Soap-free color-fixing agent emulsion and preparation method thereof

A technology of fixing agent and emulsion, applied in dyeing method, textile and papermaking, etc., can solve the problems of not meeting people's requirements, singleness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A soap-free color-fixing agent emulsion, mainly composed of polymerized monomers, dispersion stabilizers, monomers carrying cations, cross-linking monomers, initiators, and deionized water, wherein 75 parts of polymerized monomers, dispersion stabilizers 10 parts, 60 parts of cationic monomer, 3 parts of cross-linking monomer, 0.5 part of initiator, 700 parts of deionized water.

[0043] Polymerized monomers include 30 parts of hard monomer and 45 parts of soft monomer. The hard monomer is acrylic acid, and the soft monomer is methyl acrylate and ethyl acrylate.

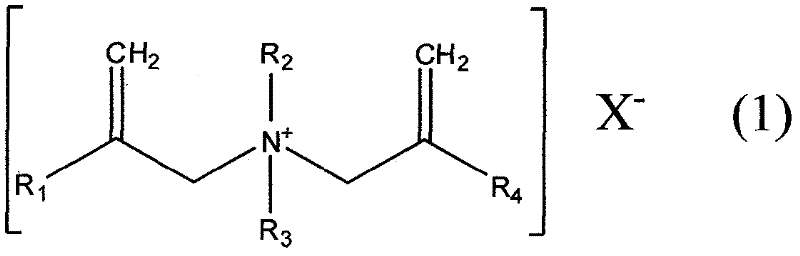

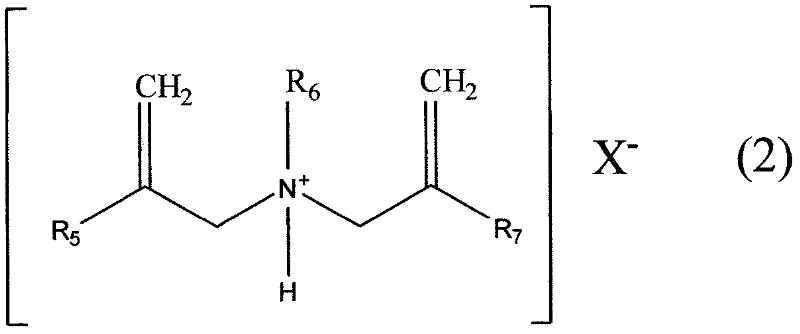

[0044] Cationic-carrying monomers include diallyldimethylammonium chloride, diallyldi(β-hydroxyethyl)ammonium chloride.

[0045] The cross-linking monomer is diacetone acrylamide / hexadihydrazine adipate.

[0046] The initiators are sodium persulfate and potassium persulfate.

[0047] The preparation method of above-mentioned soap-free color fixing agent emulsion, comprises the steps:

[0048] (1) Add 700 part...

Embodiment 2

[0056] A soap-free color-fixing agent emulsion, mainly composed of polymerized monomers, dispersion stabilizers, monomers carrying cations, crosslinking monomers, initiators, deionized water, wherein 90 parts of polymerized monomers, dispersion stabilizers 18 parts, 70 parts of cationic monomer, 3.5 parts of cross-linking monomer, 1 part of initiator, 800 parts of deionized water.

[0057] Polymerized monomers include 50 parts of hard monomer and 40 parts of soft monomer. The hard monomer is hydroxymethyl methacrylate and hydroxyethyl methacrylate, and the soft monomer is hydroxyethyl acrylate.

[0058] Cationic-carrying monomers include diallyl bis(β-ethoxyethyl)ammonium chloride, diallyldimethylammonium bromide.

[0059] The crosslinking monomer is γ-methacryloxypropyltriethylmethoxysilane.

[0060] The initiator is ammonium persulfate.

[0061] The preparation method of above-mentioned soap-free color fixing agent emulsion, comprises the steps:

[0062] (1) Add 800 parts...

Embodiment 3

[0070] A soap-free color-fixing agent emulsion, mainly composed of polymerized monomers, dispersion stabilizers, monomers carrying cations, crosslinking monomers, initiators, deionized water, wherein 100 parts of polymerized monomers, dispersion stabilizers 25 parts, 80 parts of cationic monomer, 4 parts of cross-linking monomer, 1.8 parts of initiator, 950 parts of deionized water.

[0071] Polymerized monomers include 55 parts of hard monomer and 45 parts of soft monomer, the hard monomer is hydroxypropyl methacrylate, and the soft monomer is hydroxybutyl acrylate.

[0072] Cationic-carrying monomers include diallyl bis(β-ethoxyethyl)ammonium chloride, diallyldimethylammonium chloride, diallyldimethylammonium bromide.

[0073] The crosslinking monomer is acryloxypropyltriethoxysilane.

[0074] The initiator is azobisisobutyronitrile.

[0075] The preparation method of above-mentioned soap-free color fixing agent emulsion, comprises the steps:

[0076] (1) Add 950 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com