Hose joint, hose pipeline and method for producing hose joint

A technology for hose joints and hoses, applied in the directions of pipes/pipe joints/pipes, hose connection devices, hoses, etc., can solve the problems of increased hose pipeline structure and manufacturing cost, and avoid unfavorable reductions. , The effect of accurate installation and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

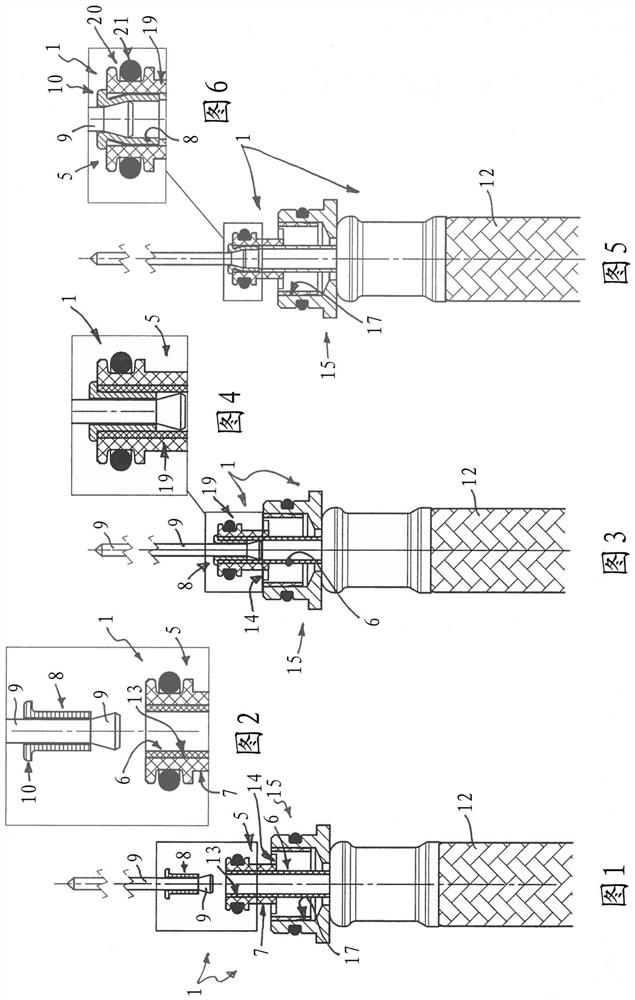

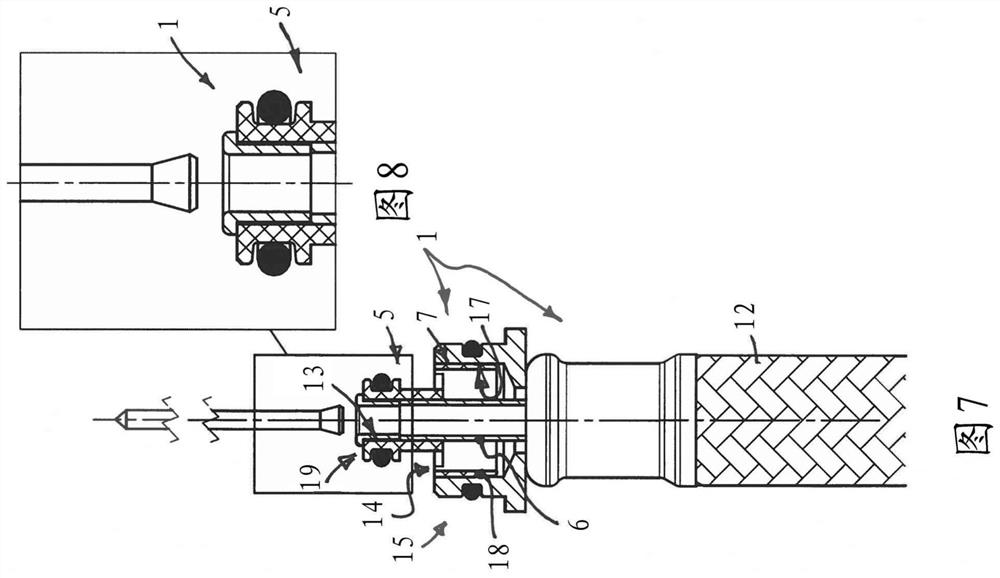

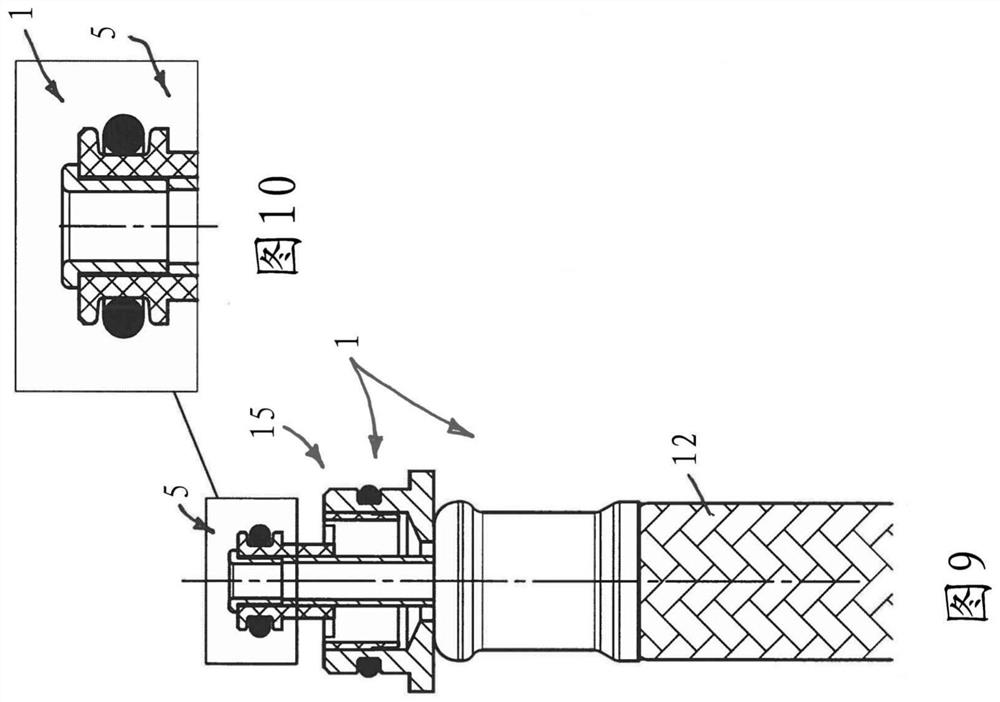

[0066] exist Figure 9 , 10 ; 12, 13; 20, 21 and 28, 29 show flexible hose lines in different embodiments 1, 2, 3 and 4, said hose line in its hose end region at least One has a hose connection 5 on it. exist Figures 1 to 8 , 14 to 19 and 22 to 27 show production steps according to various exemplary embodiments, which are provided for producing the hose lines 1 , 3 and 4 and for installing the at least one hose connection 5 .

[0067] The hose lines 1 , 2 , 3 and 4 have at least one flexible hose 6 with a hose connection 5 on at least one of its two hose end regions. By means of the hose connection 5 , the fluid guide can adjoin a further line section on the inflow side or the outflow side and continue the fluid guide.

[0068] For this purpose, the hose connection 5 has an outer part 7 which surrounds the hose end region of the at least one hose 6 and an inner part 8 which can be introduced into the inner hose cross-section of the hose 6 . In this case, the inner part 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com