Self-moving type reversed loader for coal mine

A self-moving reloading machine and coal mine technology, which is applied in the fields of earth drilling, transportation and packaging, underground transportation, etc., can solve the problems of wasteful use and poor effect of large-scale mechanized devices, and achieve the goal of maintaining the quality of coal output, not easily falling off the road, Use flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

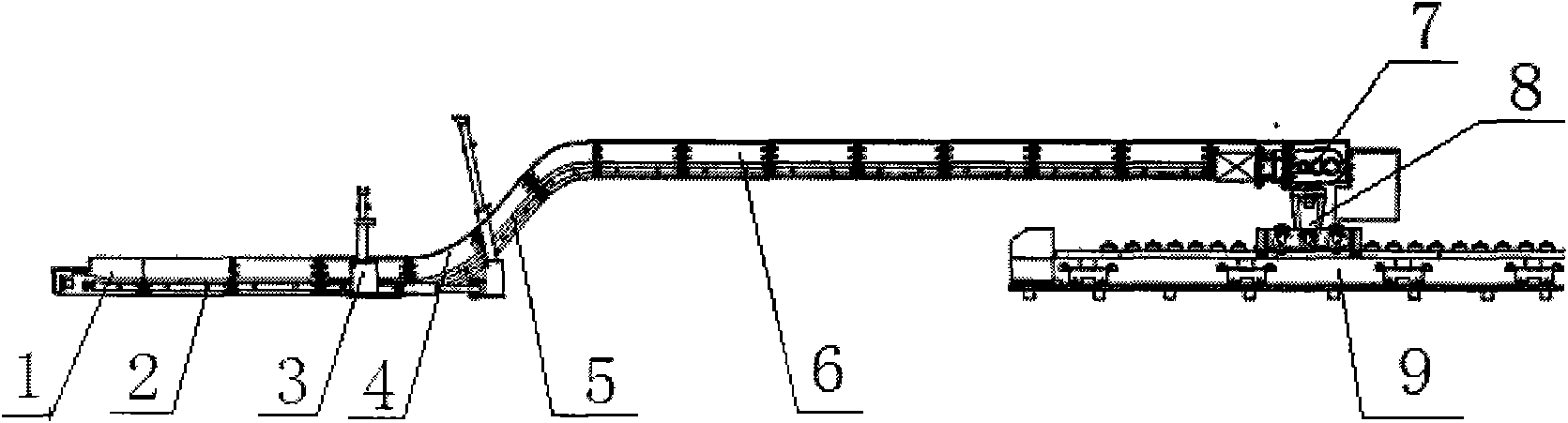

[0037] Such as figure 1 As shown, a self-moving transfer machine for coal mines includes a tail assembly 1 connected in sequence, a bottom plate 2 composed of a coal receiving trough, and a number of transport troughs; a lower curved trough 4 and an upper curved trough 5; and a bridge composed of several transport troughs Section 6, the nose 7 of the bridge, is provided with a scraper conveyor chain on the transport trough between the tail assembly 1 and the position of the nose 7, and a walking trolley 8 is provided under the nose 7 connected to the bridge. The trolley 8 is also connected with a coal receiving device, the walking trolley 8 and the coal receiving device are erected on the transport frame 9, and automatic moving devices 3 are also provided on both sides of the bottom plate 2.

