Method for preparing poly-aluminum ferric chloride sulfate and product thereof

A technology for polymerizing bis-aluminum iron and bis-aluminum iron, which is applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of high cost, complicated process, and low basicity of products, and achieve low cost, The preparation process is simple and the effect of improving the basicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

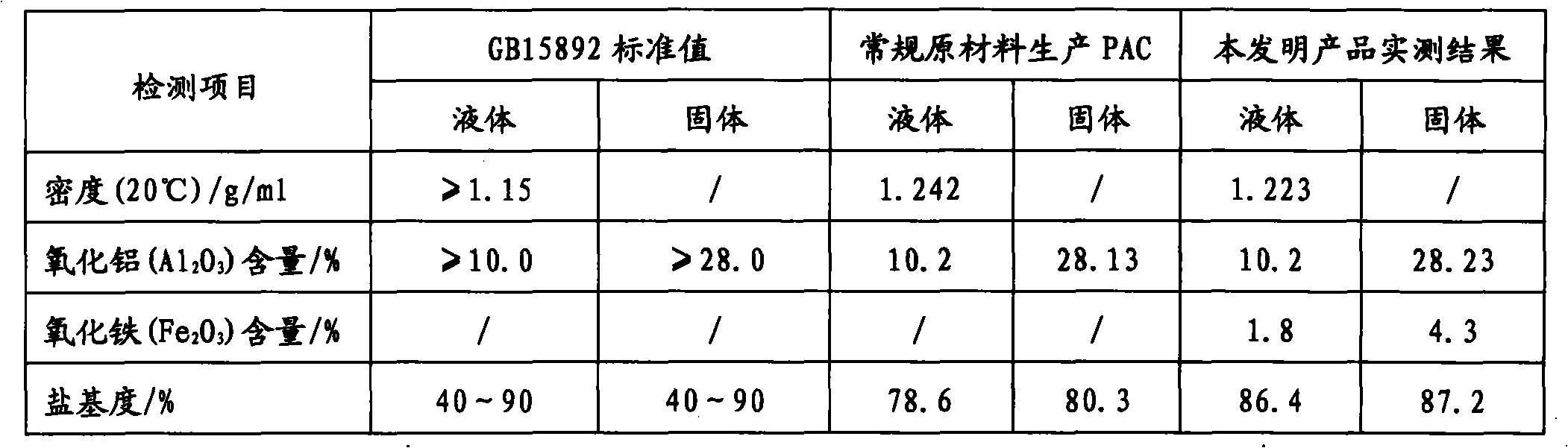

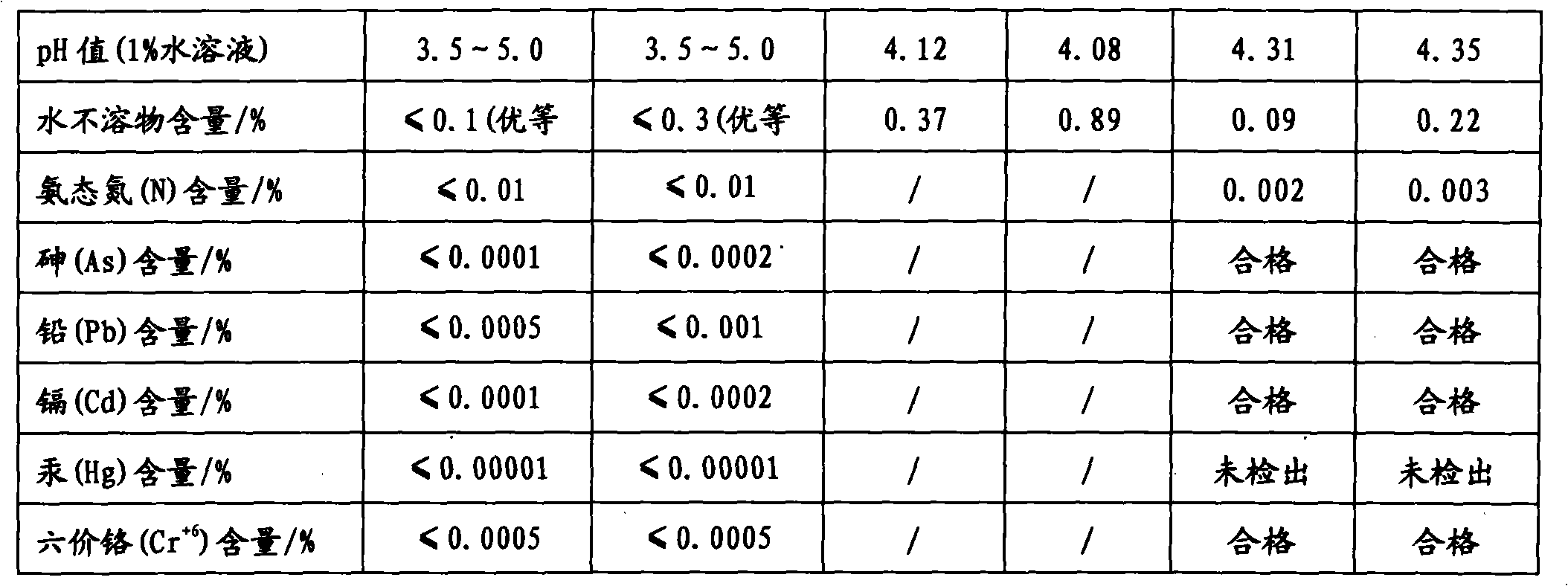

[0016] A kind of manufacture method of polyaluminum iron bis-acid of the present invention, the raw material that adopts and content are as follows:

[0017] 5-10 parts of 98% industrial sulfuric acid; 100-150 parts of industrial hydrochloric acid with a total acidity of 31%; 30-50 parts of iron-containing bauxite powder, which contains 40-45% of % iron oxide by mass fraction; 20-70 parts of calcium aluminate powder, wherein acid-soluble aluminum content is 50%, calcium oxide content is 28-31%; synergist, water glass or sodium aluminosilicate 3-5 parts, formulated 20-40 solution.

[0018] The preparation steps are as follows:

[0019] Step 1: First, add a certain amount of water into the enamel reaction kettle with a stirring device, start stirring, add hydrochloric acid and sulfuric acid in sequence according to the proportion, add iron-containing bauxite powder under normal pressure conditions, and heat up to 90 ~100°C, keep warm and react under normal pressure for 2~4h; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com