Double-layer injection mold

A double-layer injection molding and mold technology, which is applied in the field of plastic molds, can solve the problems of inability to install small injection machines, increase the length and width of molds, and increase injection molding costs, so as to avoid increased injection molding costs, improve production efficiency, and occupy less space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

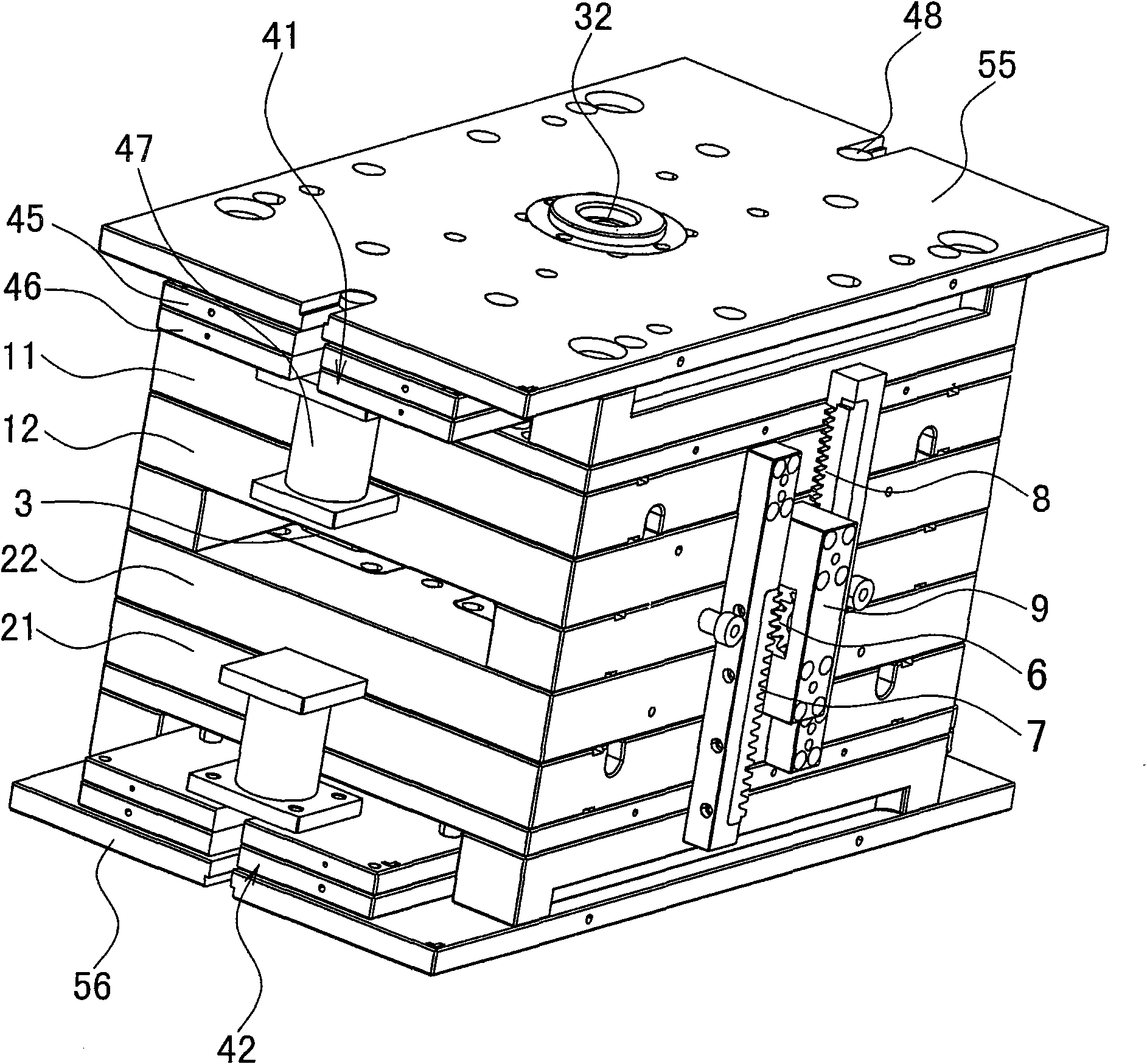

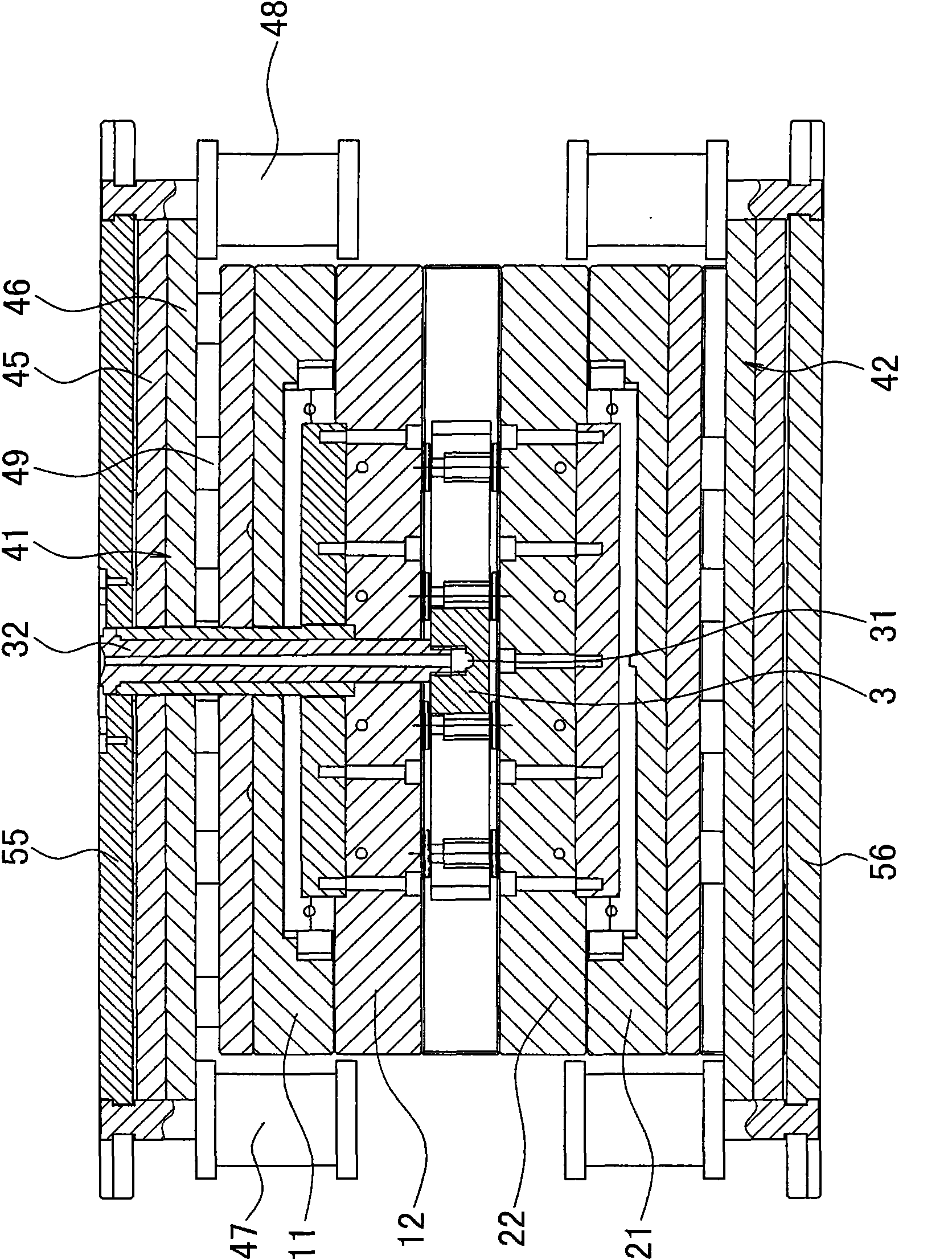

