Bouncing-prevention damping spacing rod

A spacer and anti-galling technology, applied in the direction of the device to maintain the distance between parallel conductors, can solve the problems of increased probability of galloping of split conductors, uneven icing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

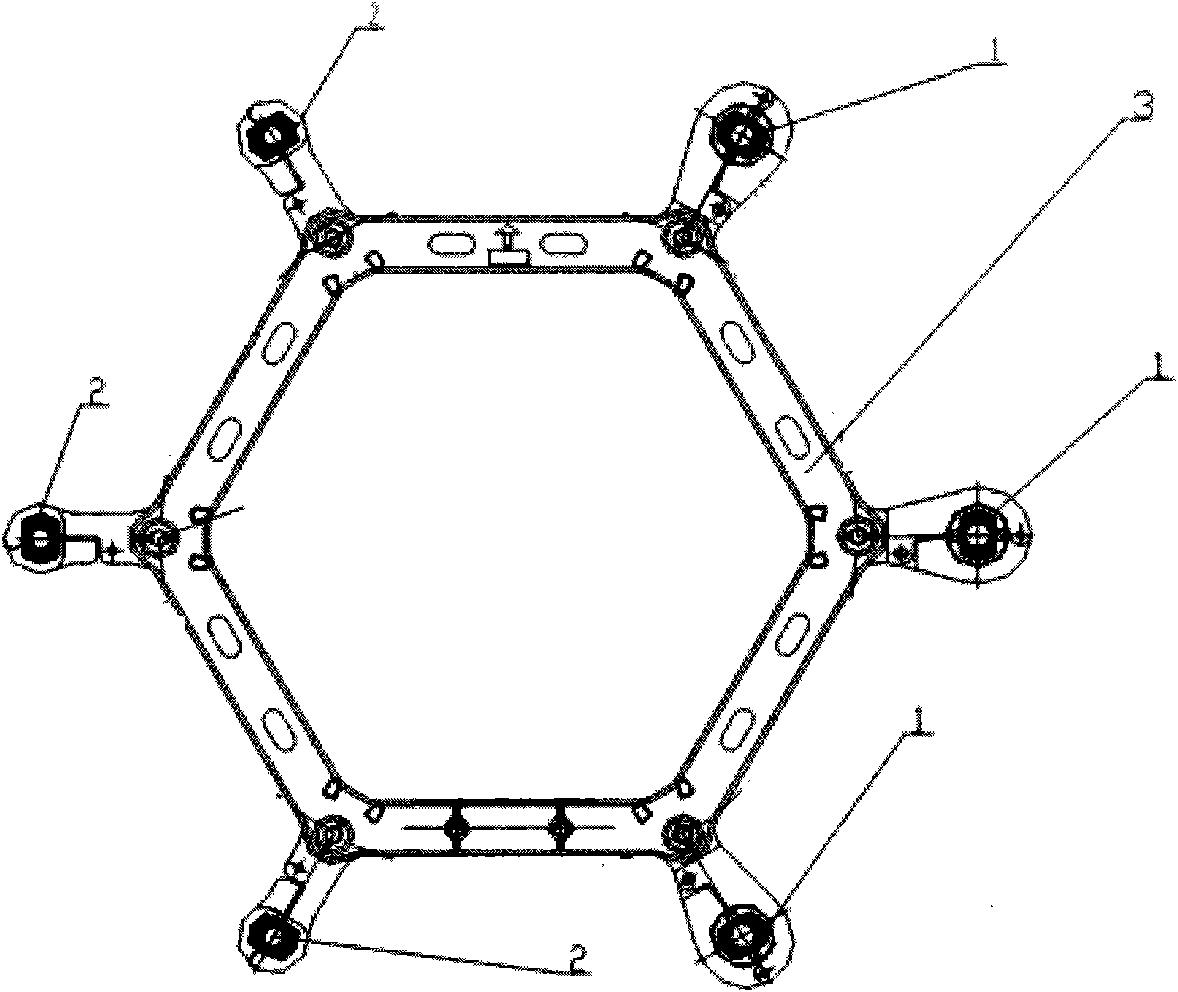

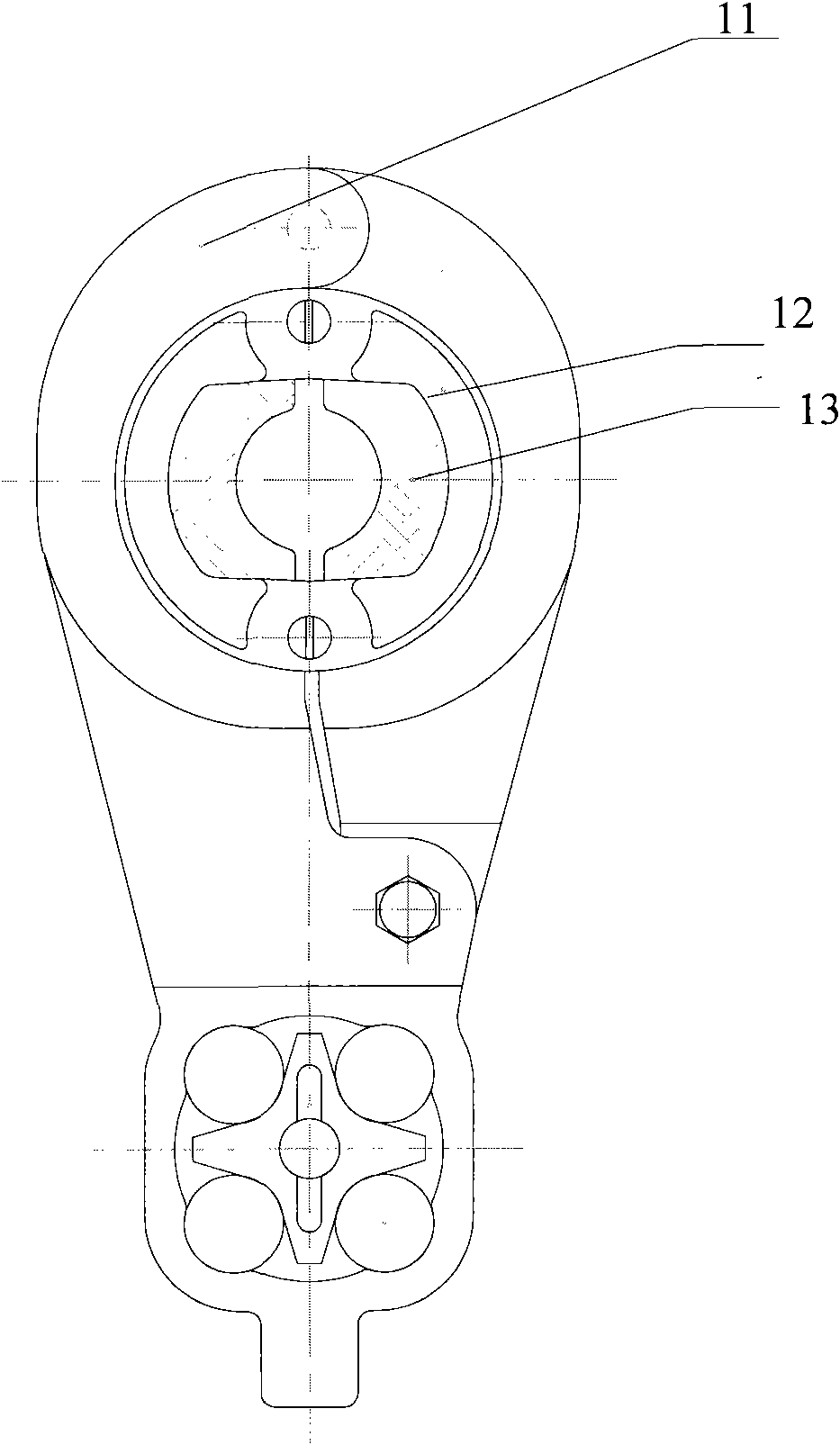

[0028] The anti-galling damping spacer provided in the present invention includes: a rotatable wire clamp 1 , an ordinary wire clamp 2 , and a double-plate body frame 3 . The device includes three rotatable wire clamps 1 and three common wire clamps 2, which are evenly distributed on the six ends of the hexagonal body frame 3. The rotatable line clamp 1 is located on the hexagonal end point on the windward side, and the common line clamp 2 is located on the hexagonal end point on the leeward side. The connection part between the rotatable wire clip 1 and the body frame 3 is the same as the connection part between the common wire clip 2 and the body frame 3 .

[0029] Compared with the existing spacer, the anti-galling damping spacer provided by the present invention does not change the connection form between the wire clip and the body frame, but realizes the rotation of the wire through the rotatable wire clip 1 . Therefore, no special tools are required during installation,...