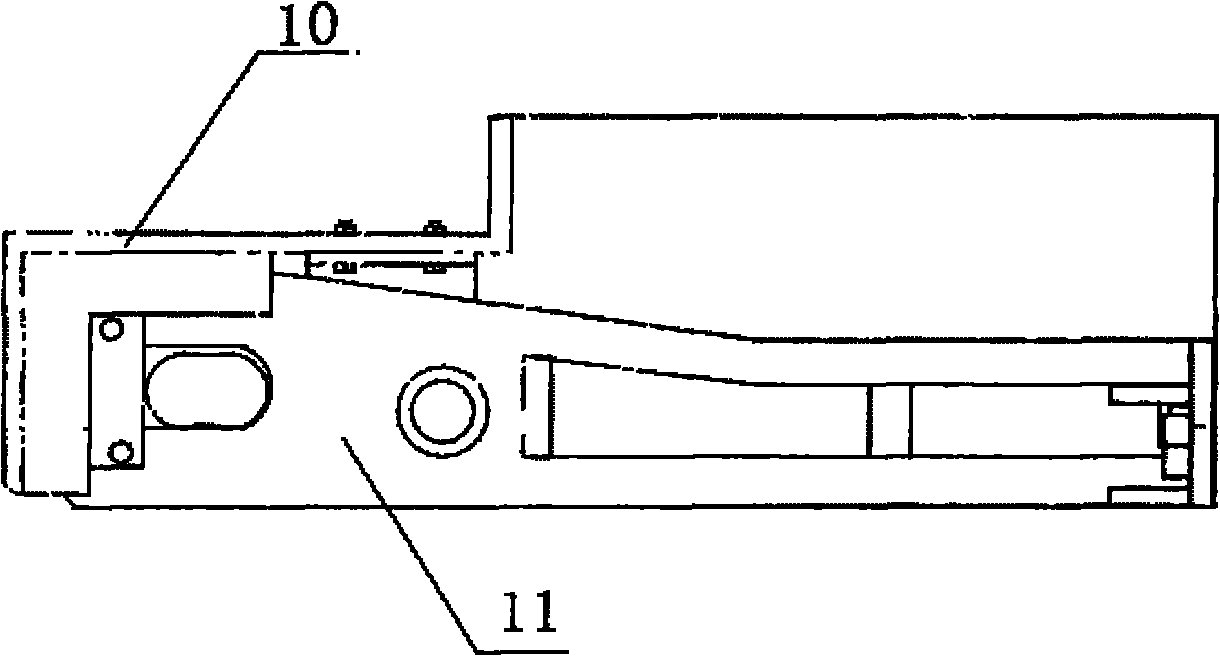

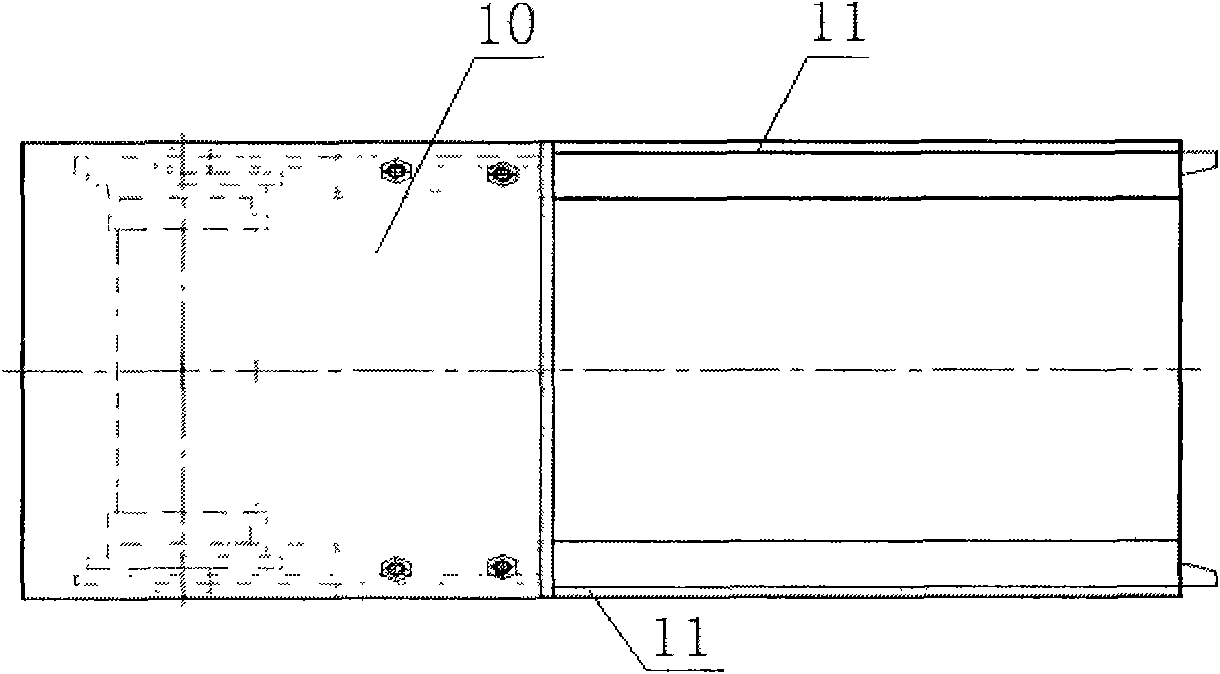

[0038] Such as figure 2 As shown, the rotating roll of the tail assembly 1 is provided with a cover plate 10, and two baffles 11 are provided on both sides, which can ensure the absolute sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com