Dual-tower argon producing system and process thereof

A process and system connection technology, which is applied in the field of air separation, can solve the problems of large investment, difficulty, and complex three-tower argon production process, and achieve the effects of saving investment, simple control, and reducing liquid pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

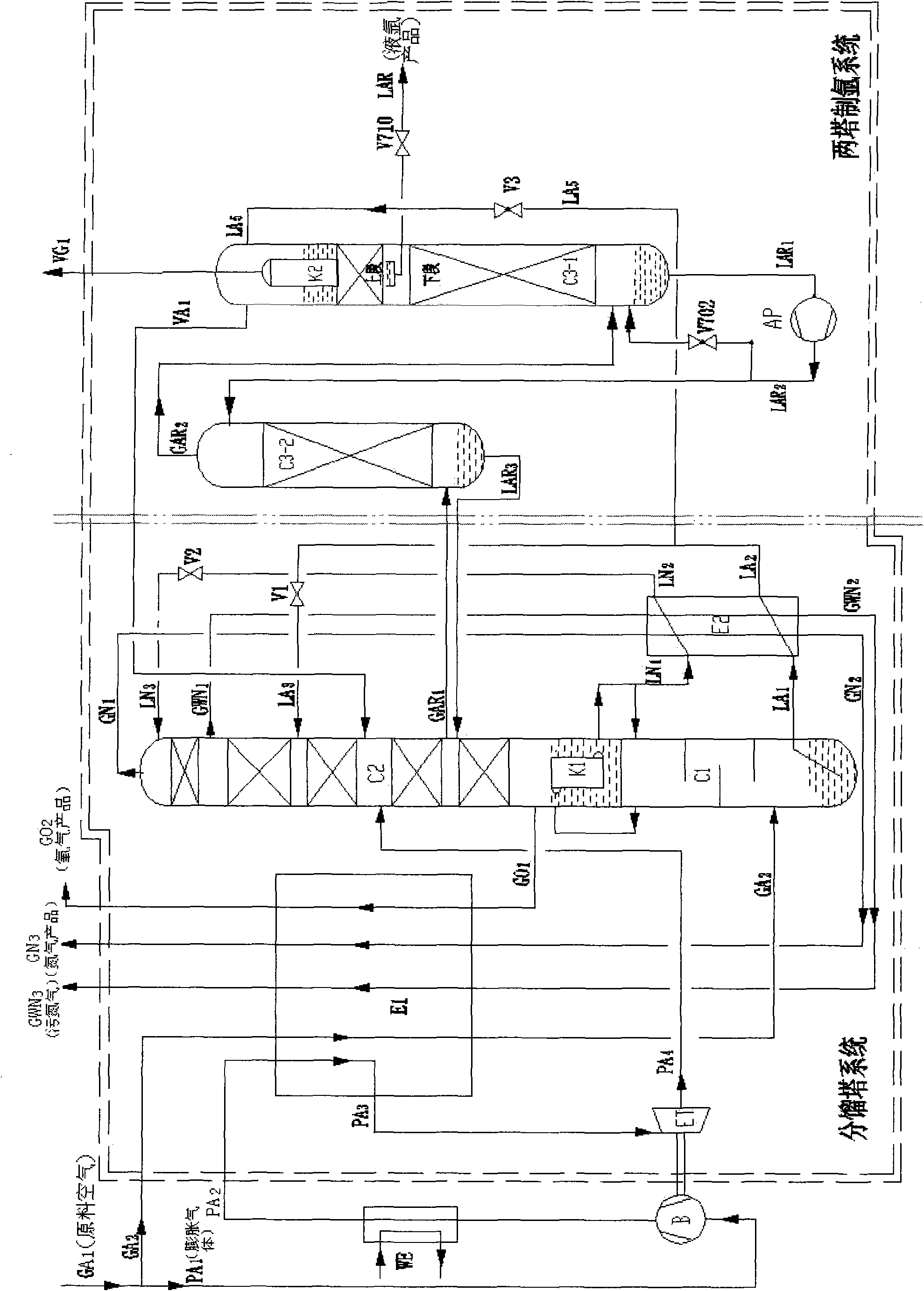

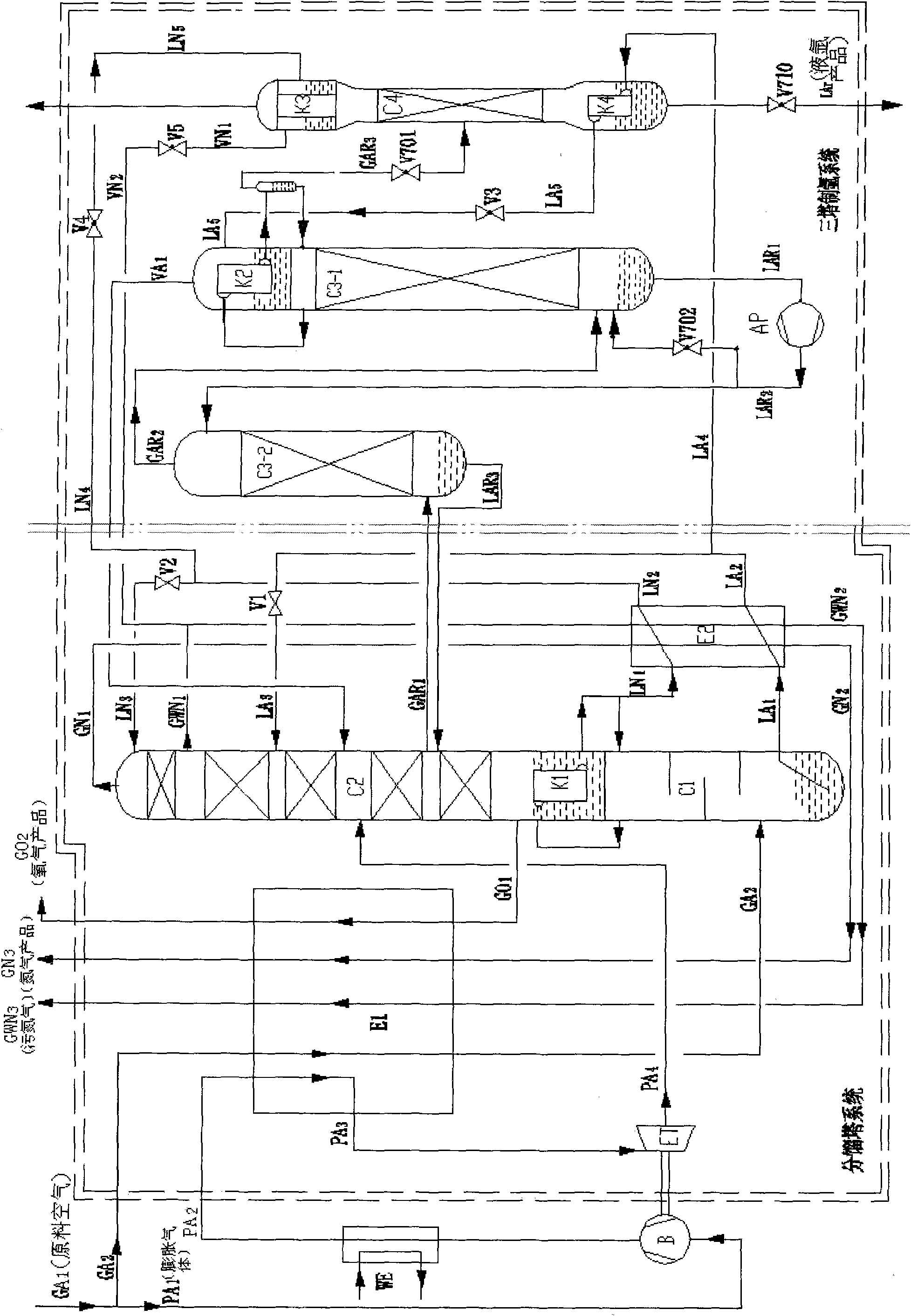

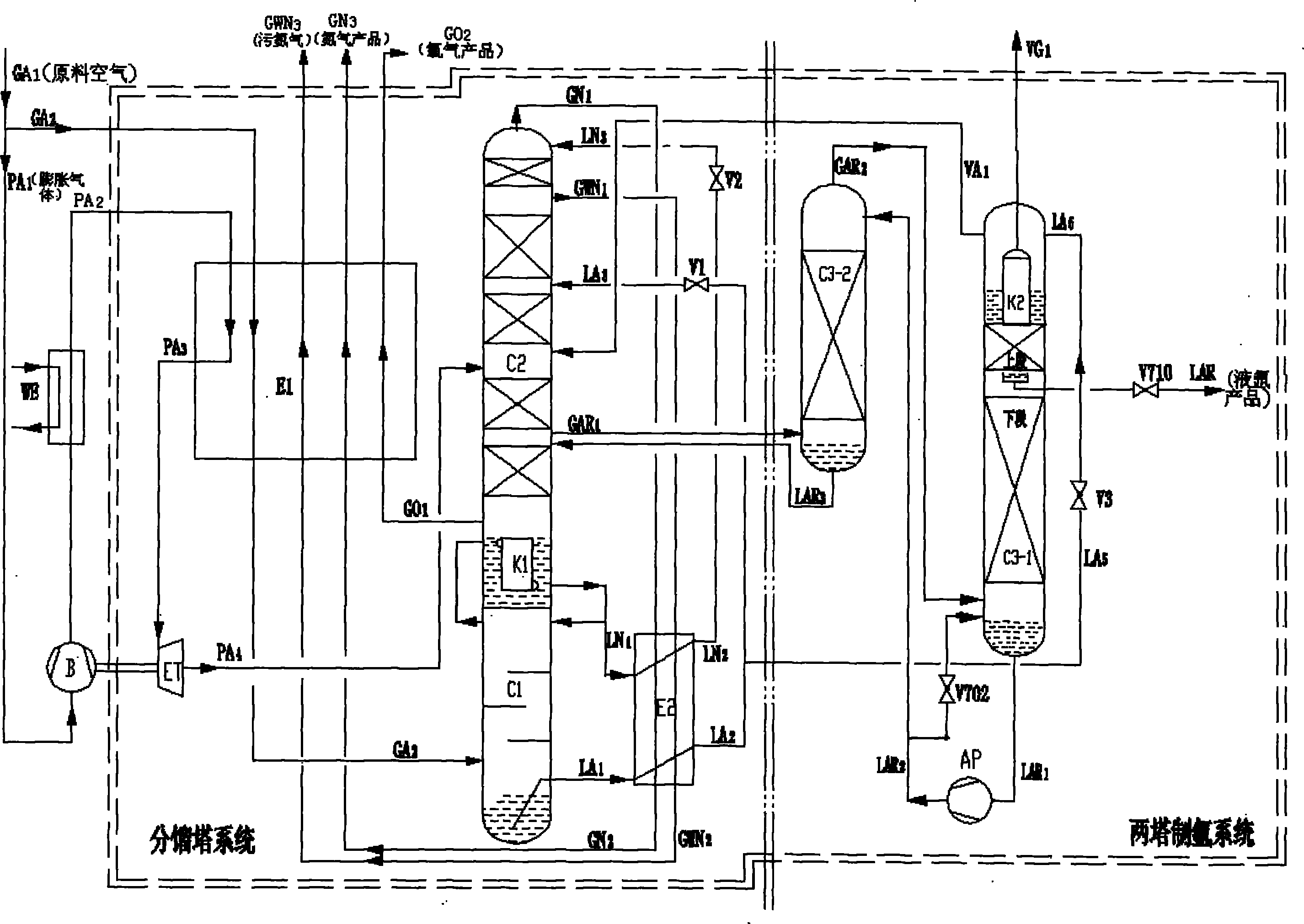

[0026] Such as figure 1 Shown, the present invention comprises air fractionation tower system and the argon making system that is connected with air fractionation tower system, and described argon making system is made of crude argon tower I (C3-1), thick argon tower II (C3-2), Condenser (K2) and circulating liquid argon pump (AP).

[0027] The crude argon column I is an integration of the crude argon column I (C3-1) and the refined argon column.

[0028] The crude argon tower I (C3-1) is divided into an upper section and a lower section, the upper section and the lower section of the crude argon tower I (C3-1) are packed towers, and the packed tower is composed of packing components and packing.

[0029] The condenser (K2) adopts a plate-fin structure, and the condenser (K2) is divided into room I and room II, wherein room I uses liquid air as a medium, and room II uses liquid argon as a working medium.

[0030] A two-tower argon production process has the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com