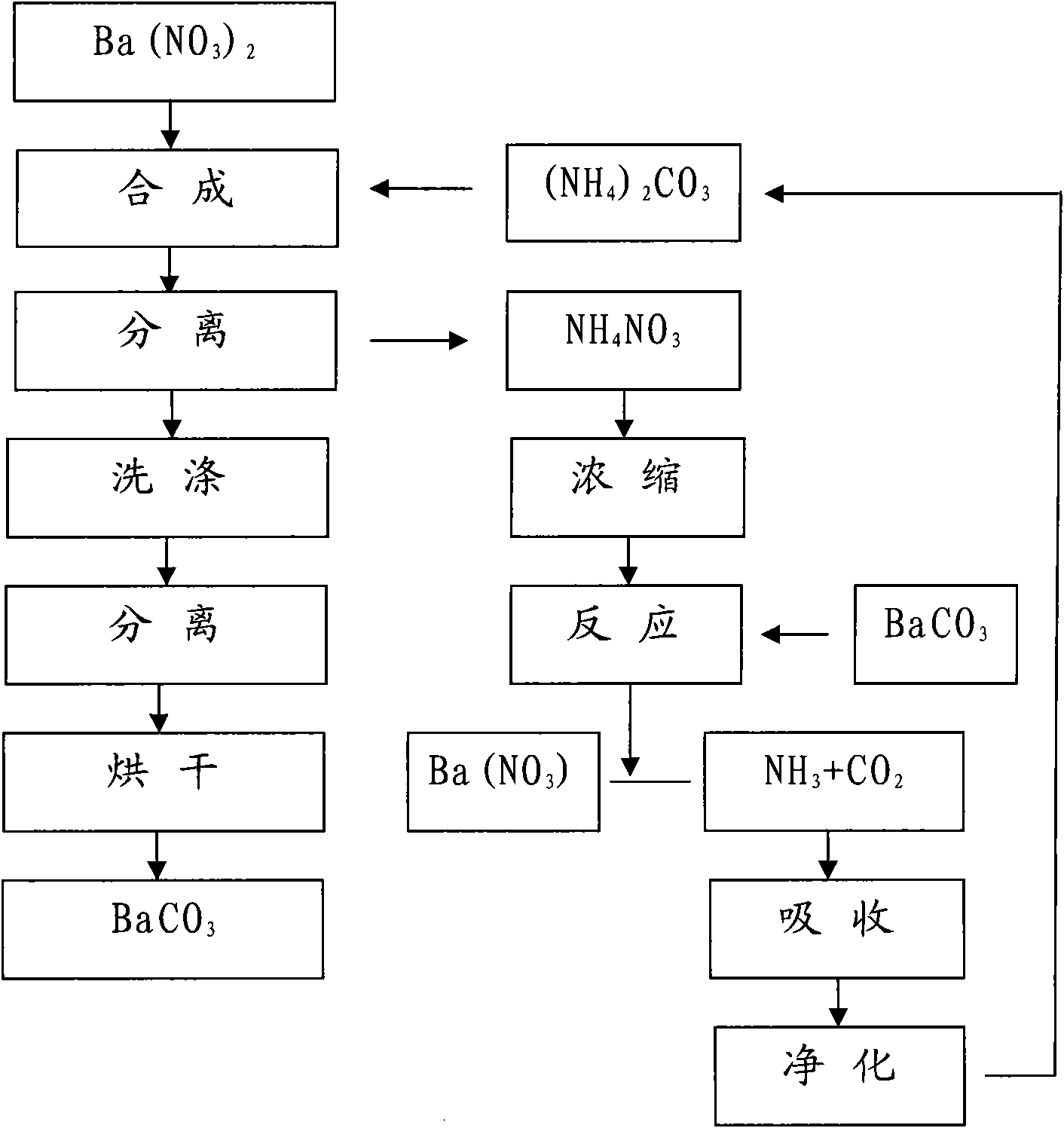

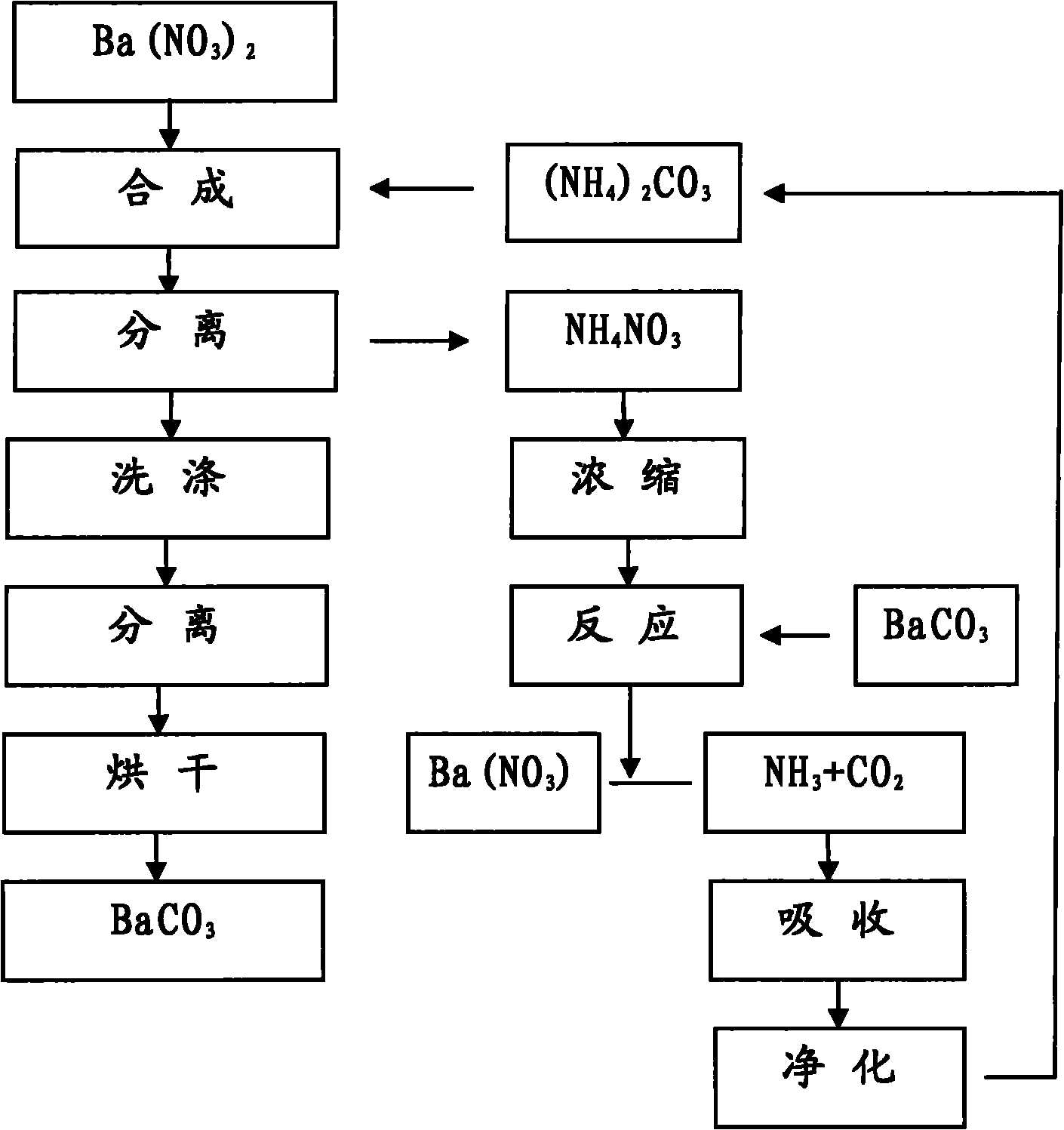

Method for producing BaCO3 through cyclically recovering and reusing (NH4)2CO3

A technology of recycling and absorbing liquid, applied in the direction of ammonium carbonate/acid carbonate, calcium carbonate/strontium/barium, etc., can solve the problem of high energy consumption, difficulty in washing chloride ions, and difficulty in handling high-impurity mother liquor, etc. problem, to achieve the effect of simple washing and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Will [Ba 2+ ] 3000ml of 0.85mol / L barium nitrate solution is placed in a 5000ml beaker, heated to boil, stop heating, add 3.0mol / L (NH 4 ) 2 CO 3 900ml, the adding speed is controlled at about 1.5L / hour.

[0018] Suction filter and separate the above synthetic materials, rinse with a small amount of hot deionized water, combine the filtrate into the recovery system, heat wash the filter cake at 100°C for 1 hour at a material-to-water ratio of 1:5, separate by suction filtration, and place it in an oven at 180°C for drying Dry for 16 hours to obtain BaCO 3 sample 1 # .

Embodiment 2

