Drying tower with multi-helical structure and drying method

A technology of spiral structure and drying tower, which is applied in application, food preparation, food science, etc., to achieve the effect of avoiding uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A drying tower comprising the following parts:

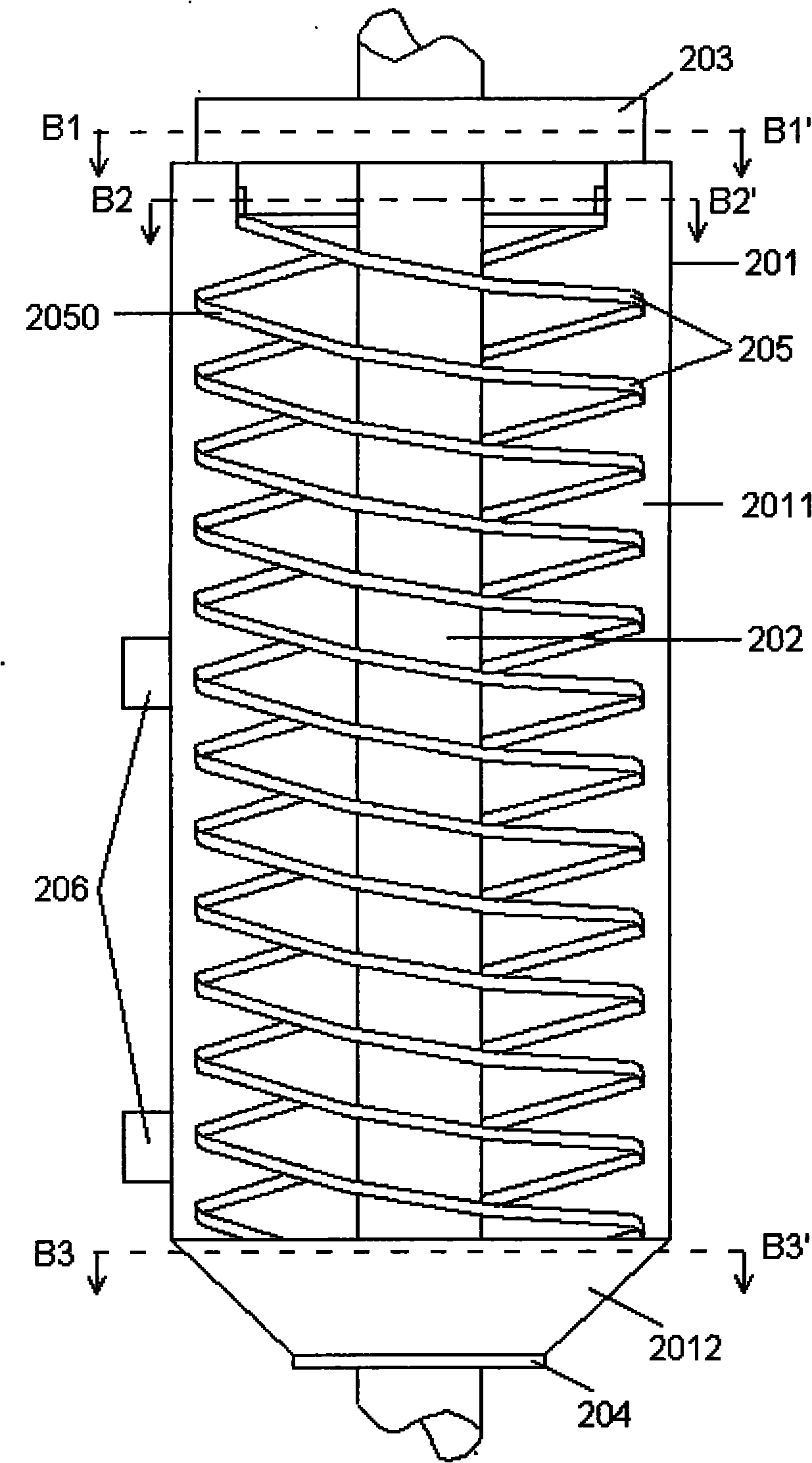

[0067] according to figure 1 :

[0068] A drying tower includes a shell 201 , a rotating shaft 202 , a material inlet 203 , a material outlet 204 , a spiral material channel 205 , and a rotating wind generator 206 .

