Suspension cushion assembly of powertrain system of automobile

A technology for automotive powertrain and suspension cushions, applied in the direction of power devices, vehicle components, jet propulsion devices, etc., can solve the problems of reducing or offsetting the inherent resonance excitation of the power system, so as to improve NVH performance and improve The effect of dynamic stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

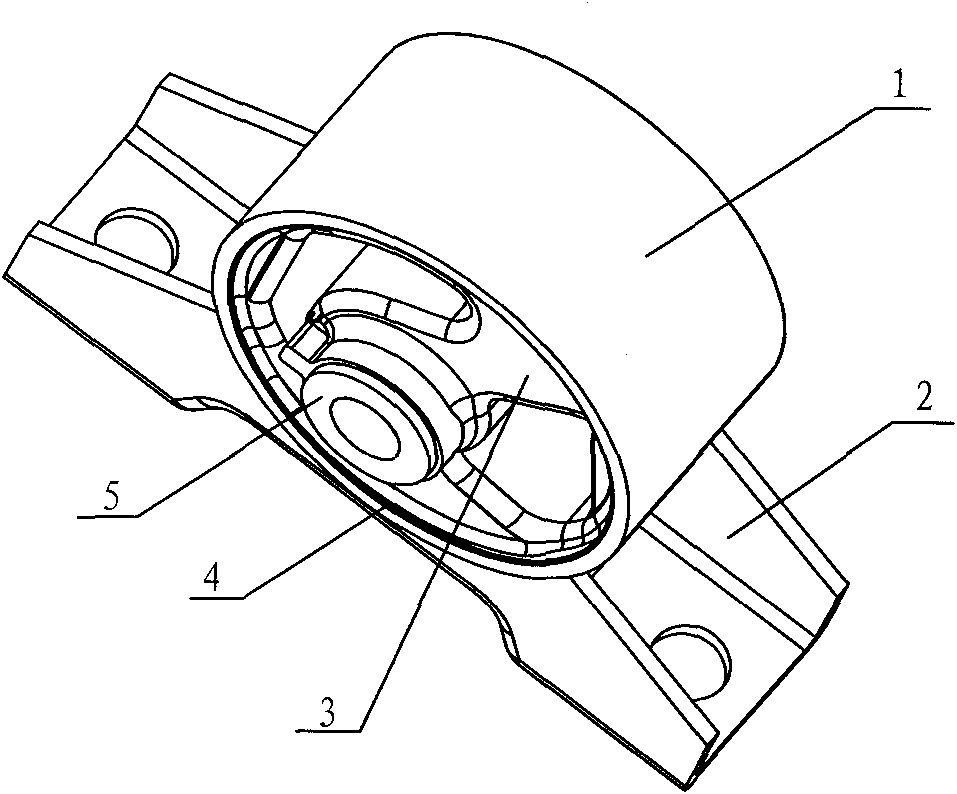

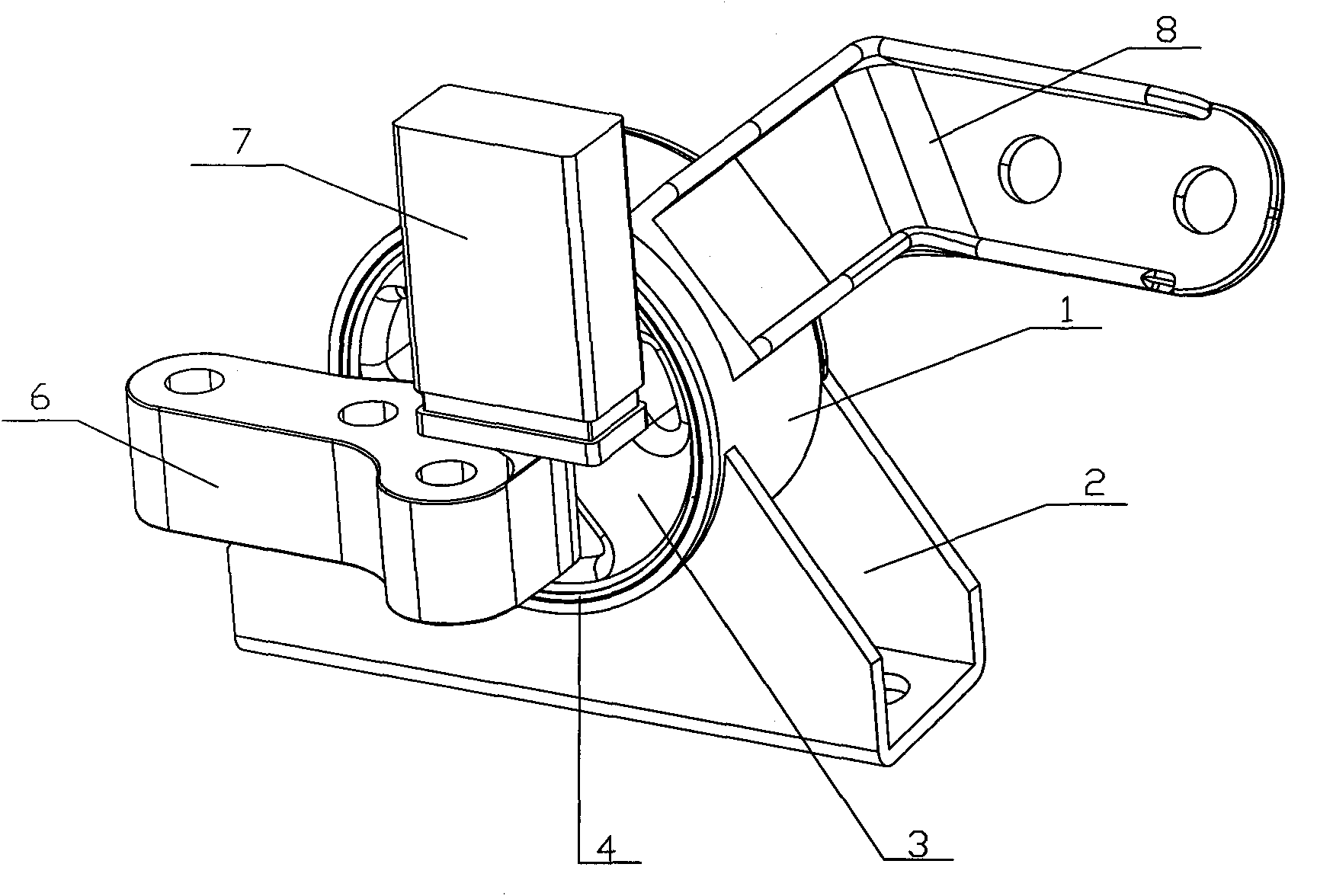

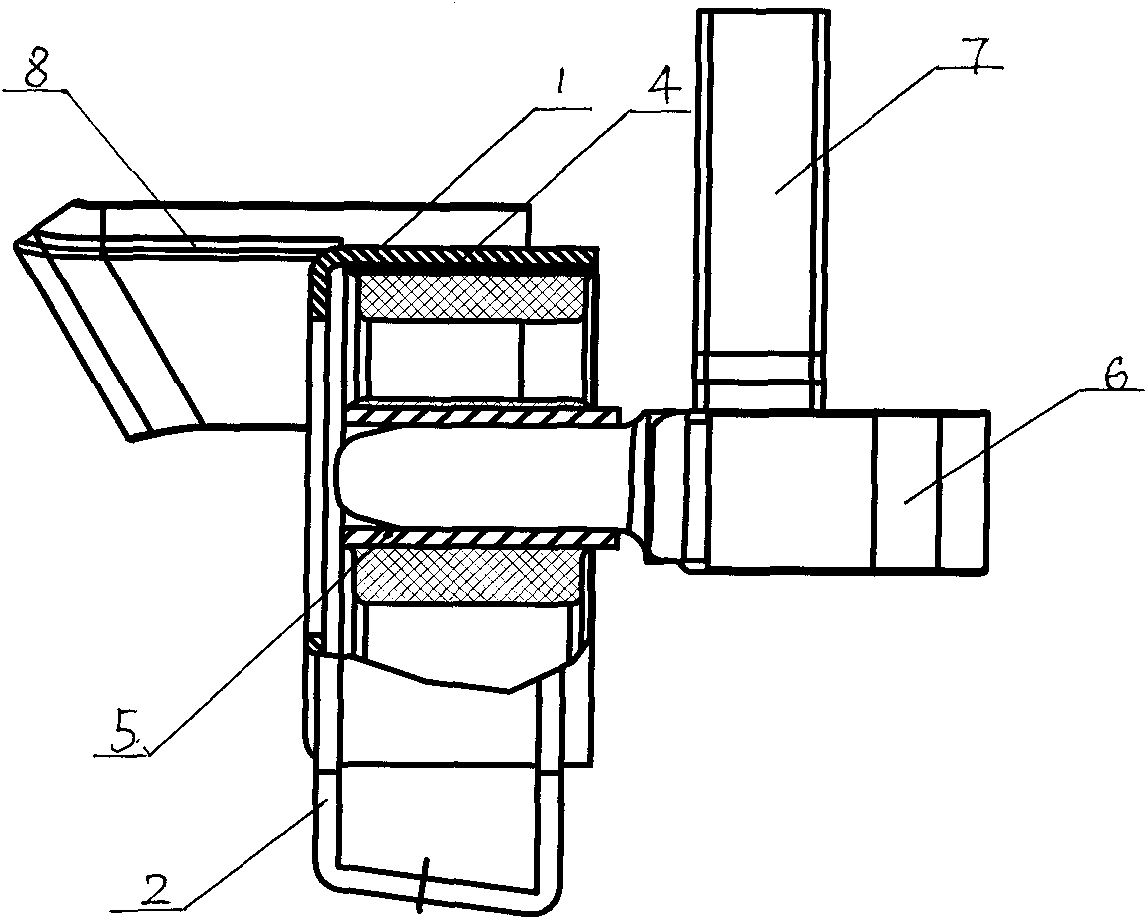

[0017] as attached figure 2 , image 3 , Figure 4 As shown, the suspension cushion assembly has a rubber bushing 3, a metal skeleton, a mandrel 6, a dynamic shock absorber 7, and a reinforced metal L-shaped brace 8. The metal skeleton is welded by the cylindrical skeleton 1 and the connecting bracket 2, and the reinforced metal L-shaped bracing 8 is directly welded to the top of the cylindrical skeleton 1 suspending the metal skeleton, and the closer to the middle position the better. The cylindrical skeleton 1 is used for installing the rubber bushing 3, and the connecting bracket 2 and the L-shaped brace 8 are used for connecting the vehicle body. The outer sleeve 4 of the rubber bushing 3 is in interference fit with the inner wall of the round frame 1 of the metal frame. The protruding shaft of the mandrel 6 is inserted into the inner sleeve 5 of the rubber b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com