Detecting equipment and detecting method of infrasound

A detection equipment and infrasound technology, applied in the detection field, can solve the problems of poor anti-electromagnetic interference ability, performance and use limitations, and potential dangers of electrical parameter sensors, and achieve the effects of low processing accuracy, simple structure and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

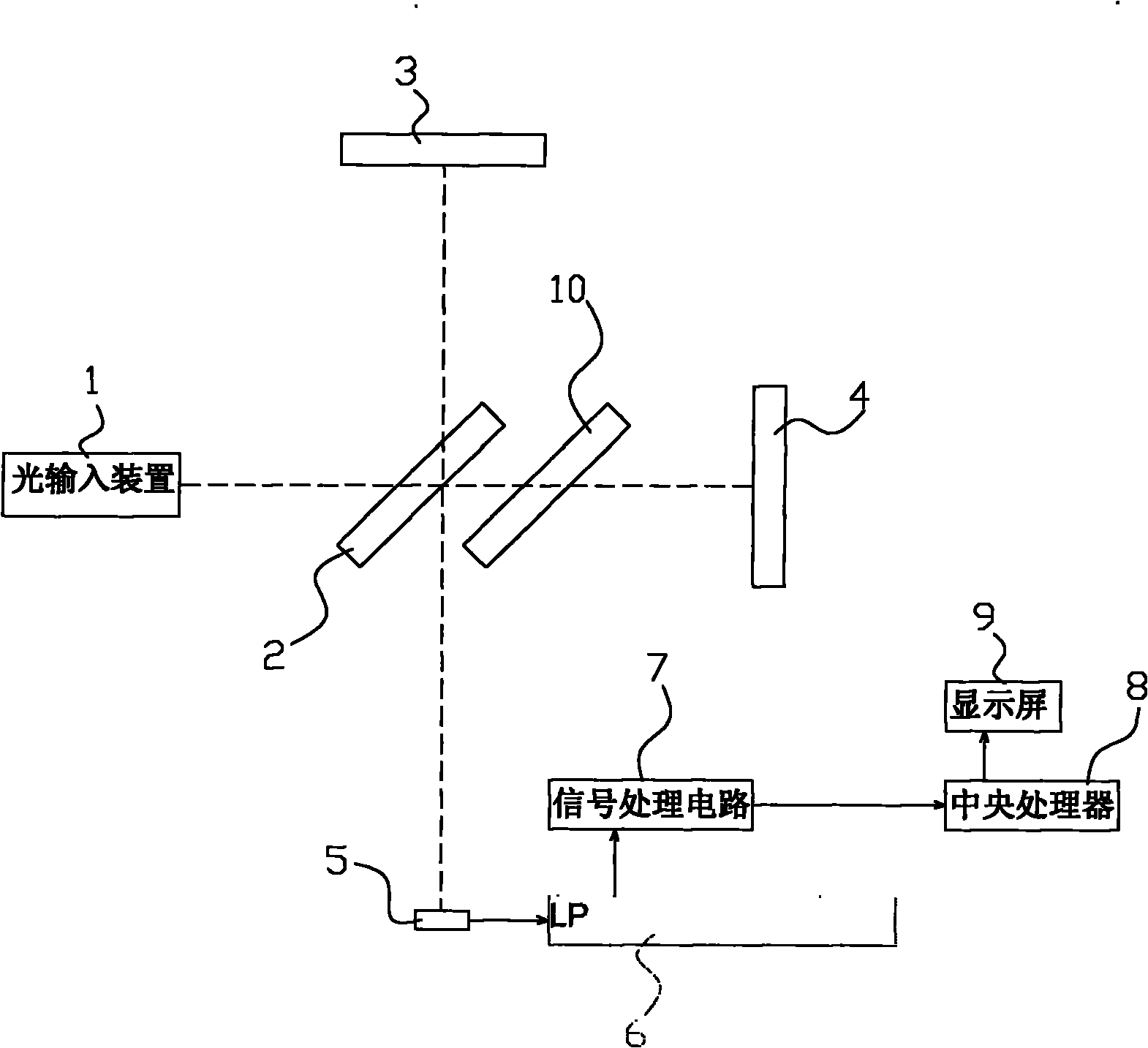

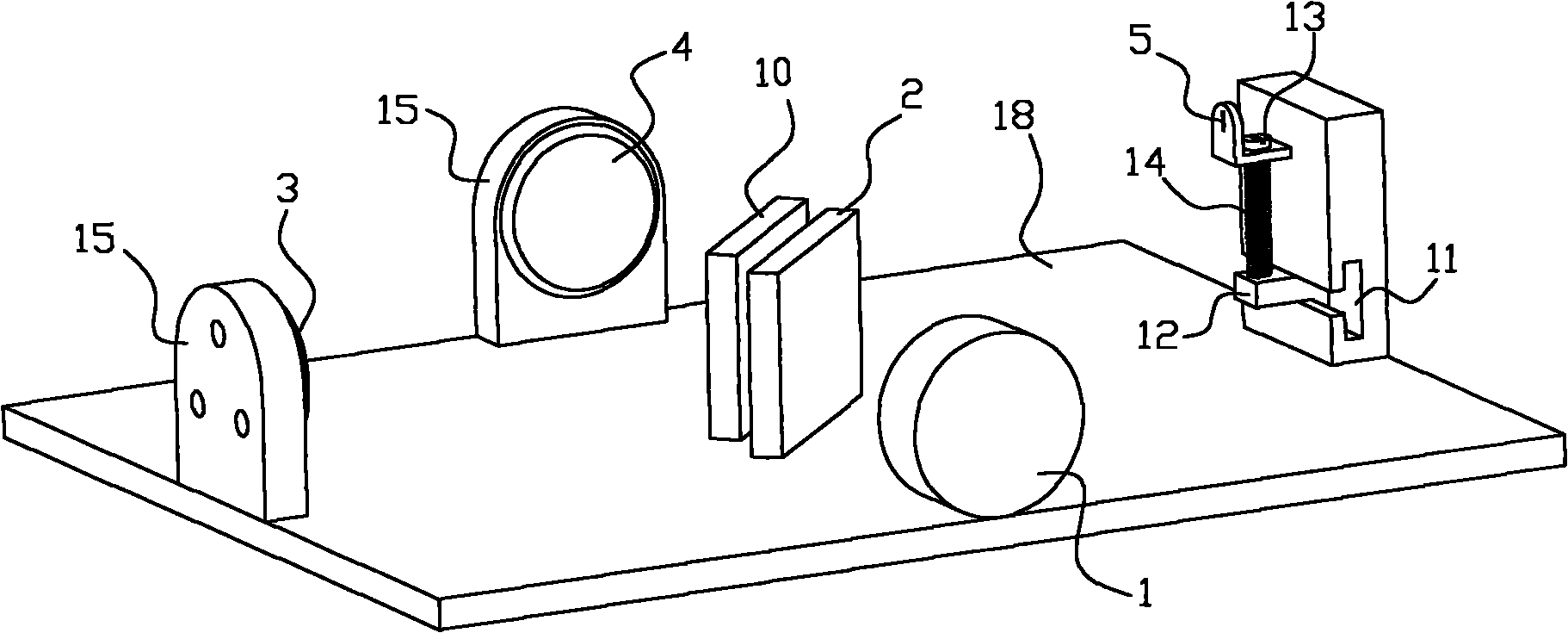