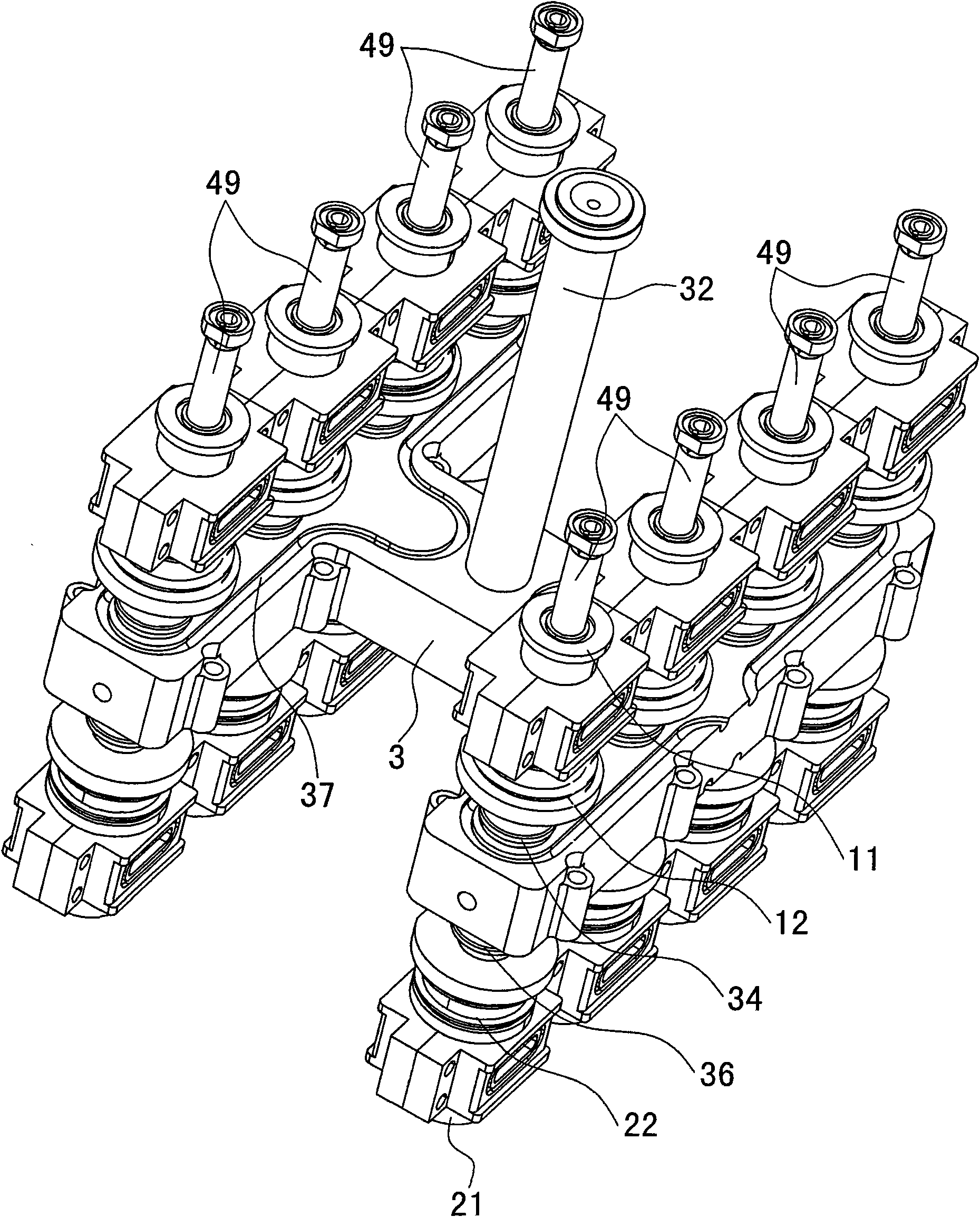

[0012] The present invention relates to a double-layer injection mold, such as Figure 1-Figure 5 As shown, including the core and the cavity, the core and the cavity constitute the cavity of the product, the cavity is two or more, the core and the cavity can be integrally manufactured, but because the cavity and the core The required materials are better. In order to save precious metal materials and reduce costs, the cavity and core are generally manufactured separately, such as image 3 , Figure 4 As shown, the cavity and the core used for the molding part are made into inserts respectively, and then the inserts are inserted into the cavity fixing plate and the core fixing plate, and the cavity fixing plate and the core fixing plate can be used For ordinary materials, when there are many cavities, there are multiple cavity inserts and core inserts, each forming a cavity. The products in the cavity are driven by the ejector mechanism, and the outer wall of the cavity is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com