New four-point contact ball bearing

A four-point contact, ball bearing technology, used in ball bearings, bearing components, shafts and bearings, etc., can solve the problems of low axial bearing capacity and reliability, prevent cage deformation, and increase axial bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

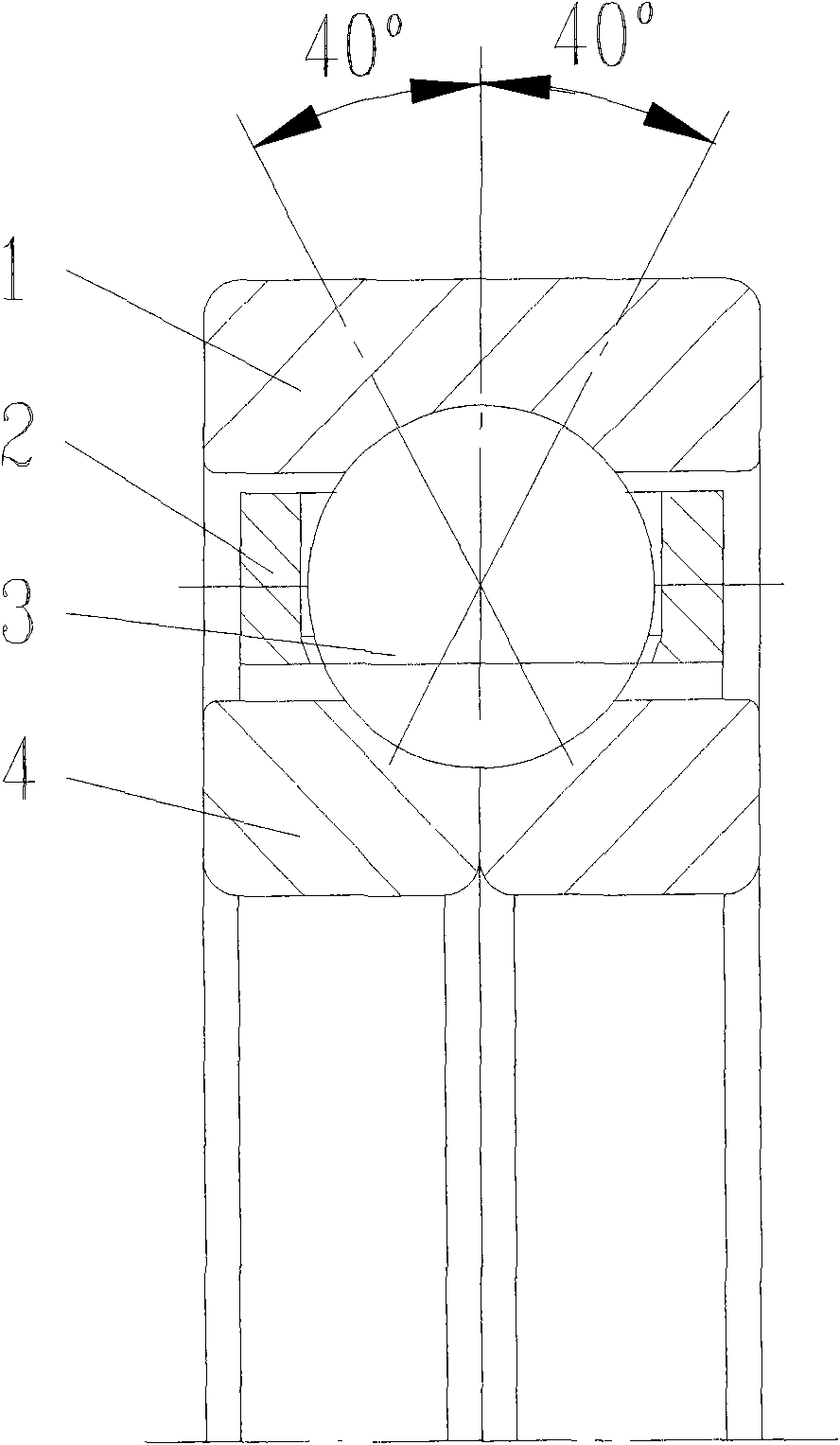

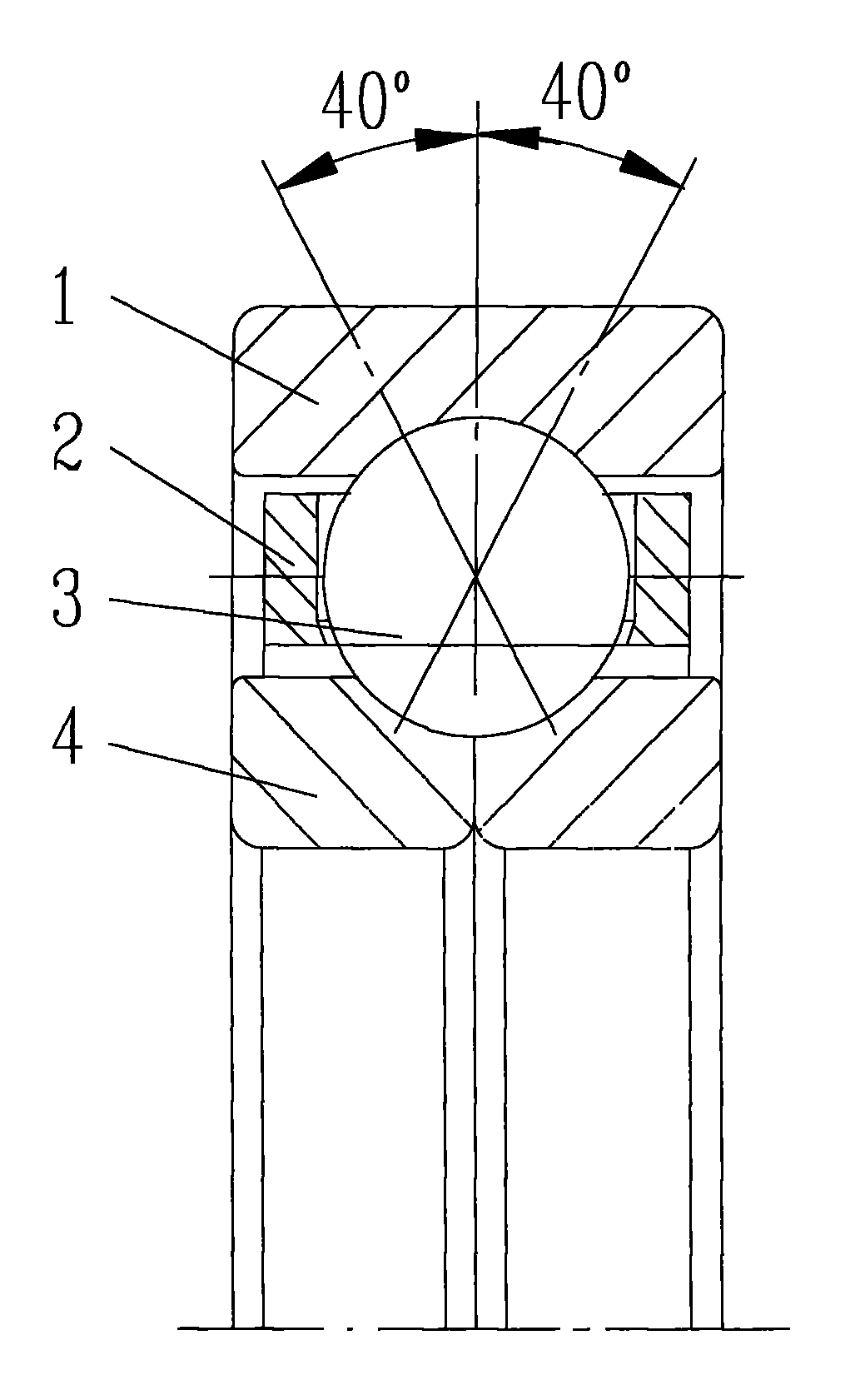

[0009] Such as figure 1 As shown, the present invention includes an outer ring 1, an inner ring 2, a steel ball 3 and a cage 4, and the cage 4 is an integrated self-locking cage, and the steel ball 3 can be effectively locked through the inner lock of the cage, effectively To prevent the deformation of the cage caused by gouging and the phenomenon of ball drop due to uneven locking. The contact angle of the bearing is increased from the traditional 35 degrees to 40 degrees, which increases the axial bearing capacity of the bearing and meets the working conditions of the bearing used in the subway light rail gearbox.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com