Cleaning and drying integrated equipment for manufacturing copper clad aluminum busbars

A technology of drying equipment and copper-clad aluminum row, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of inability to guarantee the quality of copper-clad aluminum row, secondary oxidation pollution, energy waste, etc. Achieve the effects of avoiding secondary oxidation and pollution, saving energy, and shortening the material circulation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

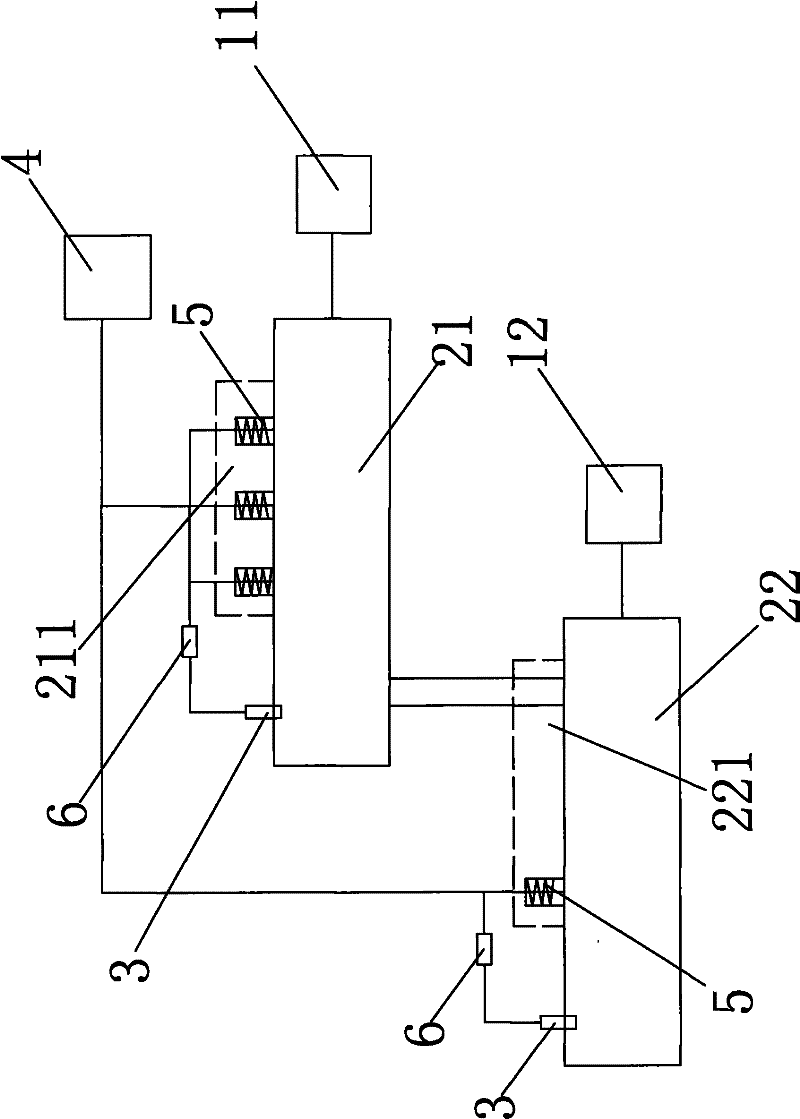

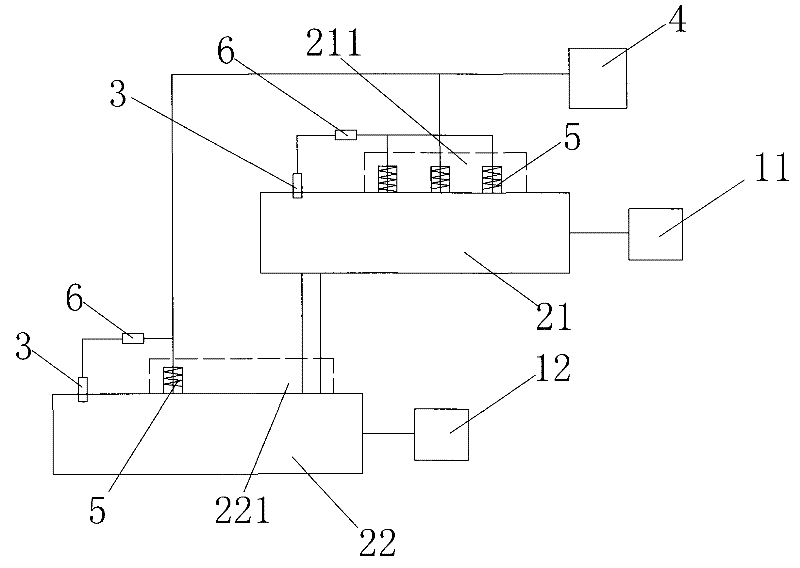

[0011] like figure 1 It is an embodiment of the cleaning and drying integrated equipment for the manufacture of copper-clad aluminum bars of the present invention. The equipment includes cleaning equipment, drying equipment and air supply equipment 4. The cleaning equipment includes cleaning equipment one 11 and cleaning equipment two 12. Drying equipment comprises drying equipment one 21 and drying equipment two 22, cleaning equipment one 11 is connected with drying equipment one 21 by conveyor belt, cleaning equipment two 12 is connected with drying equipment two 22 by conveyor belt, and the air outlet 211 on drying equipment one 21 It is connected with the air inlet two 221 on the drying equipment two 22 through the hot air pipeline, and the air supply equipment 4 is respectively connected with the air inlet one 211 on the drying equipment one 21 and the air inlet two 221 on the drying equipment two 22 through the ventilation duct. Air inlet one 211 and air inlet two 221 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap