Evaporative cooling and air-cooled heat pump type composite water chiller-heater unit

A cold and hot water unit, evaporative cooling technology, applied in heating methods, lighting and heating equipment, space heating and ventilation, etc., can solve the problems of high temperature cold water temperature stability, inability to meet winter air conditioning hot water, use restrictions, etc. To achieve the effect of improving condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the drawings and specific embodiments.

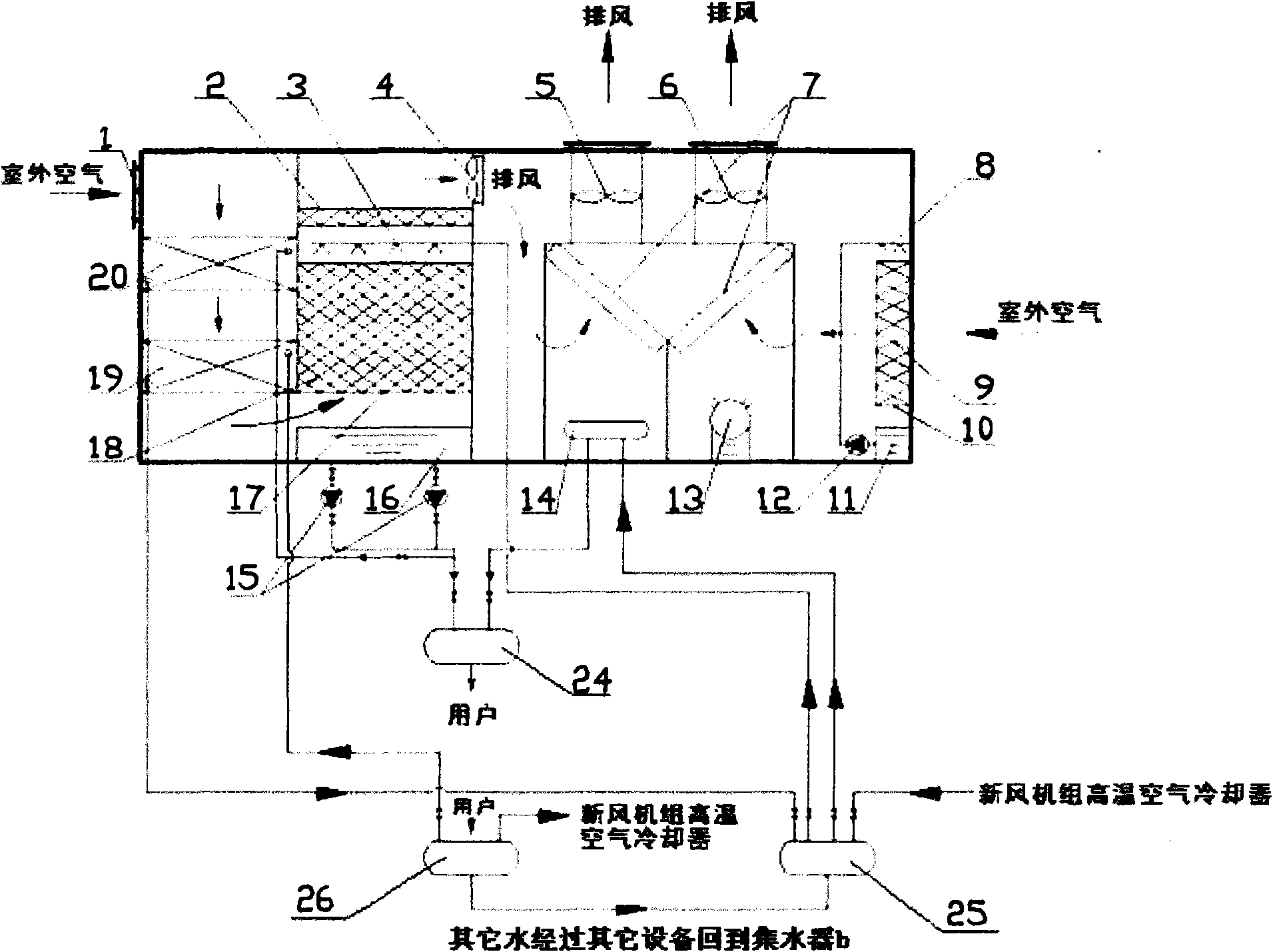

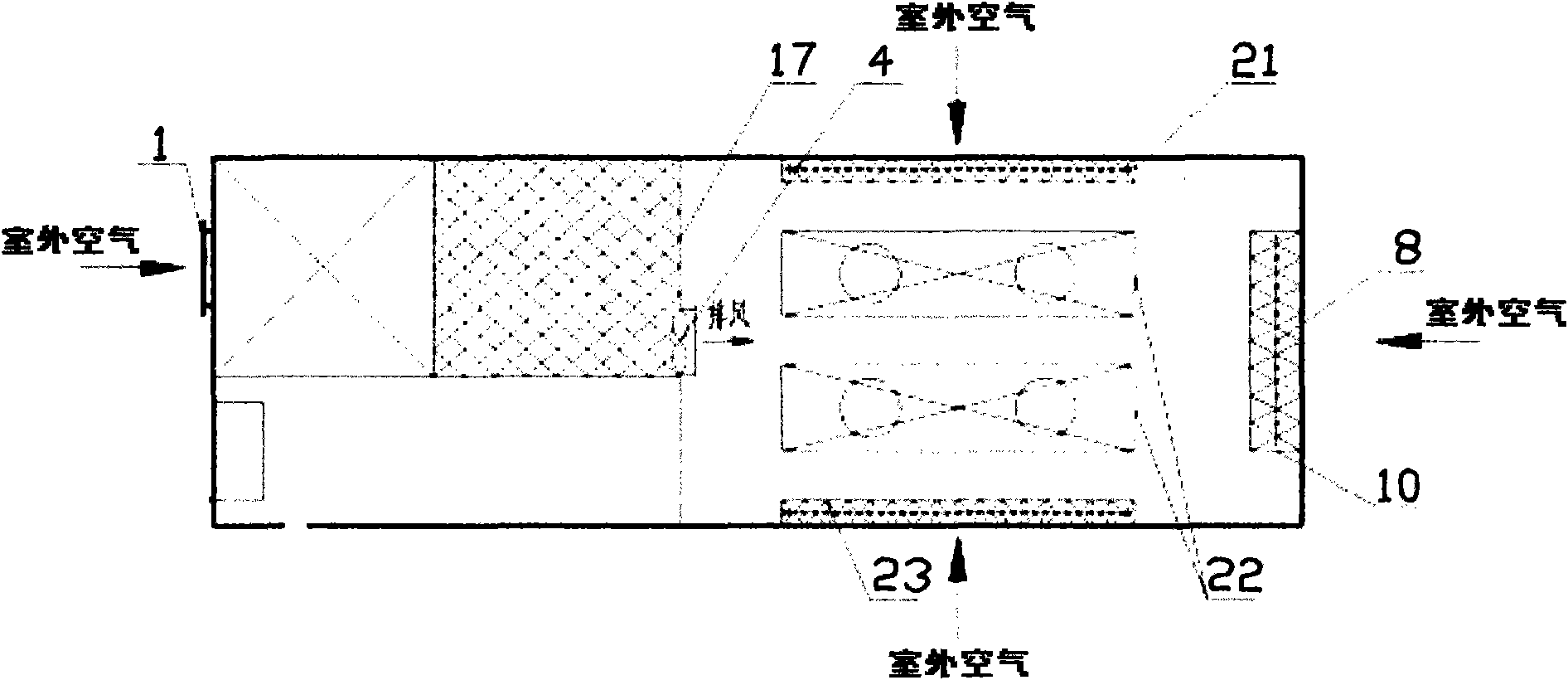

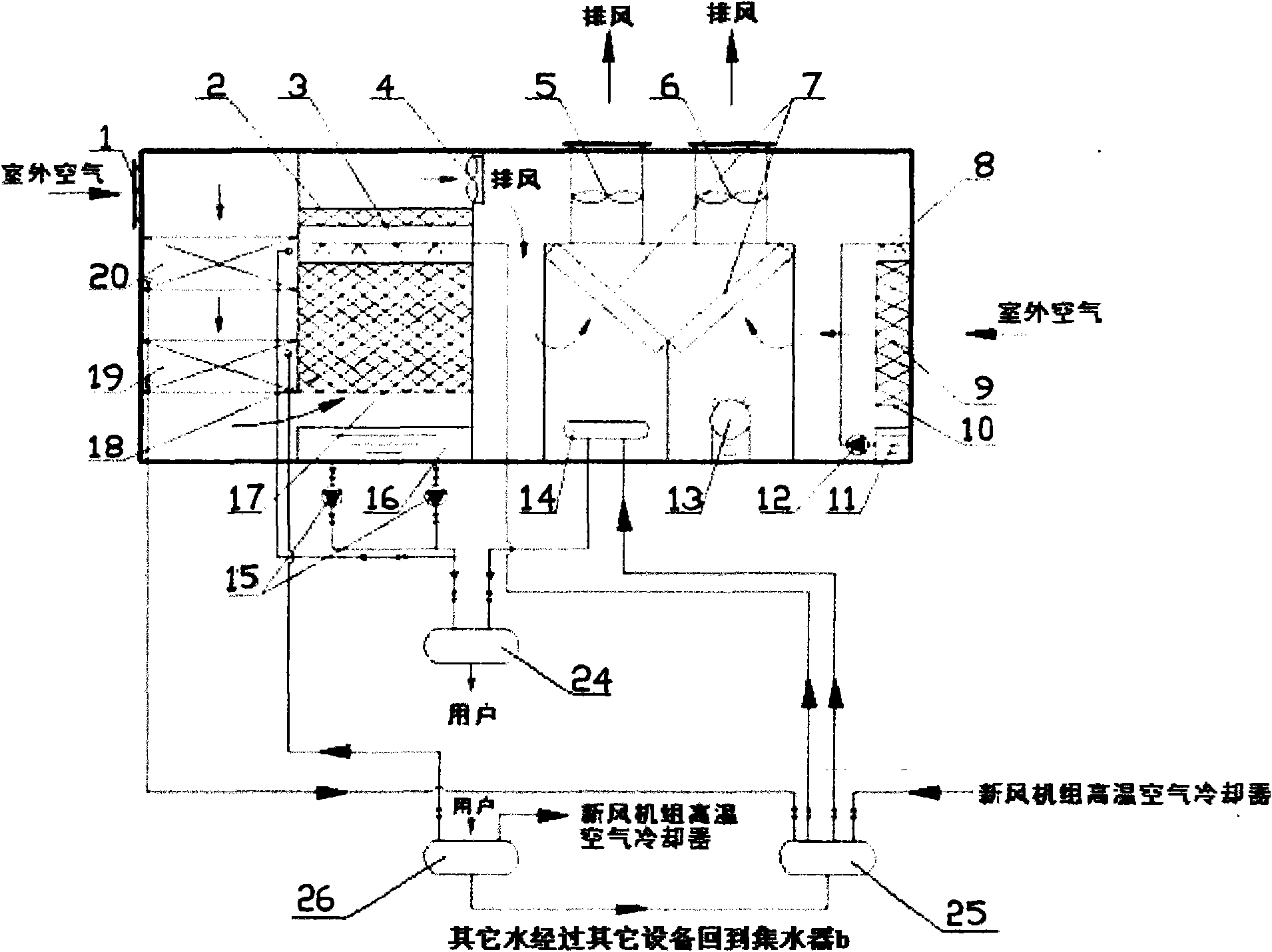

[0018] The composite cold and hot water unit of the present invention is composed of an evaporative water chiller, an air-cooled heat pump cold and hot water unit and a direct evaporative cooler. figure 1 , figure 2 It is an implementation of arranging the evaporative chiller, air-cooled heat pump cold and hot water unit and three direct evaporative coolers in the same cabinet, showing the evaporative chiller, air-cooled heat pump cold and hot water unit and three direct evaporative The relative position of the cooler.

[0019] The evaporative chiller includes a high temperature cold water air cooler 20 and a low temperature cold water air cooler 19 connected in parallel. The high temperature cold water air cooler 20 is provided with an air inlet 1 and also includes a direct evaporative cooler a17 and a direct evaporative cooler a17 above Set the water baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com