Hydraulic transmission loop of diagonal cutter shearing machine

A technology of hydraulic transmission and shearing machine is applied in the field of steel sheet processing, which can solve the problems of increasing equipment cost and equipment volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

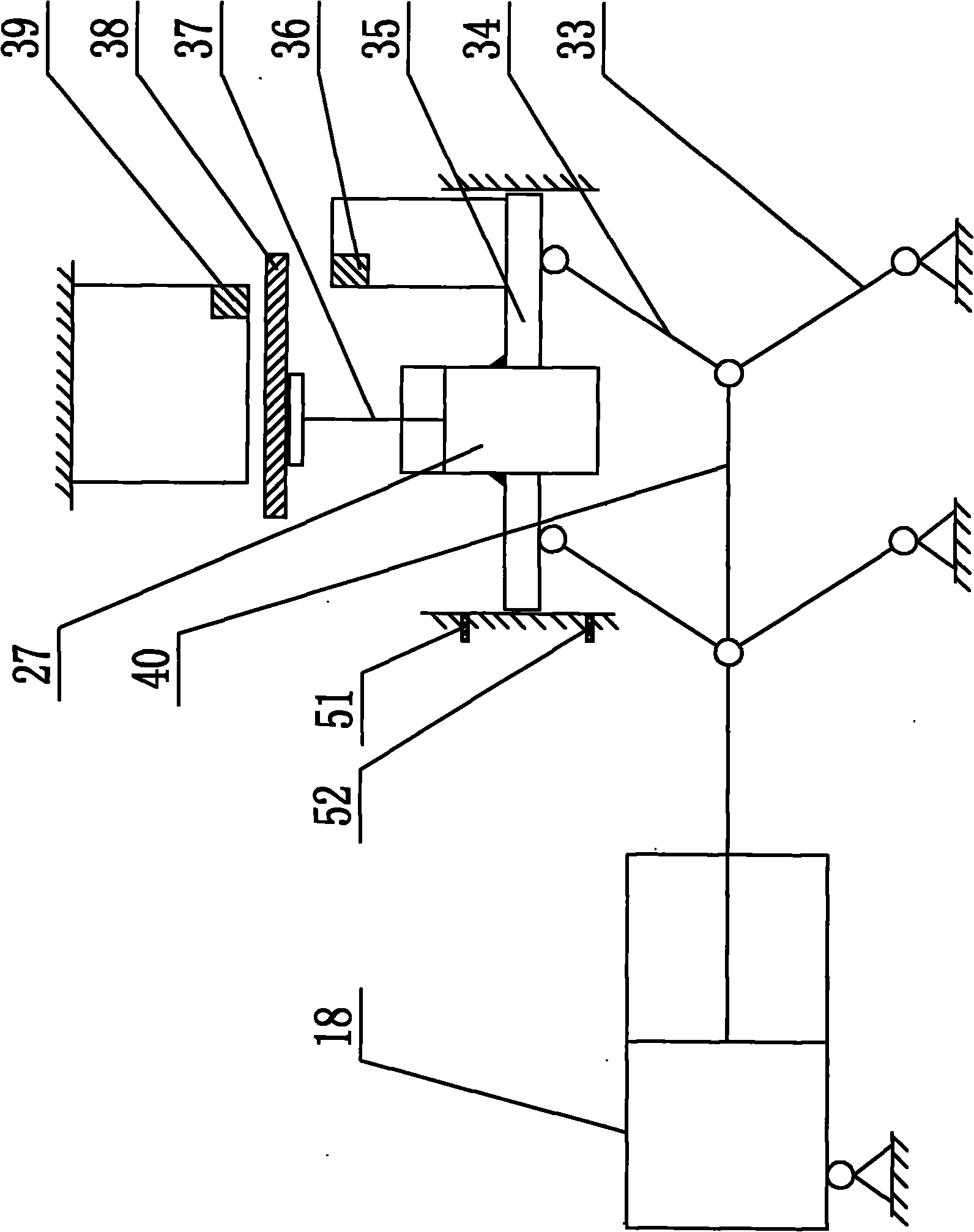

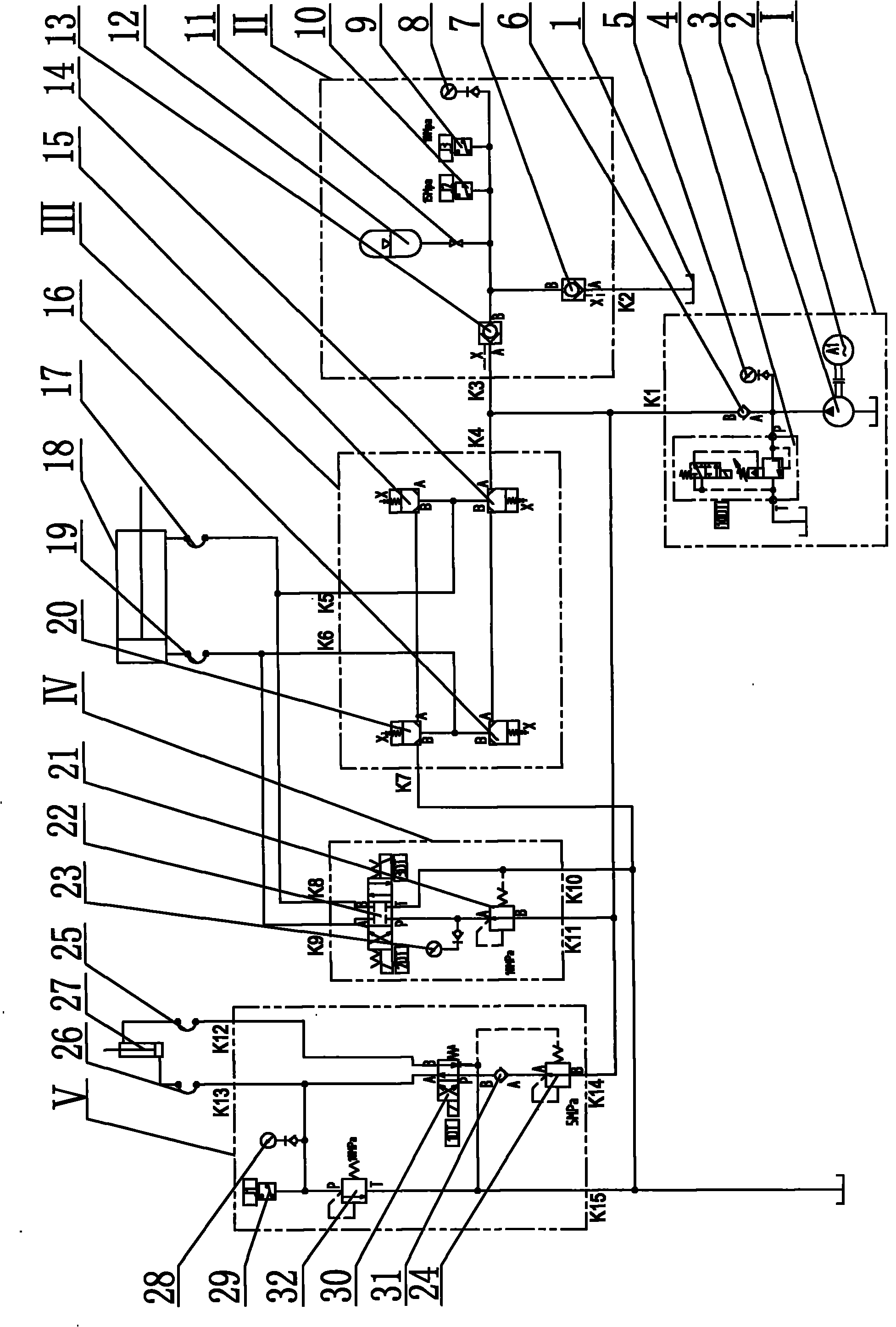

[0032] Taking the two-position four-way electromagnetic reversing valve as the pilot valve of the cartridge valve and the hydraulic control check valve as an example, its hydraulic principle is as follows: Figure 4 as shown,

[0033] A hydraulic transmission circuit for an oblique blade shearing machine, comprising a high-pressure pump source I, an accumulator control device II, a shearing cylinder control device III, a shear blade adjustment control device IV, and a platen cylinder control device V. The pressure oil port K1 of the high-pressure pump source I is respectively connected with the pressure oil port K3 of the accumulator control device II, the pressure oil port K4 of the shear cylinder control device III, the pressure oil port K11 of the shear blade adjustment control device IV and the pressure plate oil cylinder. The pressure oil port K14 of the device V is connected; the oil return port K2 of the accumulator control device II, the oil return port K7 of the shear...

