Blood separating gel filling machine

A blood separation and injection technology, which is applied in bottle perfusion, liquid bottling, liquid treatment, etc., can solve the problems of increasing production cost, easy to mix with air, and reducing the amount of glue added, so as to prevent the production of glue threads and reduce labor. Strength, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

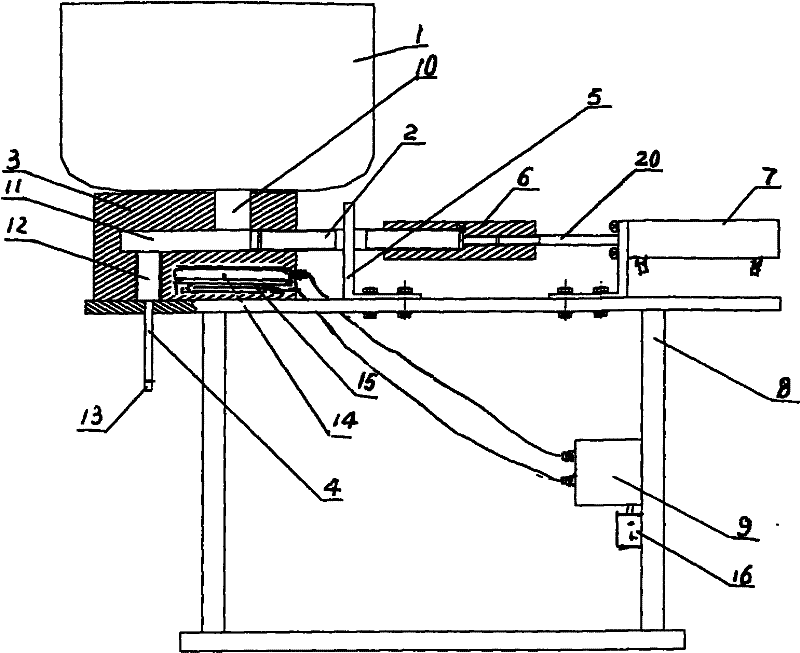

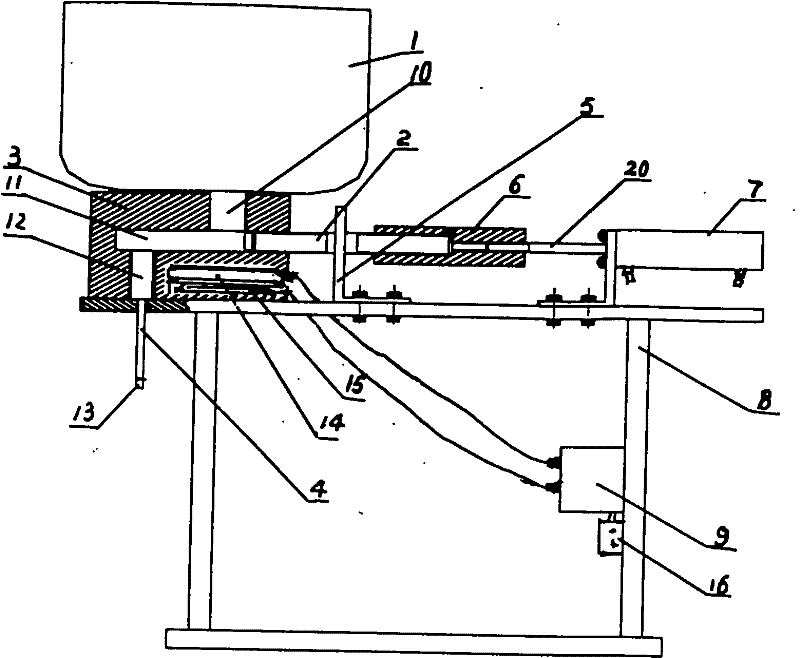

[0014] Refer to attached figure 1 , 2 , The blood separation glue filling machine is made up of frame 8, constant temperature heater, quantitative filling device. The quantitative filler includes a quantitative filler body 3 , a filling head 4 , a push rod 2 , a filling volume adjustable plate 5 , a connecting head 6 , a cylinder 7 and a rubber barrel 1 . The quantitative injector body 3 is installed on the upper part of the frame 8. The quantitative injector body 3 is equipped with a quantitative cavity 11, and the upper part of the quantitative cavity 11 is provided with a glue inlet 10, and the lower part of the quantitative cavity 11 is provided with a glue outlet 12. . The glue barrel 1 is installed on the upper part of the quantitative filling body 3, and the glue outlet of the glue barrel 1 is connected with the glue inlet 10 of the quantitative chamber 11. A filling head 4 is installed on the glue outlet 12 at the bottom of the quantitative cavity 11 . A glue injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com