Dry preparation method of starch sugar

A technology of starch sugar and starch syrup, which is applied in the dry preparation of starch sugar and the preparation of starch sugar powder. It can solve the problems that water is not easy to volatilize, affect product quality, and the viscosity of starch sugar is high, so as to avoid sticking phenomenon and automate The effect of high degree and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

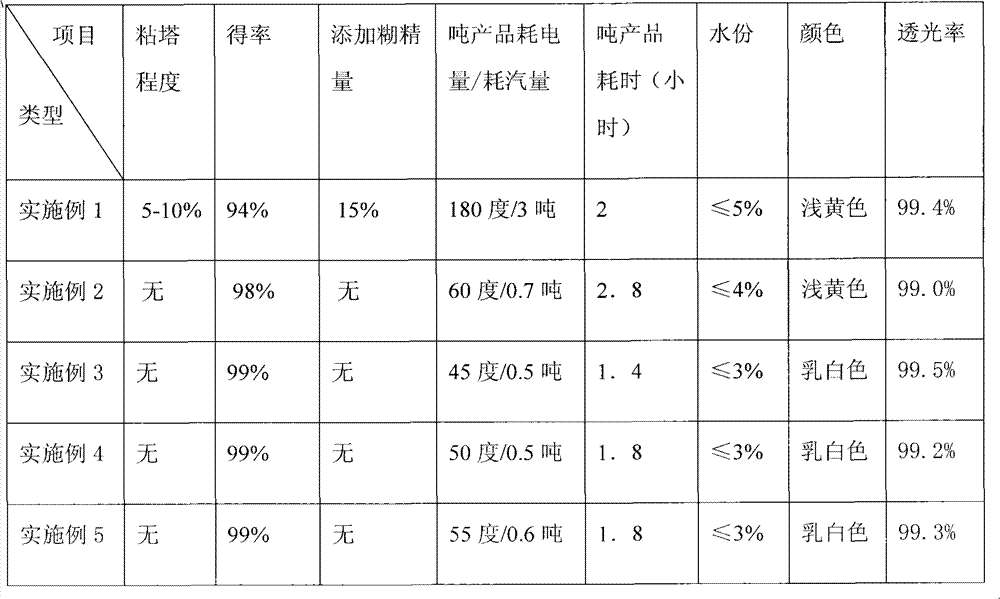

Examples

Embodiment 1

[0032] (1) Preparation of fructo-oligosaccharide syrup: sucrose was used as raw material to prepare fructo-oligosaccharide syrup. After decolorization, refining and concentration, fructo-oligosaccharide syrup with a concentration of 78wt% was obtained.

[0033] (2) Spray drying: add 15% dextrin to the fructooligosaccharide syrup obtained in step 1, and spray dry. The moisture content of the finished product is ≤5%.

[0034] (3) Pulverization: the product obtained in step 2 is pulverized by a direct classification pulverization method; the mesh number range of the obtained fructooligosaccharide powder is 40~80 orders.

Embodiment 2

[0036] (1) Preparation of fructo-oligosaccharide syrup: sucrose was used as raw material to prepare fructo-oligosaccharide syrup. After decolorization, refining and concentration, fructo-oligosaccharide syrup with a concentration of 78wt% was obtained.

[0037] (2) Vacuum drying: the fructo-oligosaccharide syrup obtained in step 1 is placed in a belt-type vacuum continuous low-temperature dryer with relevant parameters set, and dried. Among them, the drying temperature is 100-110°C, the vacuum degree is -0.085MPa, the running speed of the belt is 10cm / min-15cm / min, the drying time is 2.8h, and the moisture content of the product is ≤4%.

[0038] (3) Pulverization: the fructooligosaccharide cake product obtained in step 2 is pulverized by a direct classification pulverization method; the mesh number range of the obtained fructooligosaccharide powder is 40~80 orders.

Embodiment 3

[0040] (1) Preparation of maltose syrup: starch is used as raw material to make maltose syrup, which is decolorized, refined and concentrated to obtain maltose syrup with a concentration of 83 wt%.

[0041](2) Vacuum drying: place the maltose syrup obtained in step 1 in a belt-type vacuum continuous low-temperature vacuum dryer, and pass through the first drying zone, the second drying zone, the third drying zone and the cooling zone in sequence; through the first drying zone The time is 6 minutes, the temperature of the first drying zone is 140°C, the vacuum degree is -0.088MPa; the time of passing through the second drying zone is 1.2 hours, the temperature of the second drying zone is 90°C, and the vacuum degree is -0.06Mpa; The time for the third drying zone is 15 minutes, the temperature of the third drying zone is 105° C., and the vacuum degree is -0.08 MPa; the time for passing through the cooling zone is 20 minutes, and the temperature of the cooling zone is 10° C. Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com