[0069] The casing 201 includes a cylindrical tower drying chamber 2011 at the upper part and a conical storage chamber 2012 at the lower part.

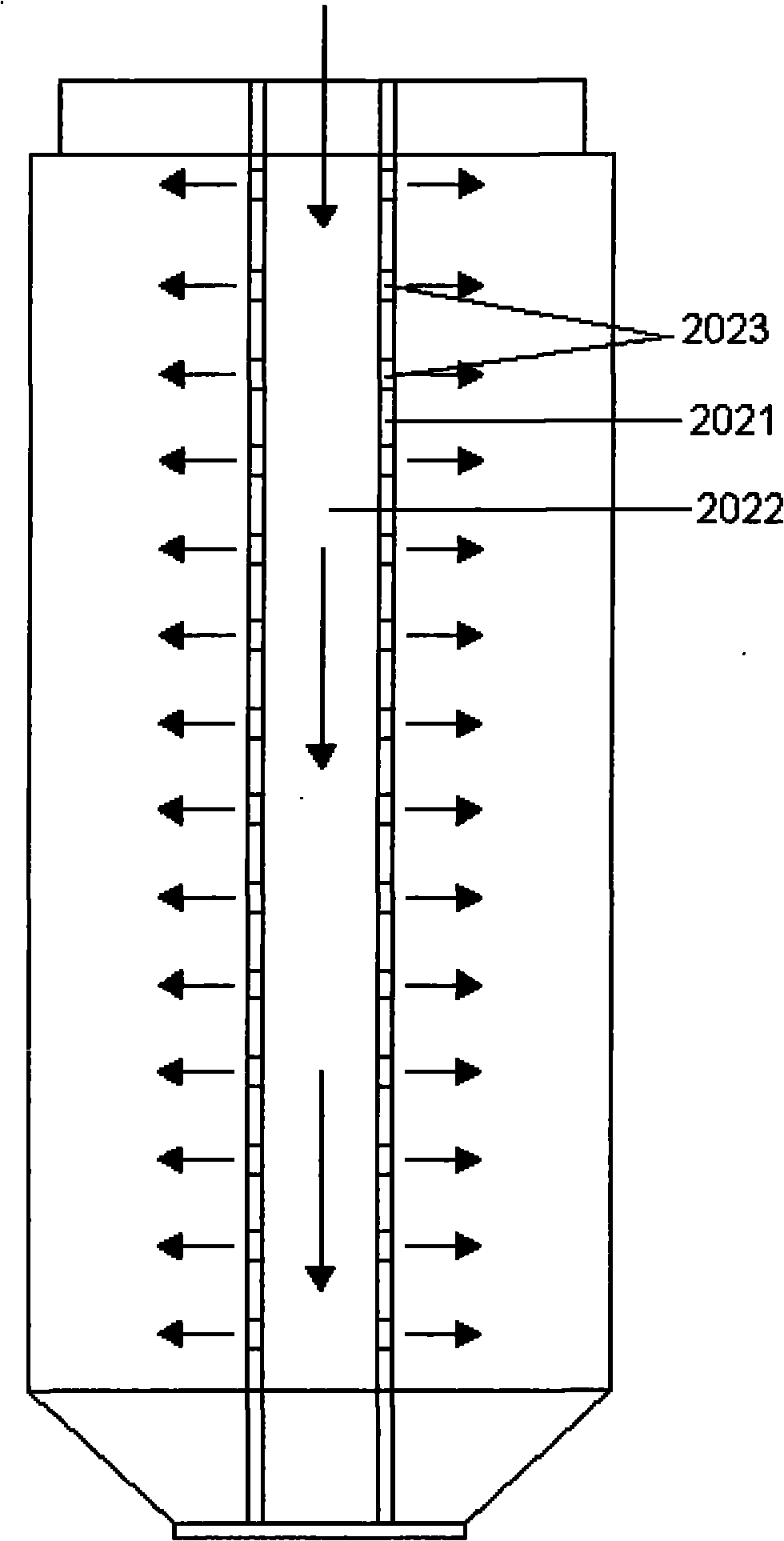

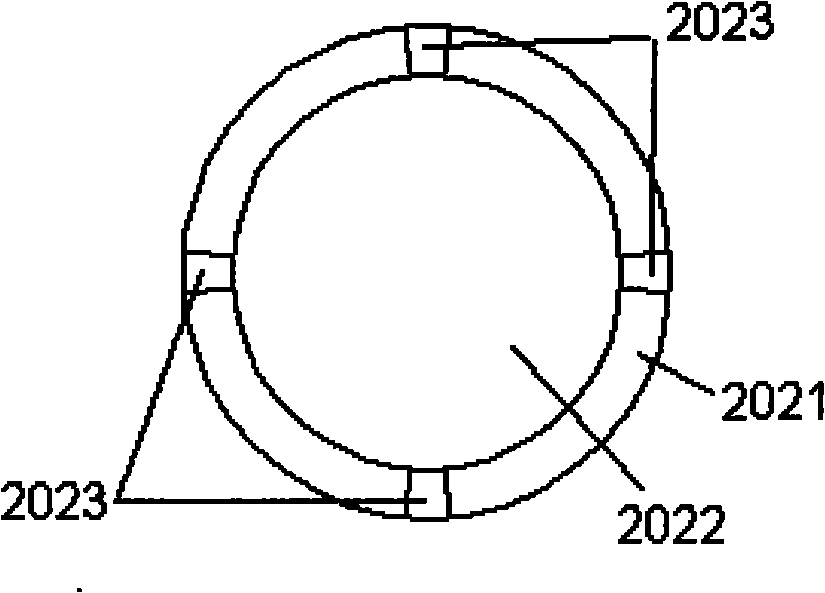

[0070] according to Figure 2a and 2b :

[0071] The rotating shaft 202 is located at the center of the casing 201 , passing through the axes of the tower drying chamber 2011 and the conical storage chamber 2012 in sequence. The rotating shaft 202 includes a shaft housing 2021 , a shaft cavity 2022 surrounded by the shaft housing 2021 and a set of one-way holes 2023 disposed on the shaft housing 2021 .

[0072] The one-way hole 2023 passes through the shaft housing 2021 and communicates with the shaft cavity 2022 to allow the gas inside the shaft cavity 2022 t...

Embodiment 2

[0114] Adopt the following technical parameters to improve embodiment one:

[0115] The spiral material channel 205 is a set of spiral slides 2050 rotating around the shaft 202 , including two spiral slides 2050 .

[0116] In the spiral slideway 2050, the angle b1 between the retaining structure 2053 and the spiral structure 2052 is 81°.

[0117] The slope b5 between the spiral structure 2052 and the horizontal plane is 11°.

[0118] In the feed port 203, the central angle b2 of the material feed port 2035 is 90°.

[0119] In the discharge port 204, the central angle b3 of the storage chamber 2042 is 90°.

[0120] The drying device includes one rotating wind generator 206, and the angle b4 formed between the air outlet 2063 and the horizontal plane is 68°.

Embodiment 3

[0122] Adopt the following technical parameters to improve embodiment one:

[0123] The spiral material channel 205 is a set of spiral slides 2050 rotating around the shaft 202 , including two spiral slides 2050 .

[0124] In the spiral slideway 2050, the angle b1 between the retaining structure 2053 and the spiral structure 2052 is 91°.

[0125] The slope b5 between the spiral structure 2052 and the horizontal plane is 21°.

[0126] In the feed port 203, the central angle b2 of the material feed port 2035 is 50°.

[0127] In the discharge port 204, the central angle b3 of the storage chamber 2042 is 50°.

[0128] The drying device includes two rotating wind generating devices 206, and the angle b4 between the air outlet 2063 and the horizontal plane is 65°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com