Filter panel laminates and diaphragm filter panel

A filter plate and membrane technology, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of poor filtration effect, filter stoppage, etc., and achieve the effect of avoiding inadvertent tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

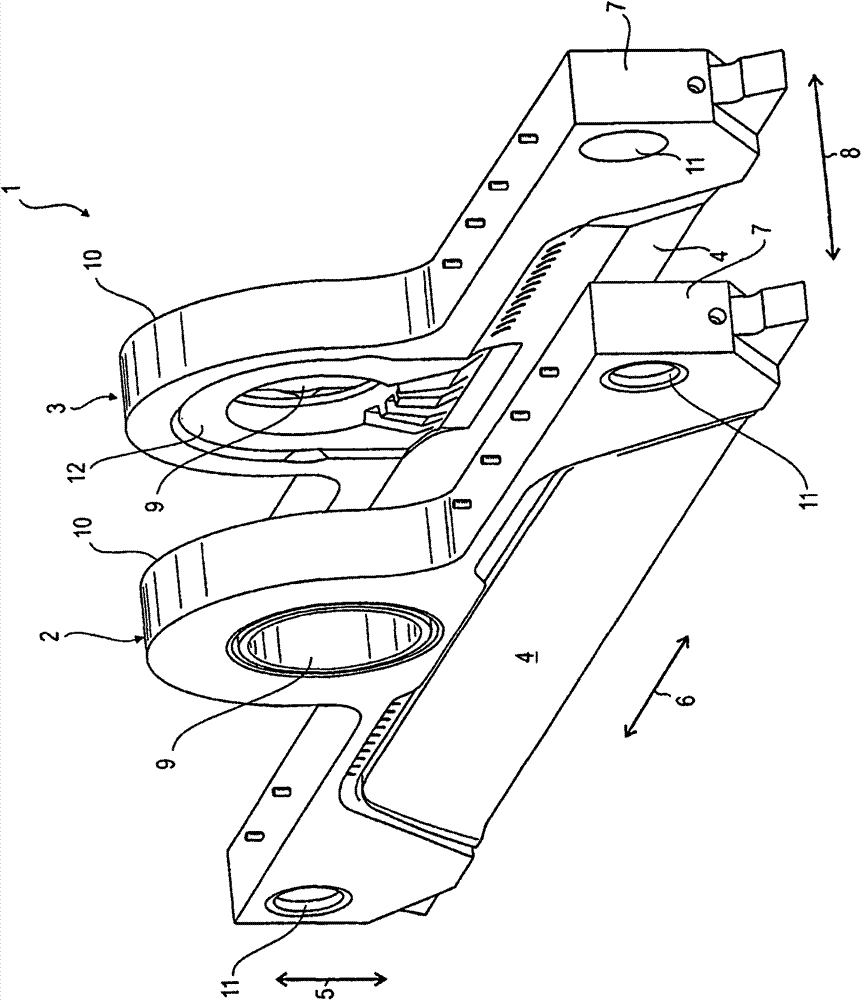

[0068] Such as figure 1 As shown, the filter plate pack 1 includes a membrane filter plate 2 and a cavity filter plate 3 as components of a membrane filter press (not shown in the figure). Each filter plate 2, 3 has an inner plate body and a filter plate surface, namely the filter surfaces 4 on both sides. The filter surface 4 is surrounded on the edge side both in the vertical direction 5 and in the horizontal direction 6 by a filter plate edge, ie a sealing edge 7 , which is thickened relative to the filter surface 4 . In other words, the sealing edge 7 surrounds the filter surface 4 in the vertical direction 5 and in the horizontal direction 6 . exist figure 1 Only the upper parts of the two filter plates 2, 3 are shown in the figure. Both the sealing edge 7 and the filter surface 4 are conceived as extending downward in the vertical direction 5 . The sealing edge 7 protrudes clearly on both sides relative to the filter surface 4 in the installation direction 8 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com