Embodiment 2

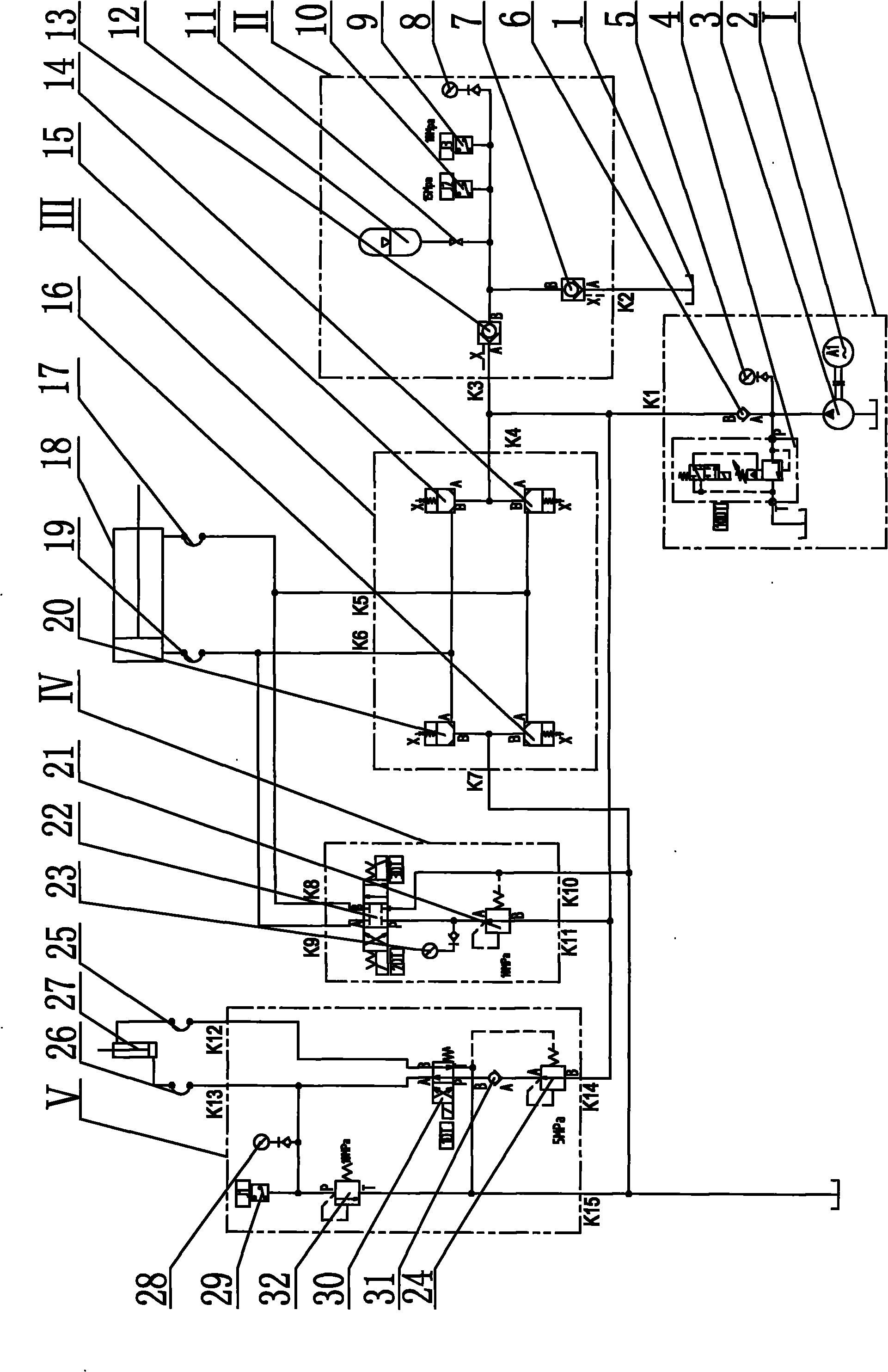

[0040] Taking the two-position four-way electromagnetic reversing valve as the pilot valve of the cartridge valve and the hydraulic control check valve as an example, its hydraulic principle is as follows: Figure 5 as shown,

[0041] The structural composition and working process of the high-pressure pump source I, the accumulator control device II, the cutting blade adjustment control device IV, and the pressure plate cylinder control device V of this embodiment are exactly the same as those of the first embodiment, and the main differences from the first embodiment are It lies in the connection mode of the shear cylinder control device III.

[0042] The connection method is: the inlet A of the fourth cartridge valve 14 is respectively connected with the working oil port K5 of the shear cylinder control device III and the inlet A of the third cartridge valve 16, and the inlet A of the first cartridge valve 20 is respectively It is connected with the working oil port K6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com