Wedge-shaped cutting and binding apparatus

A wedge-shaped and device technology, applied in the field of medical devices, can solve problems such as complicated surgical procedures and the impact on the patient's body, and achieve the effects of small device structure, simple use, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

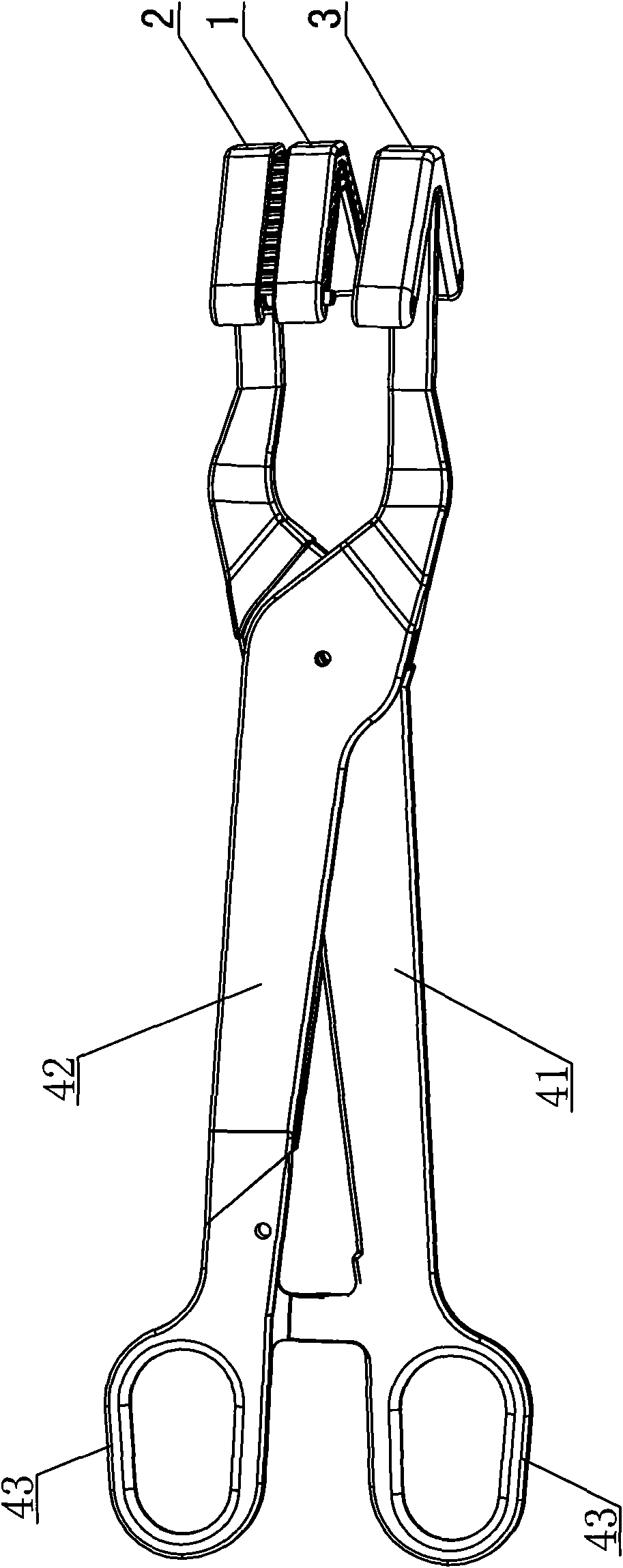

[0024] The invention discloses a wedge cutting and binding instrument, such as figure 1 As shown, it includes a staple cartridge 1, a nail pusher seat 2 and an anvil 3, and a first clip seat 41 and a second clip seat 42 hinged to each other, and the described nail pusher seat 2 is fixed on the first clip seat 41. At the front end, the anvil 3 is fixed on the front end of the second clamping seat 42 , and the rear ends of the first clamping seat 41 and the second clamping seat 42 are both clamping seat handles 43 . As in the prior art, the staple cartridge 1 and the staple anvil 3 are arranged opposite to each other to form a suturing area of the instrument, and the tissue to be sewn is placed between the two.

