Alpha-TeO2 of micro structure and production method and application thereof

A microstructure, resulting technology, applied in the preparation of organic compounds, preparation of carboxylates, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

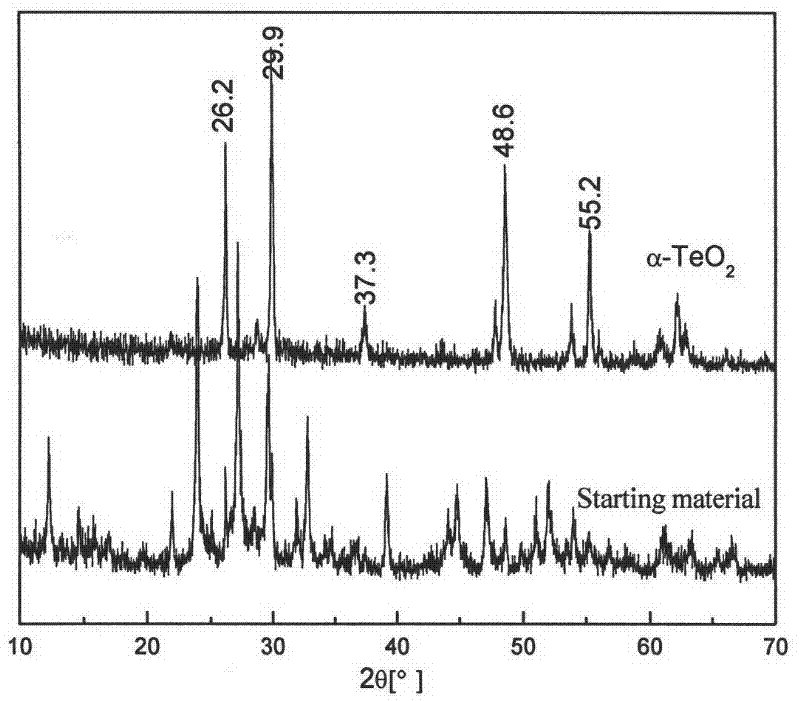

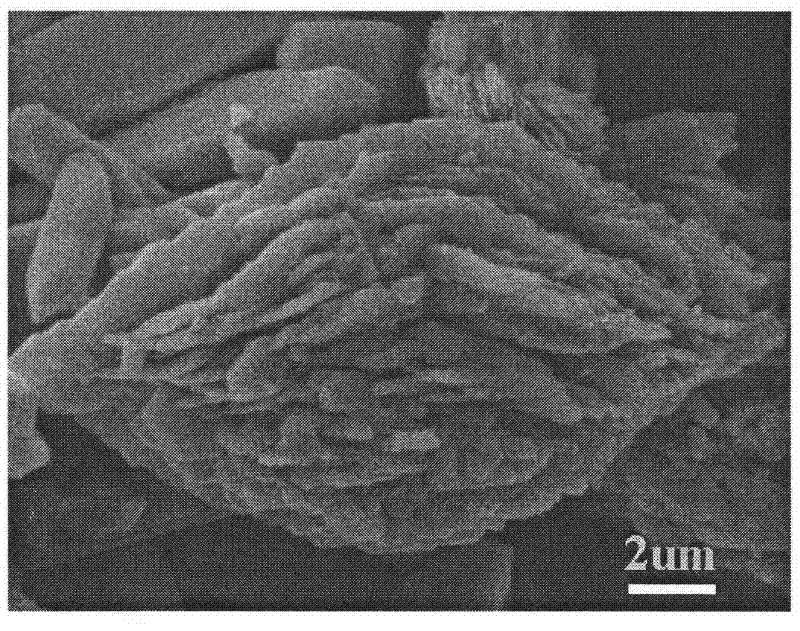

[0023] Weigh 0.5g NaOH and 1gβ-TeO 2 Mix, add 10ml distilled water, stir to form a white suspension, add 1g NH 4 NO 3 Finally, 63ml of water was added in total, and the mixture was transferred to a polytetrafluoro-lined stainless steel hydrothermal kettle with a hydrothermal temperature of 175°C and a hydrothermal time of 72h. The product was separated by centrifugation, washed with water and dried at 100°C for 12 hours. The resulting α-TeO 2 The product contains micron-scale columnar crystals, and there are also crystal clusters formed by the accumulation of submicron-scale small wafers, see the attached figure 2 .

Embodiment 2

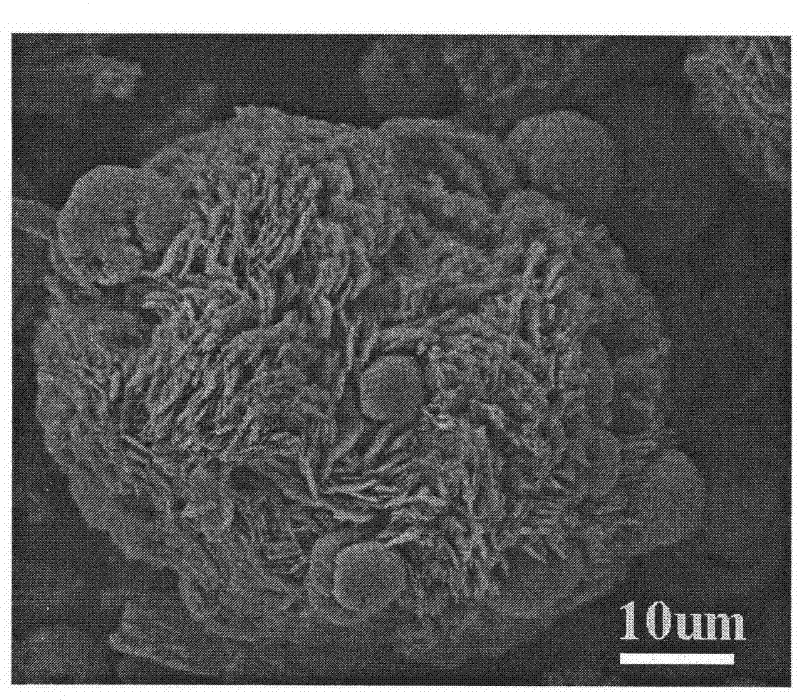

[0025] Weigh 1.0g NaOH and 1gβ-TeO 2 Mix, add 20ml distilled water, stir to form a suspension, add 1.5g NH 4 NO 3 , and finally add 105ml of water in total, and transfer the mixture to a polytetrafluoro-lined stainless steel hydrothermal kettle with a hydrothermal temperature of 175°C and a hydrothermal time of 72h. The product was separated by centrifugation, washed with water and dried at 100°C for 12 hours. The resulting α-TeO 2 The product is composed of a large number of submicron-sized dense small wafers piled up into large spherical clusters and some small spheres, see the attached image 3 .

Embodiment 3

[0027] Weigh 0.5g NaOH and 1gβ-TeO 2 Mix, add 10ml distilled water, stir to form a suspension, add 1.5g NH 4 NO 3 Finally, 75ml of water was added in total, and the mixture was transferred to a polytetrafluoro-lined stainless steel hydrothermal kettle with a hydrothermal temperature of 175°C and a hydrothermal time of 96h. The product was separated by centrifugation, washed with water and dried at 100°C for 12 hours. The resulting α-TeO 2 The product consists of many submicron-sized dense small wafers stacked into large spherical crystal clusters, occasionally with a small amount of micron-sized spheres, see the attached Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com