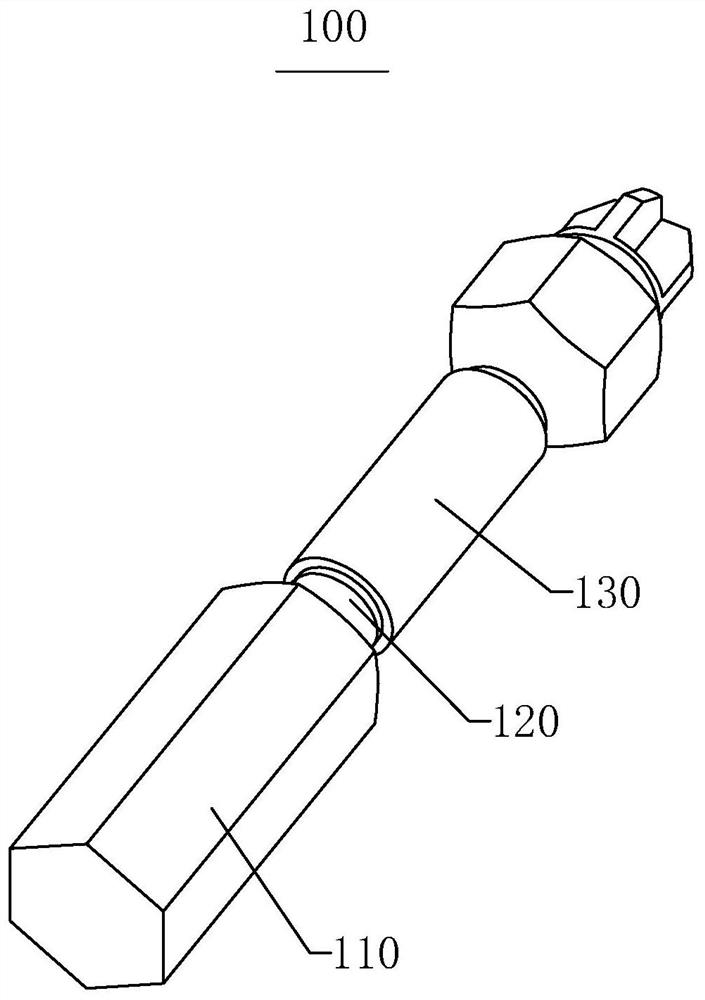

Screwdriver head heat shrink pipe sleeving production line

A heat-shrinkable tube and production line technology, applied in conveyor objects, conveyors, metal processing, etc., can solve the problems of low production efficiency, large workload, long circulation cycle, etc., to reduce workload, improve applicability, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be clearly and completely described below in conjunction with the embodiments.

