Method and device for cleaning aluminum alloy radiating fin

A technology for heat sinks and aluminum alloys is applied in the field of cleaning devices for aluminum alloy heat sinks to achieve the effects of saving cleaning raw materials, improving efficiency and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

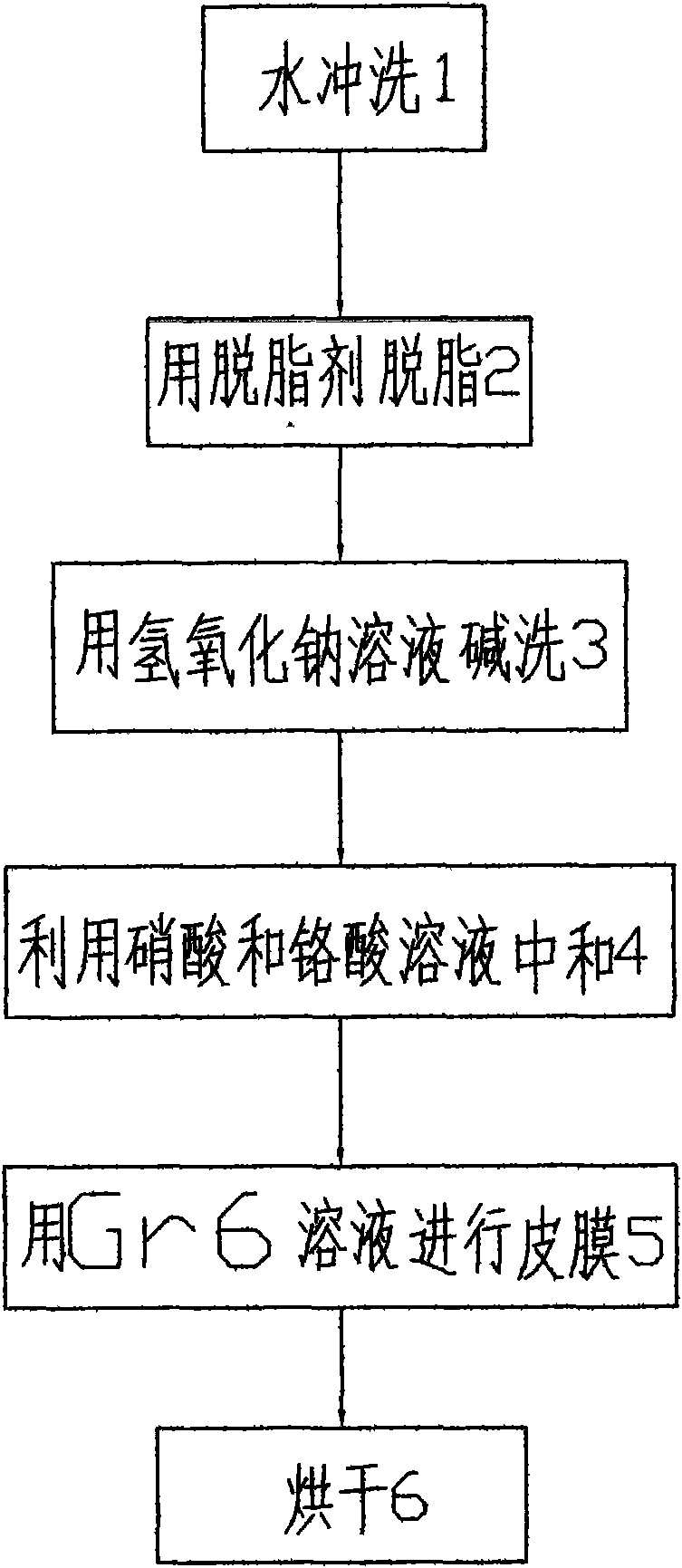

[0039] like figure 1 Shown is a method for cleaning aluminum alloy heat sinks, the steps of the method are:

[0040] 1. Rinse the aluminum alloy heat sink with water to remove dirt and aluminum chips;

[0041] 2. Use a degreasing agent to remove oil and impurities on the surface of the aluminum alloy heat sink;

[0042] 3. Alkali washing the aluminum alloy heat sink with sodium hydroxide solution to remove the burrs of the aluminum alloy heat sink after degreasing;

[0043] 4. Use nitric acid and chromic acid solutions to neutralize the alkaline compounds remaining on the surface of the aluminum alloy heat sink after alkaline cleaning, and remove the surface alkaline compounds;

[0044] 5. Use film agent (Gr6) to treat the surface of the aluminum alloy heat sink, so that the surface of the aluminum alloy heat sink is covered with a protective film.