[0020] Will [Ba 2+ ] 3000ml of 0.83mol / L barium nitrate solution is placed in a 5000ml beaker, heated to boil, stop heating, add 2.15mol / L (NH 4 ) 2 CO 3 1220ml, control the adding speed at about 2.0L / hour.

[0021] The above-mentioned synthetic materials are separated by suction filtration, rinsed with a small amount of hot deionized water, and the combined filtrate enters the recovery system. The filter cake is heated at 100°C for 1 hour at a material-to-water ratio of 1:5, then separated by suction filtration, and dried in an oven at 180°C. Dry for 16 hours to obtain BaCO 3 sample 2 # .

Embodiment 3

[0023] Will [Ba 2+ ] 3000ml of 0.40mol / L barium nitrate solution is placed in a 5000ml beaker, heated to boil, stop heating, add 2.0mol / L (NH 4 ) 2 CO 3 630ml, control the adding speed at about 2.0L / hour.

[0024] The above-mentioned synthetic materials are separated by suction filtration, rinsed with a small amount of hot deionized water, and the combined filtrate enters the recovery system. The filter cake is heated at 100°C for 1 hour at a material-to-water ratio of 1:5, then separated by suction filtration, and dried in an oven at 180°C. Dry for 16 hours to obtain BaCO 3 sample 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com