Embodiment 2

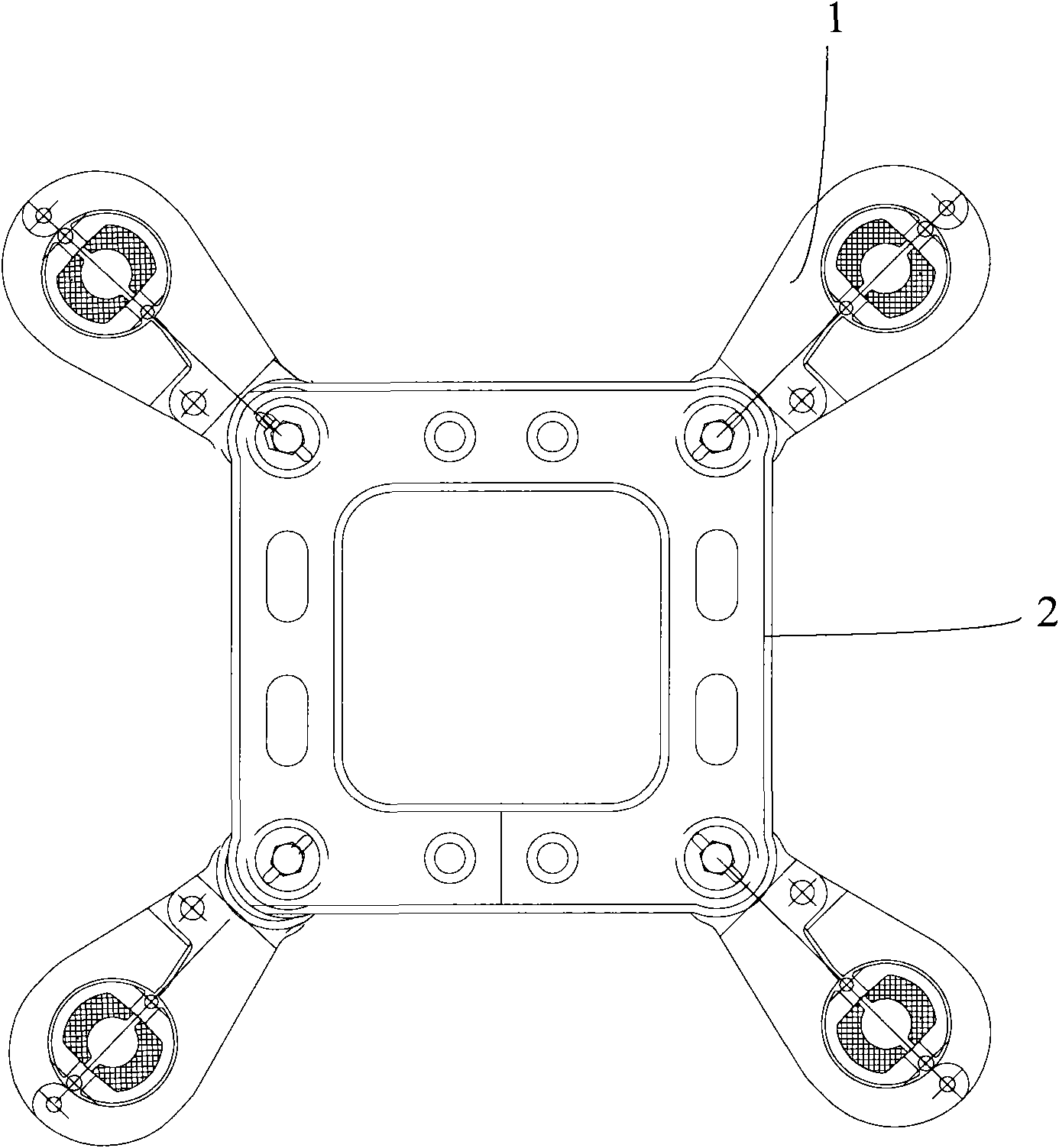

[0034] The anti-flapping damping spacer provided in this embodiment includes: a rotatable wire clamp 1 and a double-plate body frame 2 . The device includes four rotatable clamps 1, which are evenly distributed on the four ends of the regular quadrilateral body frame 2.

[0035] The structure of the rotatable wire clamp in this embodiment is the same as that in Embodiment 1, and will not be described here again. Compared with the first embodiment, all the clamps in this embodiment are rotatable clamps, which can better suppress the occurrence of galloping.

[0036] It should be noted that this embodiment does not limit the scope of application of the anti-galling damping spacer rods disclosed in the present invention, and any two-split or above phase-split wires can be used. Secondly, this embodiment also does not limit the number and installation positions of the ordinary wire clips and the rotatable wire clips in the actual application process, as long as the installed spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com