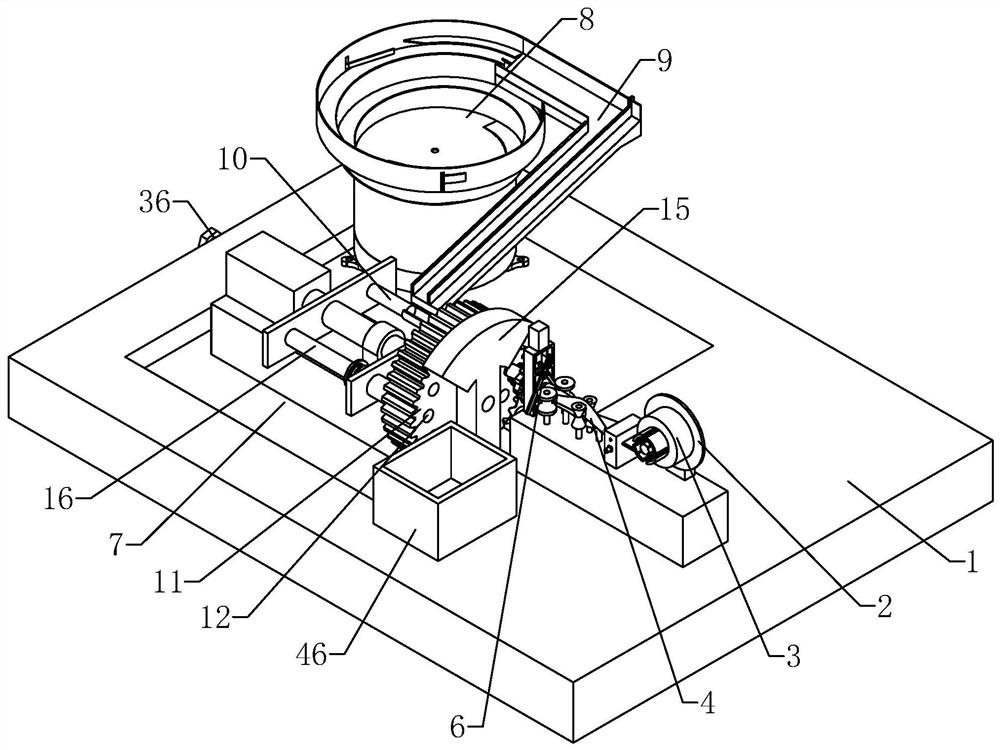

[0042] See attached figure 2 , a batch head heat-shrinkable tube socket production line, including a frame 1, the frame 1 can be a cuboid frame structure, and the frame 1 is sequentially provided with an unwinding mechanism, a casing opening and cutting mechanism, a batch feeding mechanism, Bit socket mechanism, heat shrink mechanism and bit unloading mechanism.

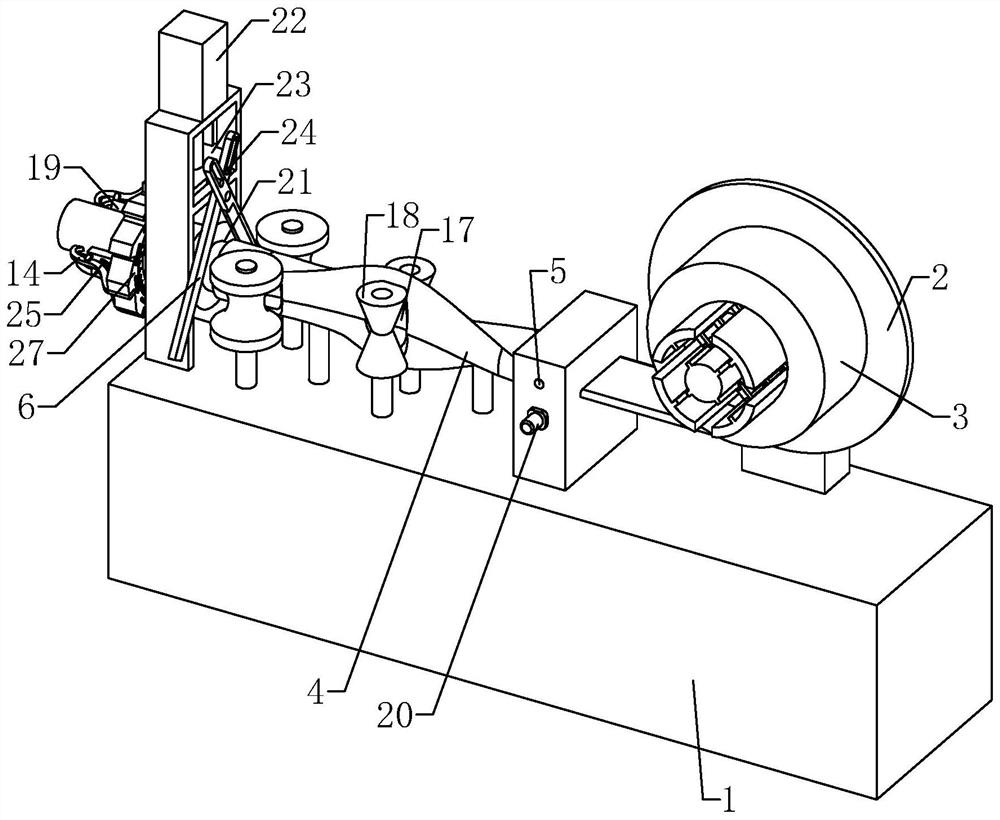

[0043] The unwinding mechanism includes an unwinding frame 2 rotatably arranged on one side of the frame 1 in the longitudinal direction, and a heat-shrinkable coil 3 is fixedly arranged on the unwinding frame 2 . The casing opening and cutting mechanism includes a material guide tube 4 arranged on the frame 1 for opening the heat-shrinkable coiled material 3, and two conveying rollers 5 ( image 3 Shown in), two cutting knives 6 are movably arranged on the material guide pipe 4.

[0044] The batch f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap