Novel gas-liquid two-phase feeding distribution structure

A feeding distribution pipe and feeding technology, applied in the chemical industry, can solve problems affecting uniformity, affecting liquid flow and gas-liquid separation, reducing tower separation accuracy and operational stability, etc., to reduce operating energy consumption and improve separation and distribution effect, the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

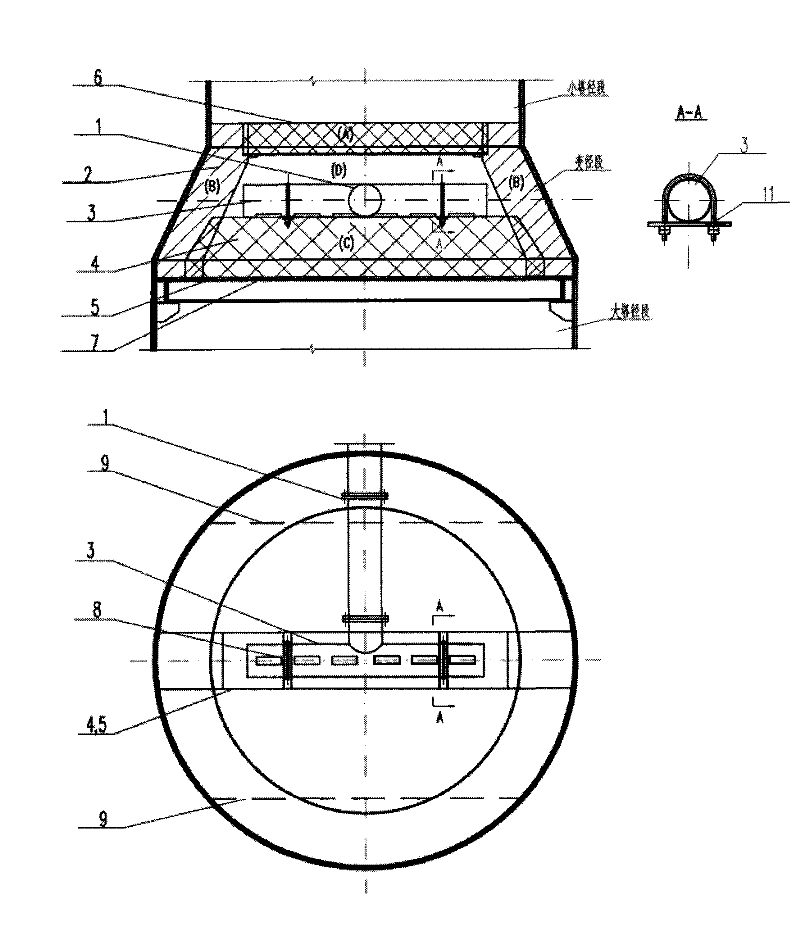

[0020] Example 1 as figure 1 As shown, a gas-liquid two-phase feed distribution structure used in the stabilizing tower, the stabilizing tower consists of small tower diameter section, variable diameter section and large tower diameter section from top to bottom, The material distribution structure is located in the variable diameter section of the stabilizing tower, including the upper tray 6, the upper downcomer 2, the open downcomer 4, the lower liquid tray 5, the lower tray 7, the feed main pipe 1 and the feed Distribution pipe 3.

[0021] The upper floor tray 6 is located at the bottom of the small tower diameter section of the stable tower, and is a double overflow tray; the upper floor downcomer 2 is located below the upper floor tray 6, and the lower floor tray 7 is located at the bottom of the stable tower. On the upper part of the large tower diameter section, on both sides of the lower tray near the tower wall are the downcomers 9 on both sides of the lower floor, ...

Embodiment 2

[0026] Example 2 as figure 2 As shown, its difference from Embodiment 1 is that the upper downcomer and the lower liquid receiving pan 5 are vertical at 90 degrees. The upper layer downcomer is the downcomer 10 on both sides of the upper layer, which is downward along both sides of the tower wall at the variable diameter section; an open downcomer 4 is separately arranged above the liquid receiving plate 5 in the middle of the lower layer; the downcomer 4 on both sides of the upper layer The two ends of the pipe 10 and the open downcomer 4 are sealed and penetrated, and the sealing and penetration here is realized by the following method: after the downcomer 10 on both sides of the upper layer intersects with the two ends of the open downcomer 4, the figure 2The part outside the middle C area is closed, that is to say, the intersections of the two ends of the open downcomer 4 and the two lower ends of the downcomer 10 on both sides of the upper layer are respectively fused t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com