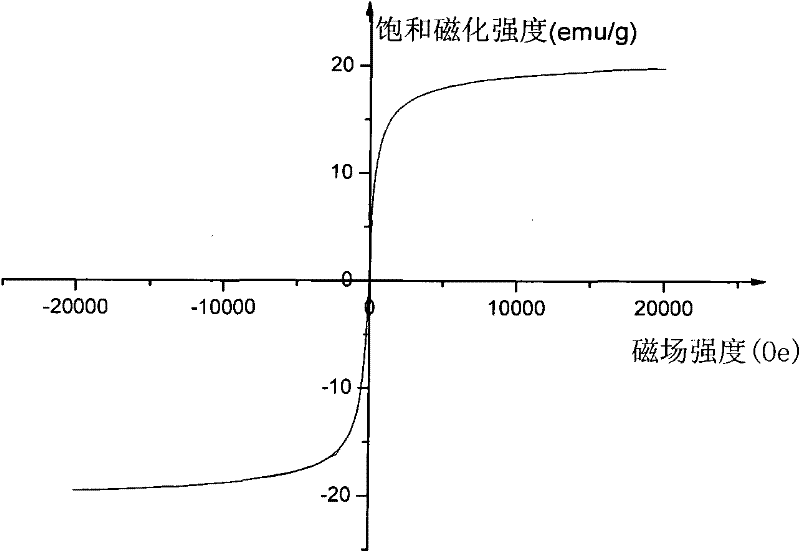

A magnetic particle and nano-magnetic technology, which is applied in the direction of magnetic liquid, magnetic objects, magnetic materials, etc., to achieve the effect of high magnetization strength, small coercive force, and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

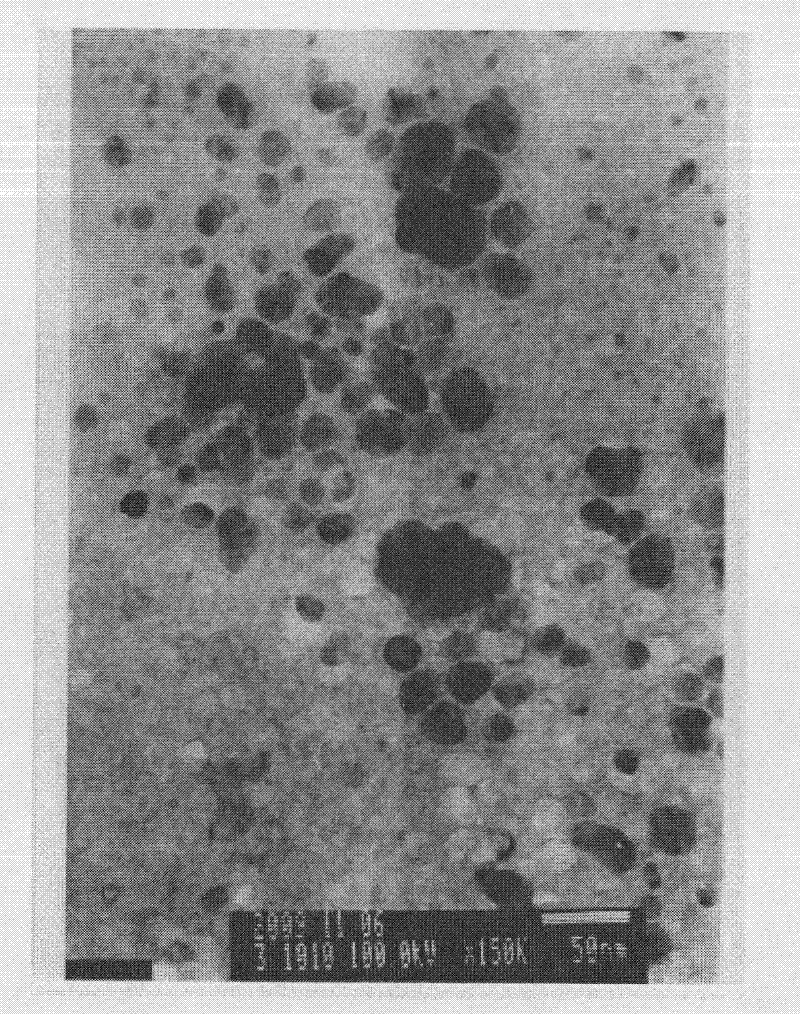

[0028] A method for preparing a gold-coated nano-magnetic particle for preparing a magnetic liquid, the preparation method comprising the following steps:

[0029] In step 1, the mass ratio of ferric iron tetroxide nano-magnetic particles to chloroauric acid is 1:10, and the mass ratio of chloroauric acid to sodium citrate is 1:36.9.

[0030] Weigh 0.1 g of dried iron ferric oxide nano-magnetic particles, 1 g of chloroauric acid, and 36.9 g of sodium citrate.

[0031] The chloroauric acid 1g that weighs is mixed with molar concentration and is 80mmol / L chloroauric acid solution.

[0032] The sodium citrate 36.9g that will take by weighing is mixed with molar concentration and is 2.5mol / L sodium citrate solution.

[0033] Step 2, dissolving 0.1 g of iron ferric oxide nano-magnetic particles weighed in absolute ethanol, and ultrasonically dispersing in an ultrasonic cleaner until the magnetic particles are completely dispersed.

[0034] Step 3, add 0.4ml of 3-aminopropyltrieth...

Embodiment 2

[0038] A method for preparing a gold-coated nano-magnetic particle for preparing a magnetic liquid, the preparation method comprising the following steps:

[0039] In step 1, the mass ratio of ferric iron tetroxide nano-magnetic particles to chloroauric acid is 1:0.5, and the mass ratio of chloroauric acid to sodium citrate is 1:7.4.

[0040] Weigh 1 g of dried iron ferric oxide nano-magnetic particles, 0.5 g of chloroauric acid, and 3.7 g of sodium citrate.

[0041] The chloroauric acid 0.5g that weighs is mixed with molar concentration and is 48.6mmol / L chloroauric acid solution.

[0042] The sodium citrate 3.7g that takes by weighing is formulated and made into molar concentration and is 1mol / L sodium citrate solution.

[0043] Step 2, dissolving 1 g of iron ferric oxide nano-magnetic particles weighed in absolute ethanol, and ultrasonically dispersing in an ultrasonic cleaner until the magnetic particles are completely dispersed.

[0044] Step 3, add 1ml 3-aminopropyltri...

Embodiment 3

[0048] A method for preparing a gold-coated nano-magnetic particle for preparing a magnetic liquid, the preparation method comprising the following steps:

[0049] Step 1: The mass ratio of iron ferric oxide nano-magnetic particles to chloroauric acid is 1:0.5, and the mass ratio of chloroauric acid to hydroxylamine hydrochloride is 1:5.6.

[0050] Weigh 1 g of dried iron ferric oxide nano-magnetic particles, 0.5 g of chloroauric acid, and 2.8 g of hydroxylamine hydrochloride.

[0051] The chloroauric acid 0.5g that weighs is mixed with molar concentration and is 48.6mmol / L chloroauric acid solution.

[0052] The hydroxylamine hydrochloride 2.8g that weighed is formulated and made molar concentration and is 0.1mol / L hydroxylamine hydrochloride solution.

[0053] Step 2, dissolving 1 g of iron ferric oxide nano-magnetic particles weighed in absolute ethanol, and ultrasonically dispersing in an ultrasonic cleaner until the magnetic particles are completely dispersed.

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com