Full-automatic winch take-up system

A technology of tensioning system and automatic control system, applied in the field of automatic winch tensioning system, can solve the problems of many control links, overall scattered, complicated installation, etc., to achieve stable and precise tension control, fast tension control, and simple control links Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

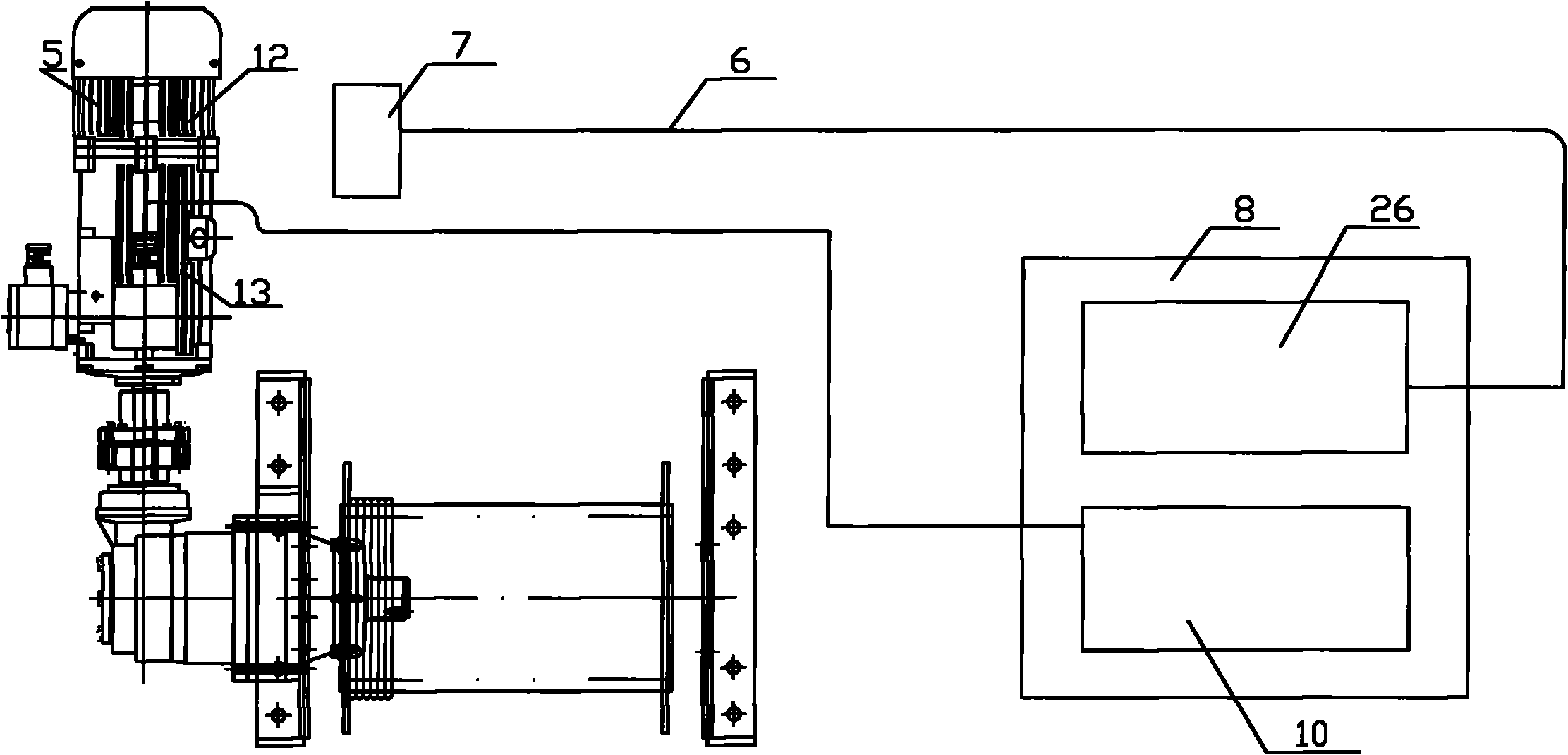

[0037] Embodiment 1: as figure 2 As shown, the automatic winch tensioning system 1 of the present invention is installed with the fixed reverse drum 2, the belt trolley 3 and the belt storage bin 4 to form a system, wherein the automatic winch tensioning system 1 includes an electromagnetic brake tensioning winch 5. Auxiliary tensioning device 6, detection system 7 and tension control system 8; the fixed reverse roller 2 is fixedly installed on the fixed section of the storage bin 4, and the electromagnetic brake tensioning winch 5 is fixedly installed on the side of the storage bin 4 On the tensioning section, the belt trolley 3 is placed on the running guide rail of the belt storage bin 4, and is respectively connected with the fixed reverse roller 2 and the fixed wheel on the electromagnetic brake tensioning winch 5 through the auxiliary tensioning device 6, and the belt The trolley 3 moves horizontally between the two end tape storage bins 4; the detection system 7 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com