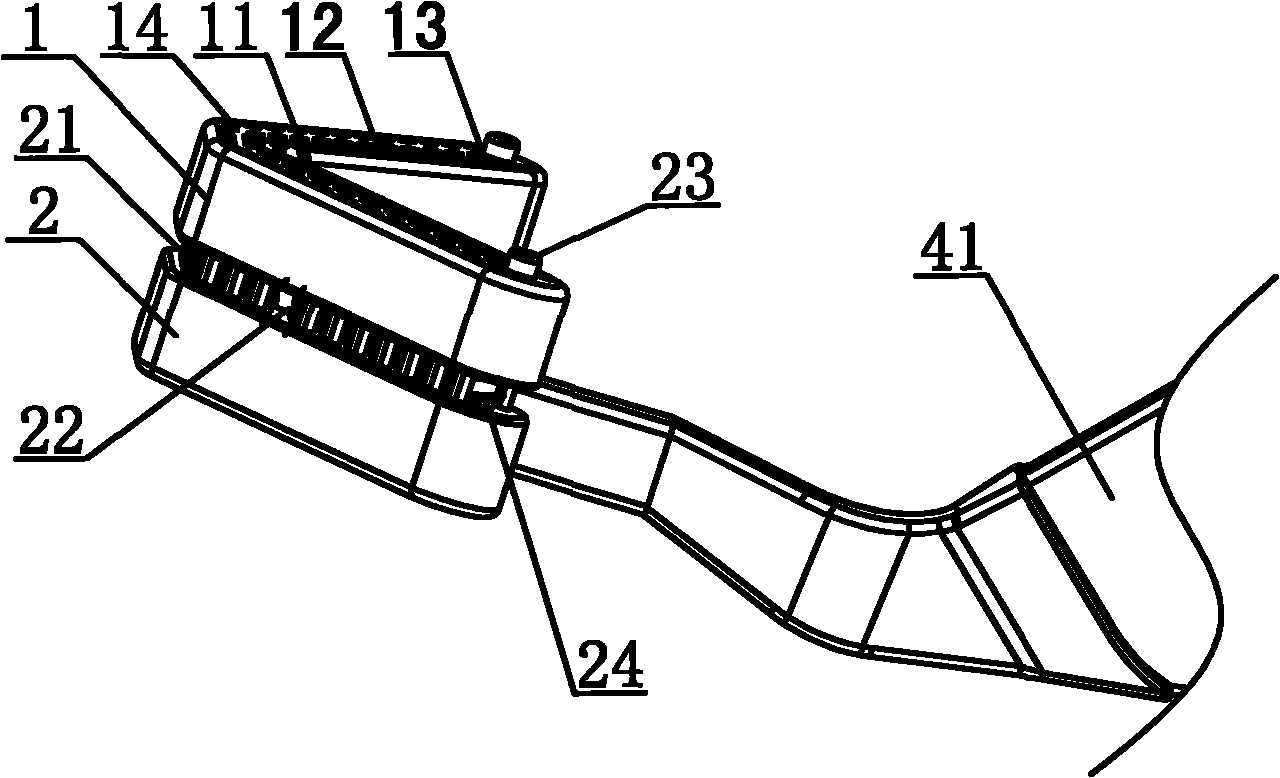

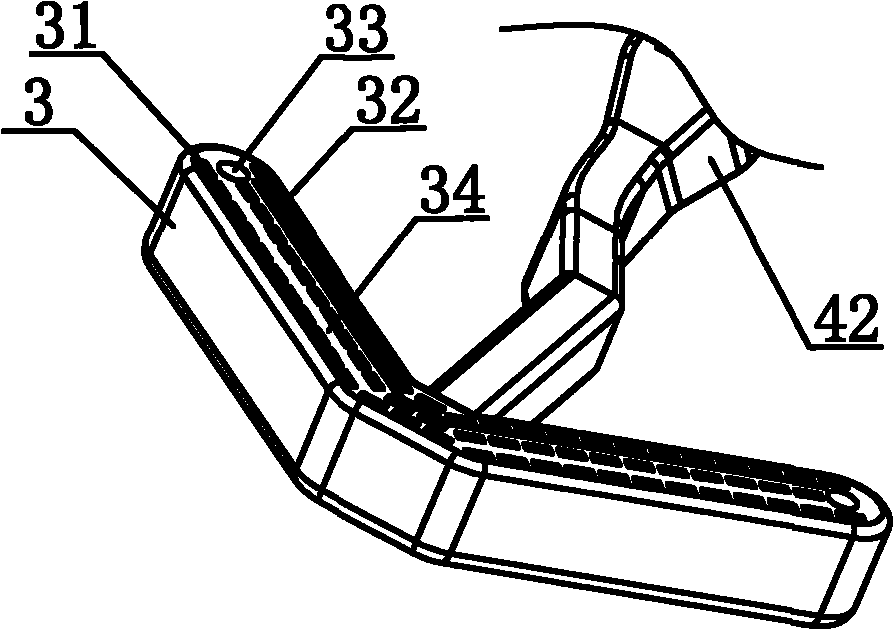

[0025] In the present invention, combining figure 2 As shown in FIG. 4 , the outer contours of the nail cartridge 1 , the nail pusher seat 2 and the nail anvil 3 are consistent, and they are all arranged in a wedge shape. The surface 14 of the staple cartridge 1 op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com