Processing technology and device of surface ink jet printing

A technology of inkjet printing and craftsmanship, applied in printing, typewriters, etc., can solve the problems of complexity, high production cost, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention provides a surface inkjet printing process, which uses the inkjet printing process to realize printing on complex curved surfaces by controlling the direction of movement of the printing nozzle.

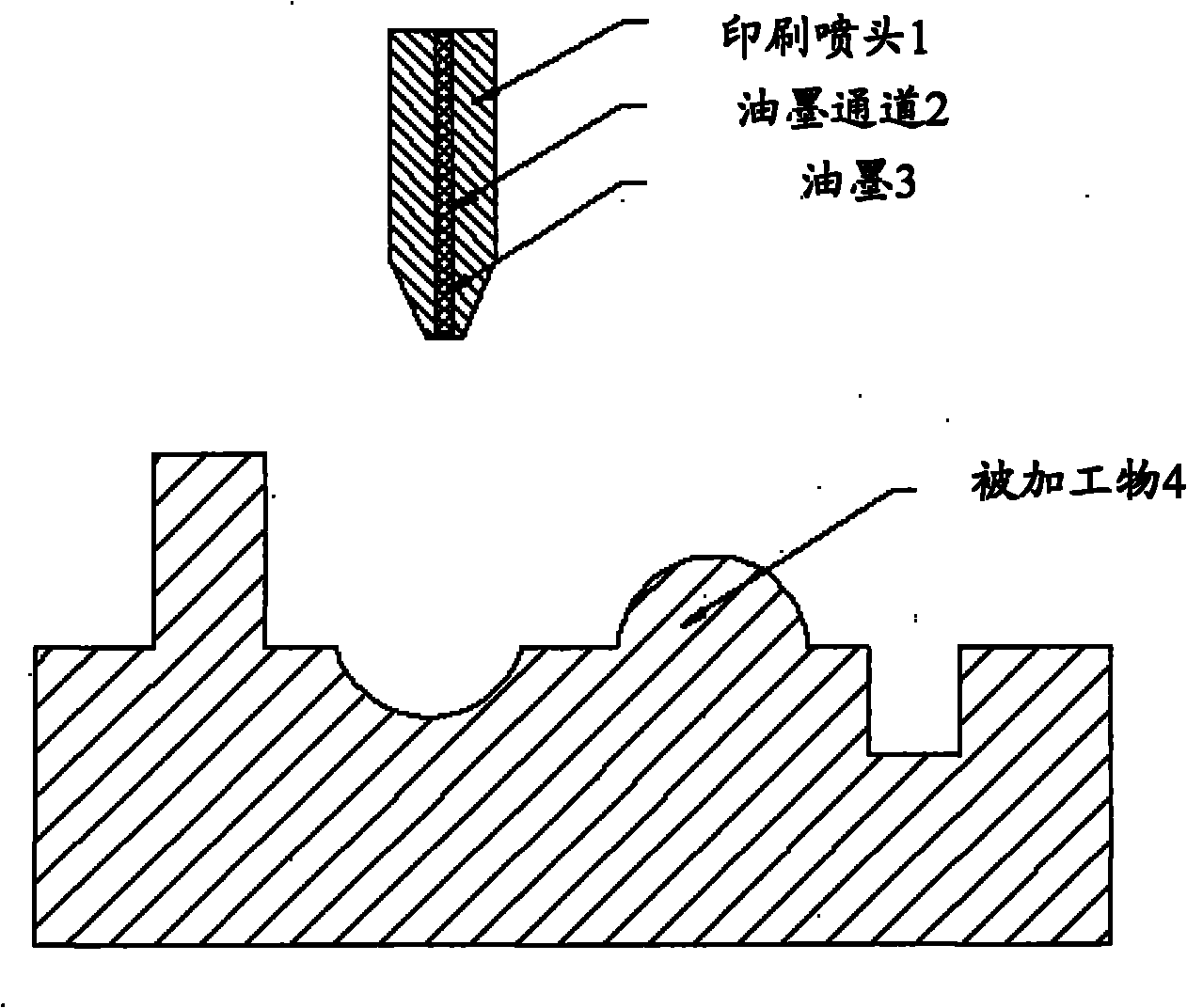

[0019] see figure 1 A system for printing complex curved surfaces using an inkjet printing process includes: a printing nozzle 1 , an ink channel 2 in the printing nozzle 1 , an ink 3 and a workpiece 4 .

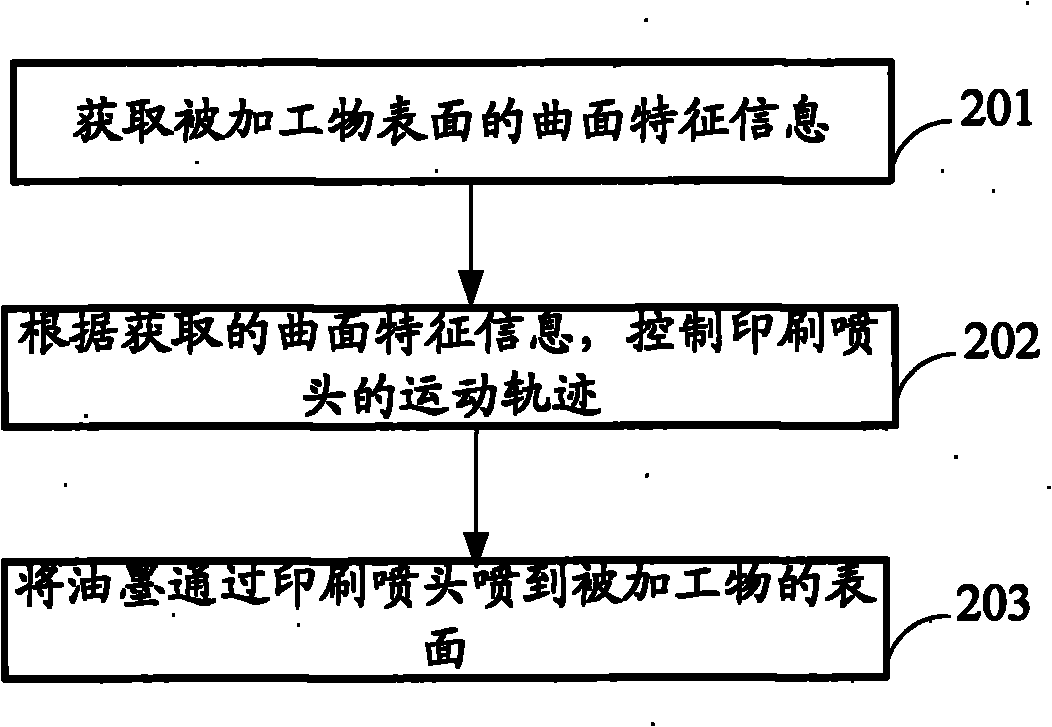

[0020] In this system, the process of surface inkjet printing treatment is described in figure 2 ,include:

[0021] Step 201: Obtain curved surface feature information on the surface of the workpiece 4 .

[0022] Here, the curved surface feature information on the surface of the workpiece 4 can be acquired by a scanner. Wherein, the curved surface feature information of the surface of the workpiece 4 includes the three-dimensional coordinate value of each electric field on the surface of the workpiece 4 .

[0023] Step 202: Control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com