Thorn wrench for preventing tooth breakup

A ratcheting and wrench technology, applied in the field of ratcheting wrenches, can solve the problems of tooth chipping, reduced production capacity, and scrapped socket wrench 6, etc., and achieve the effect of reducing tooth chipping, improving meshing stability, and overcoming the obstruction of oil pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

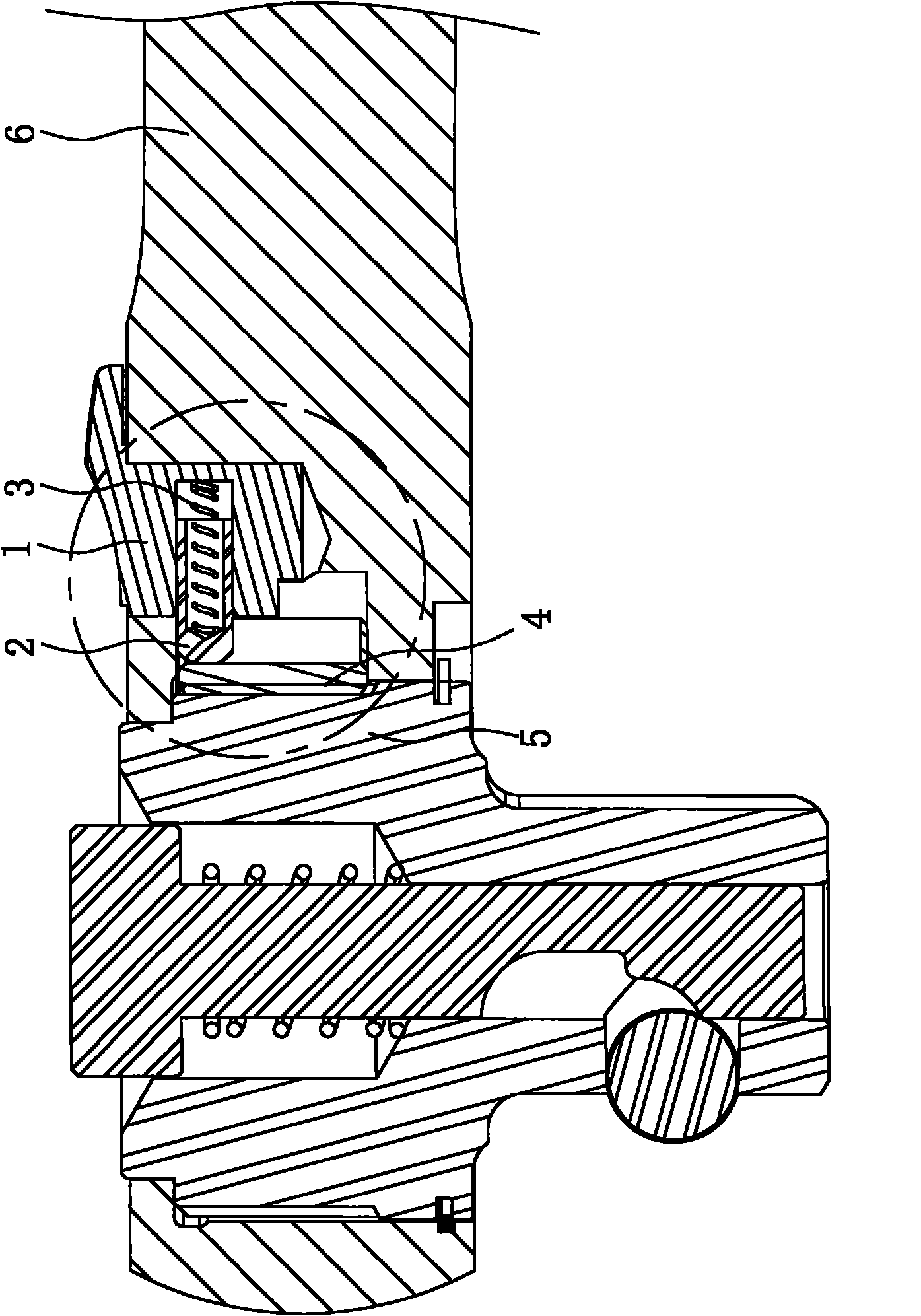

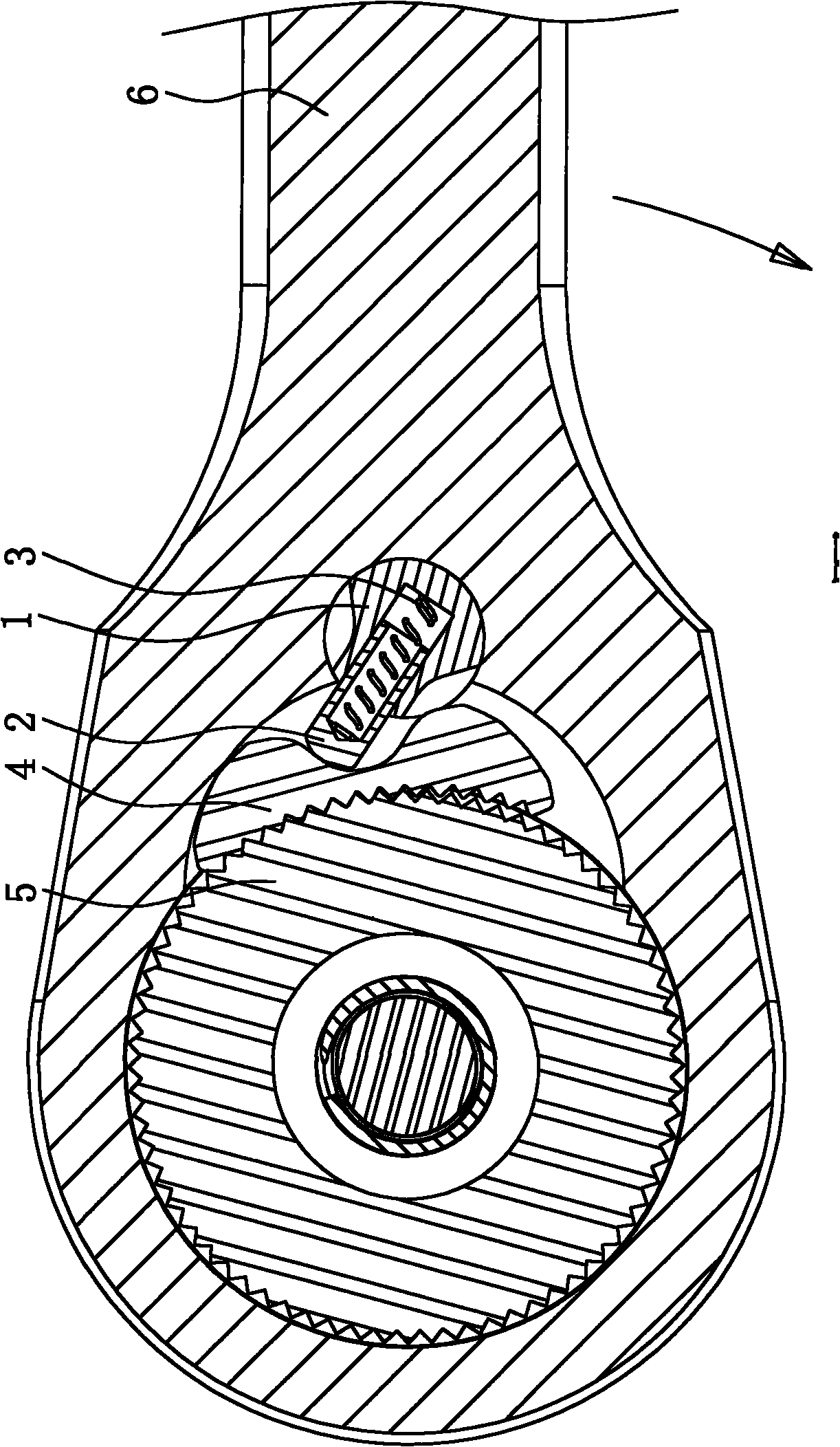

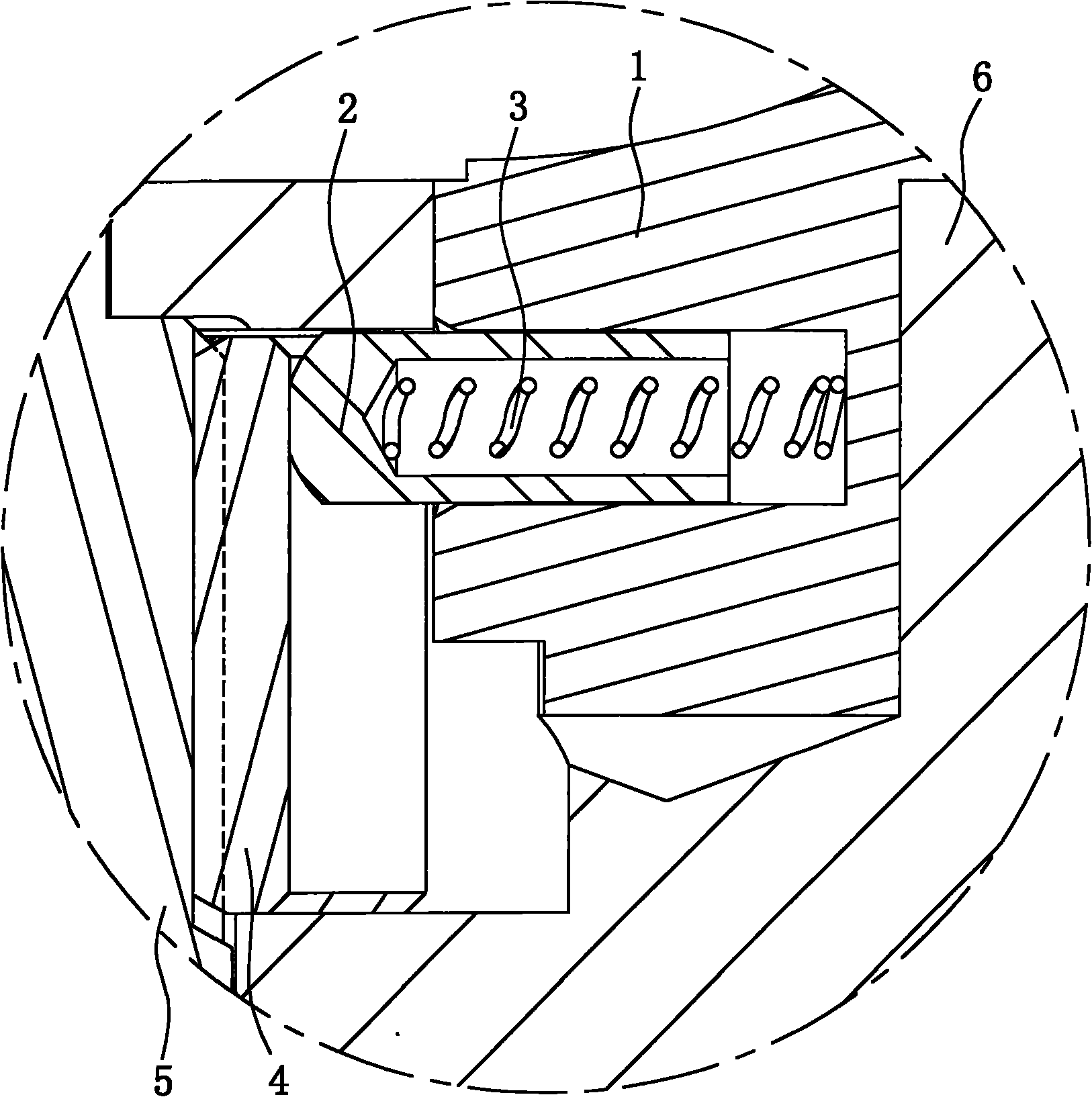

[0034] refer to Figure 7 and Figure 8 , is the first embodiment of the ratchet wrench of the present invention, which includes a body 10, a driving body 20, a ratchet member 30 and a control device 40; wherein:

[0035] The body 10 has a handle body 11, the handle body 11 is for the user to hold, the handle body 11 is in the shape of a long rod and has an axis L11 (see Figure 9 ). One end of the handle body 11 forms a head 12, the head 12 has a first side 121 and a second side 122 opposite to each other, the head 12 is provided with an accommodating hole 13 passing through the first side 121 and the second side 122, accommodating The receiving hole 13 is circular and has an axis L13 , and the axis L13 of the receiving hole 13 is perpendicular to the axis L11 of the handle body 11 . A buckle groove 131 is formed in the accommodating hole 13 adjacent to the second side 122 of the head 12 .

[0036]The head 12 is further provided with a control slot 14 adjacent to the hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com