[0045] 6. Dry or dry the aluminum alloy heat sink.

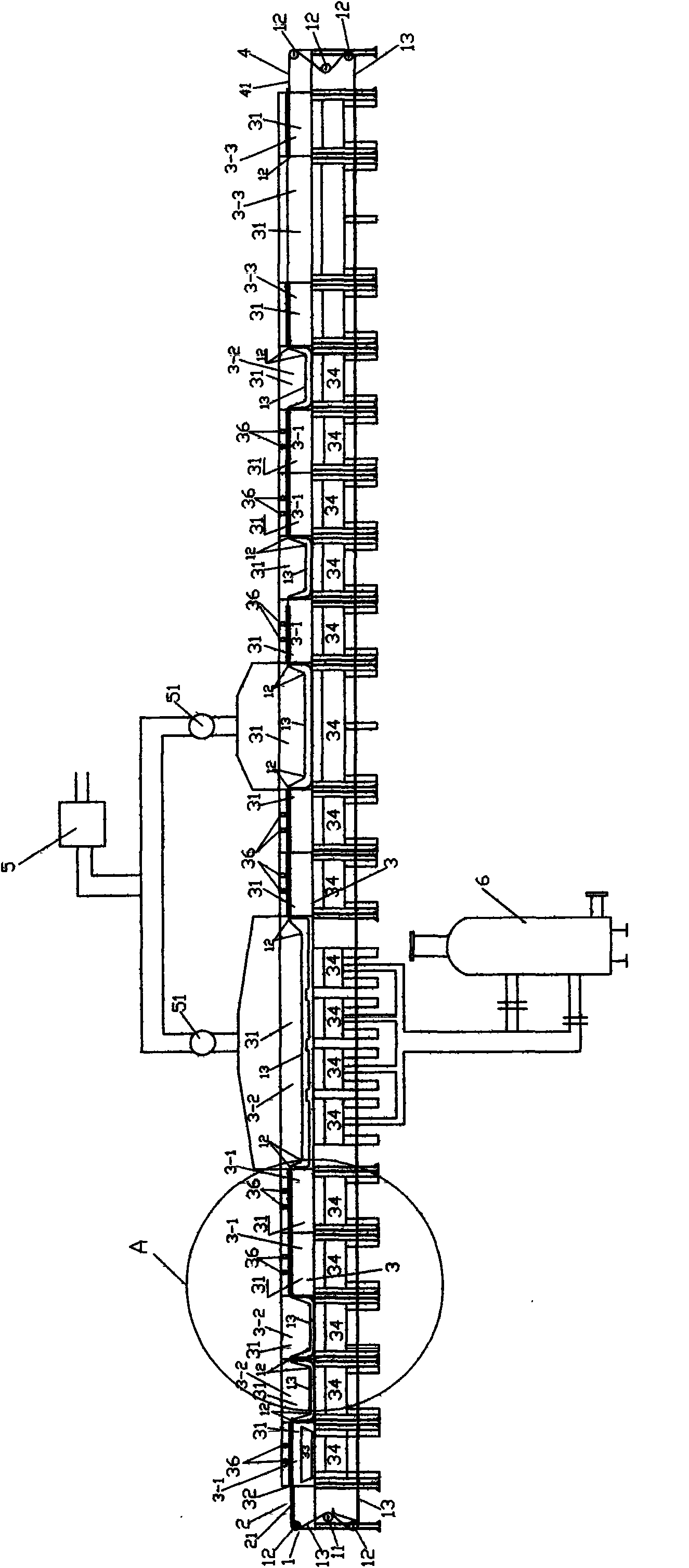

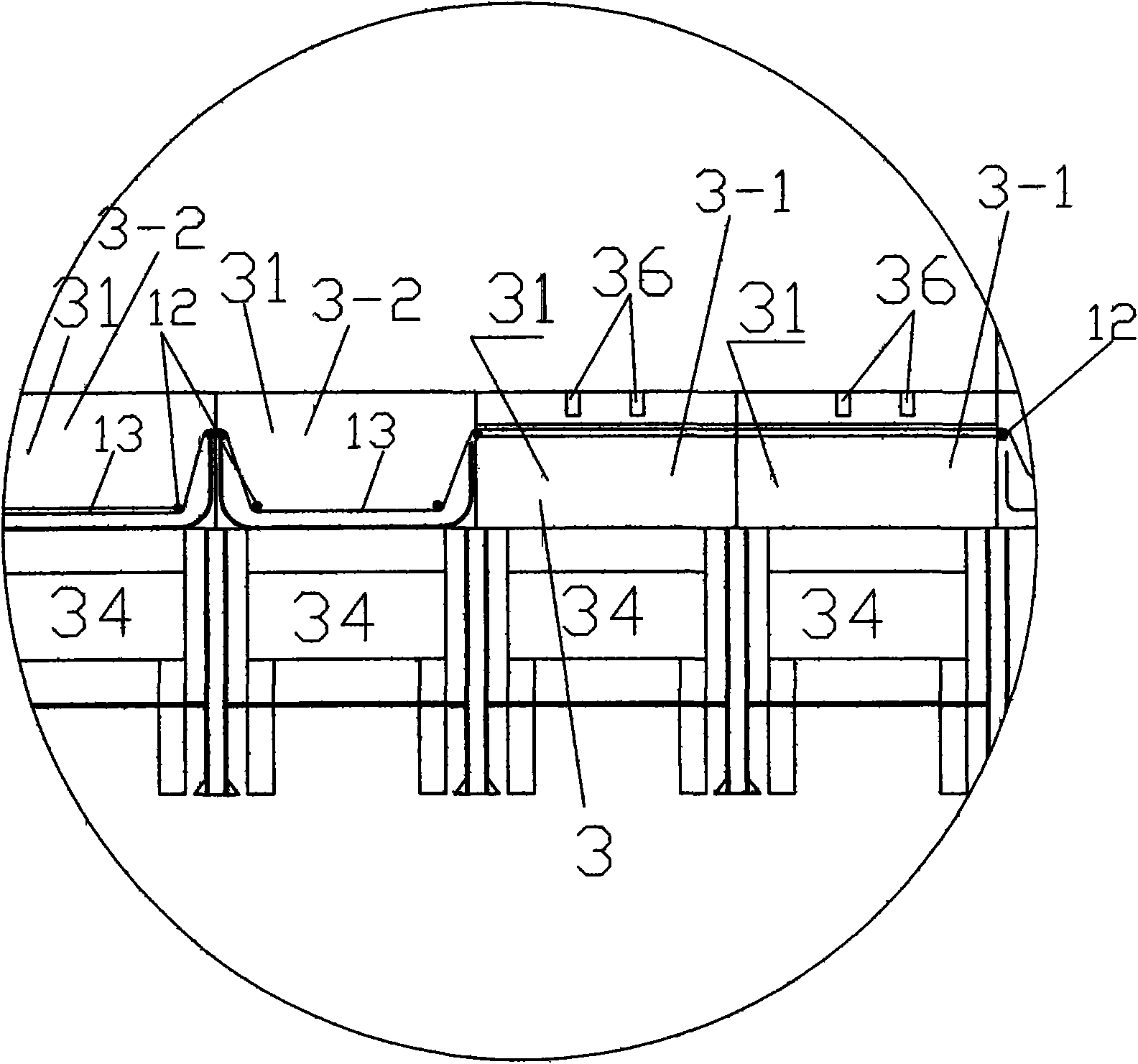

[0046] like Figure 2 to Figure 9 As shown, the device of the method f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com