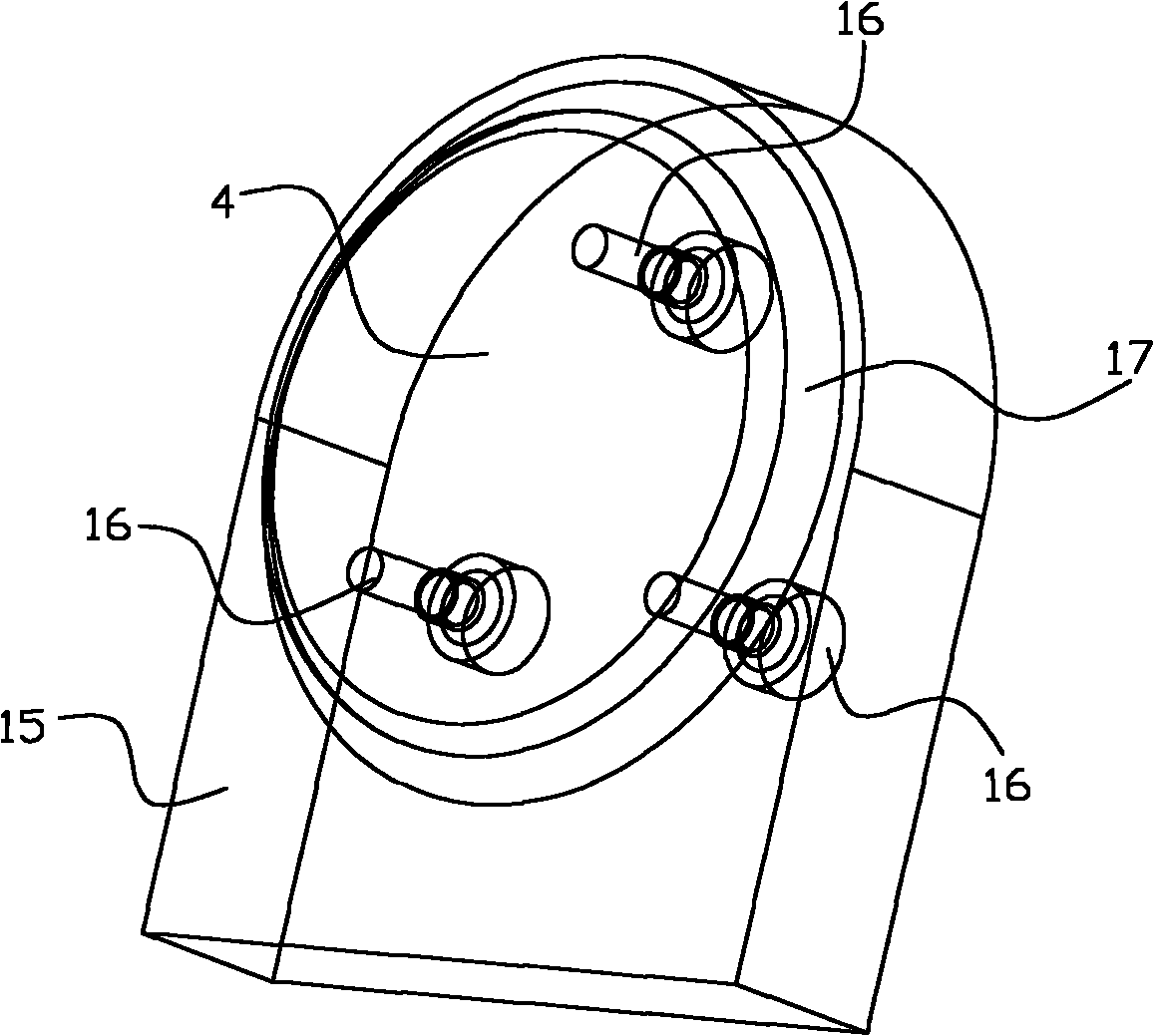

[0030] Such as Figure 1 to Figure 3 As shown, an infrasound detection device includes an optical input device 1, a beam splitter 2, a reflector 3, a detection mirror 4, a light detection element 5 and a signal processing device; the detection mirror 4 is installed on the base through an infrasonic vibration ring 17 18, the detection mirror 4 is opposite to the optical input device 1, the reflection mirror 3 is opposite to the light detection element 5, and the connection line between the detection mirror 4 and the light input device 1 is perpendicular to the connection line between the reflection mirror 3 and the light detection element 5, and The connecting line between the detection mirror 4 and the optical input device 1 and the connecting line between the reflecting mirror 3 and the light detecting element 5 are at an angle of 45 degrees relative to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com