Rigid-flexible coupling joint based on complex rolling contact curved surface

A rolling contact, rigid-flexible coupling technology, applied in the field of medical robots, can solve the problems of difficulty in establishing an accurate rigid-flexible coupling model, difficult miniaturization processing, and complex joint structure of continuum robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

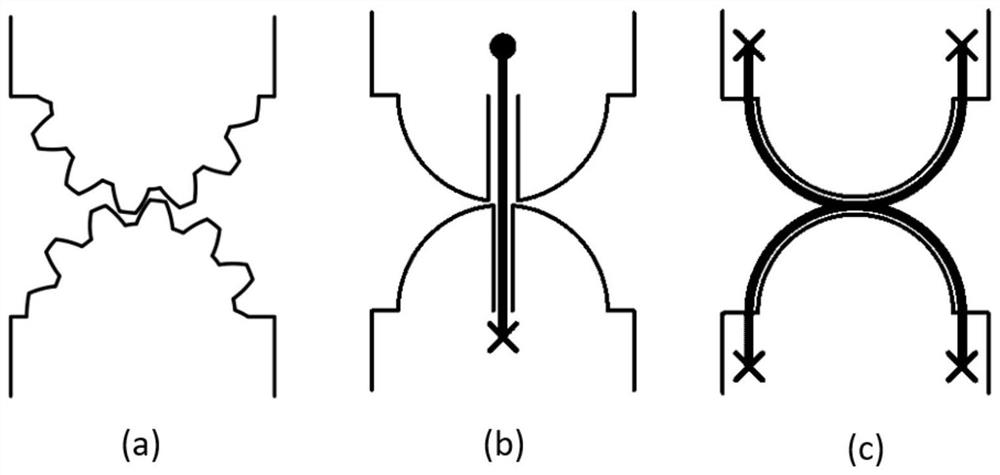

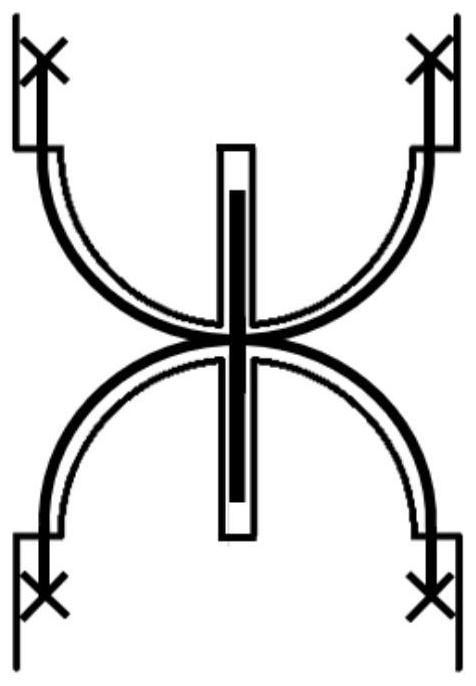

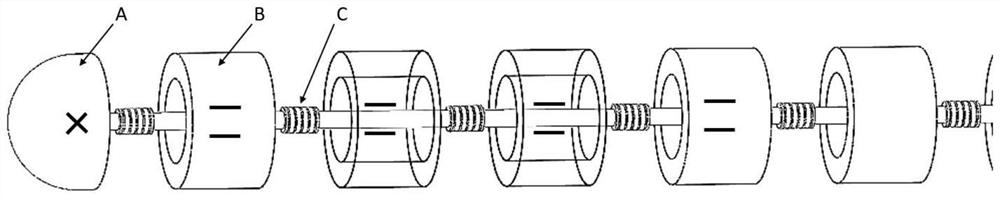

[0026] The invention discloses a rigid-flexible coupling joint based on a complex rolling contact surface. The overall structure of the rigid-flexible coupling joint can be found in Figure 5 , including two rolling contact joint main bodies 1 with the same configuration, four wires 4 and two flexible rods 2 fixed on the outside of the two rolling contact joint main bodies 1 through connecting bodies 3 . Wherein, each rolling contact joint body 1 is a rigid structure including a complex curved surface 101, specifically including four lugs 102, and the connecting body 3 is fixed on the outside of the four lugs 102; the four lugs 102 form two groups, the same group The two lugs in the structure are parallel to each other, and the lugs in different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com