Hydraulic oil pump

An oil pump and hydraulic technology, applied in the field of hydraulic driven oil production equipment, can solve the problems of disconnection of sucker rods, oil pipe leakage detection, shortening the pump cycle, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

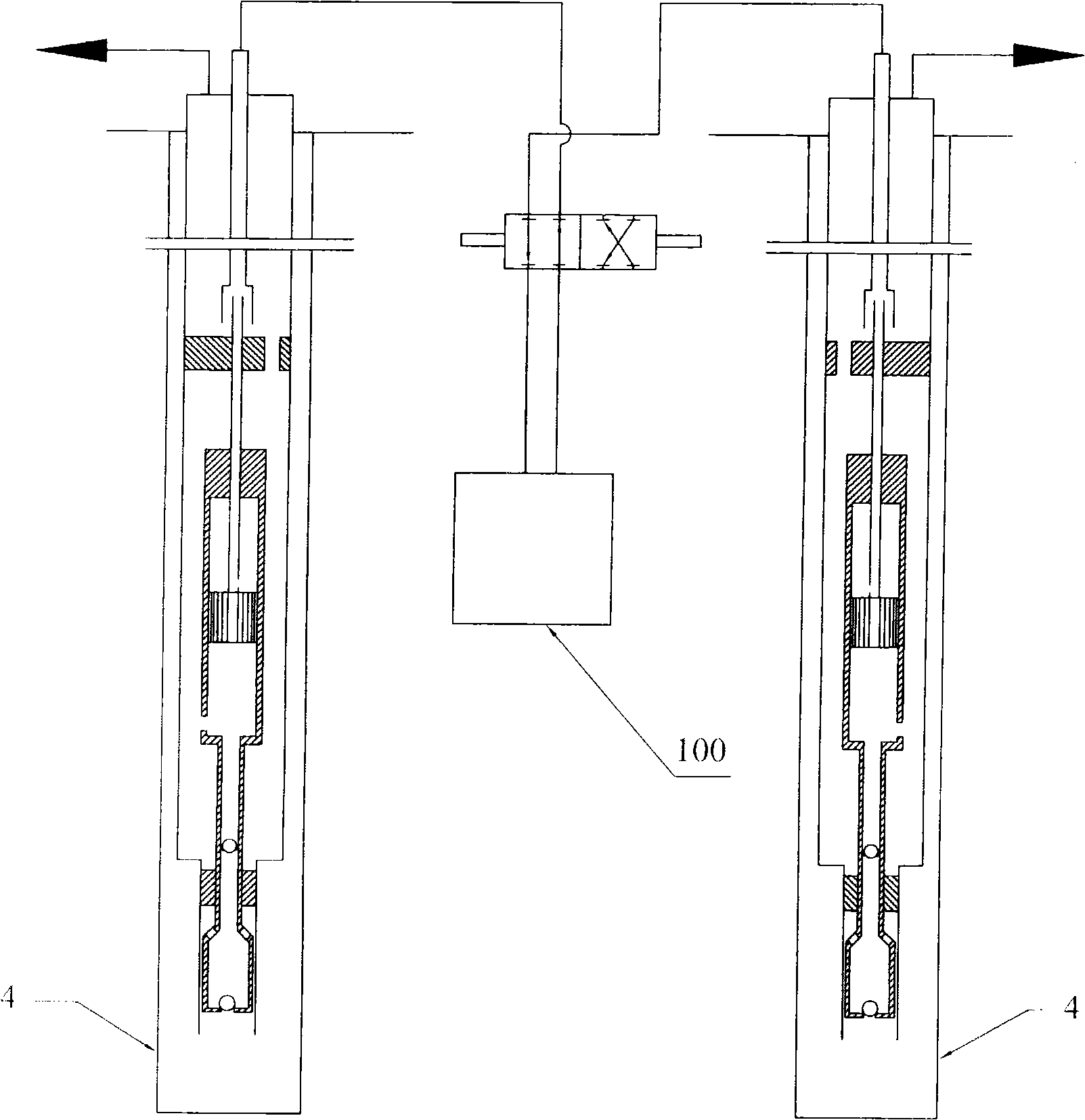

[0027] Such as figure 1 As shown, the oil well pump of the present invention is arranged in the casing 4 of the underground part, and is mainly composed of an oil pipe 3, a small pump barrel 9, and a large pump barrel 12 connected in series.

[0028] Wherein, the oil pipe 3 is provided with an upward pump barrel 5, the lower end of the upward pump barrel 5 is fixedly connected to a small plunger 7, and the lower end of the small plunger 7 is fixedly connected to a large plunger 10, and the inner cavities thereof are connected to each other. The small plunger 7 slides up and down in the small pump barrel 9, and the large plunger 10 slides up and down in the large pump barrel 12. A first oil port a is provided on the side wall of the upward pump barrel 5 near the small plunger 7. The inner cavity of the small plunger 7 is provided with an upper oil outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com