Method for preparing ZnO/attapulgite composite antibacterial agent

A compound antibacterial agent and attapulgite technology, applied in the field of inorganic non-metallic materials, can solve the problems of low antibacterial rate of pure ZnO, affect antibacterial performance, small contact area, etc., achieve low price, improve antibacterial effect, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

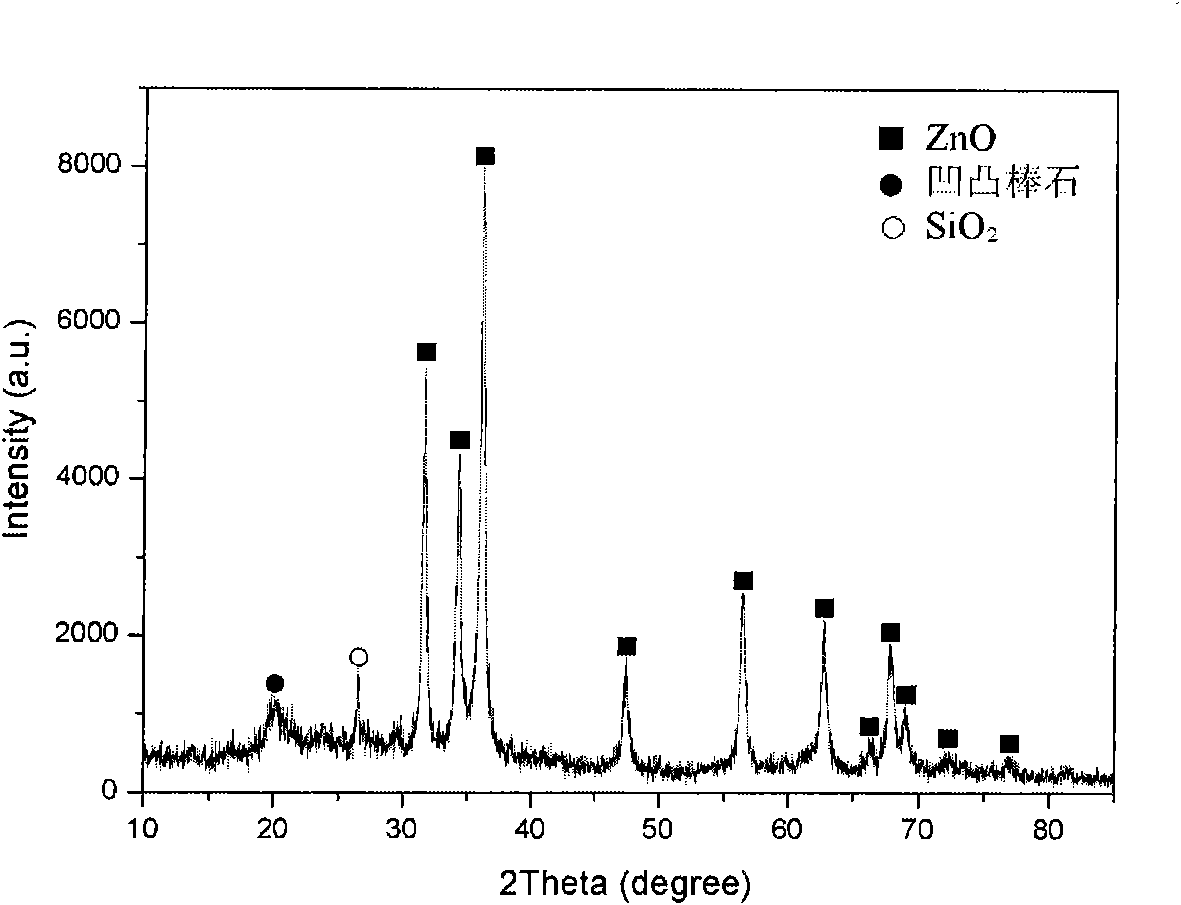

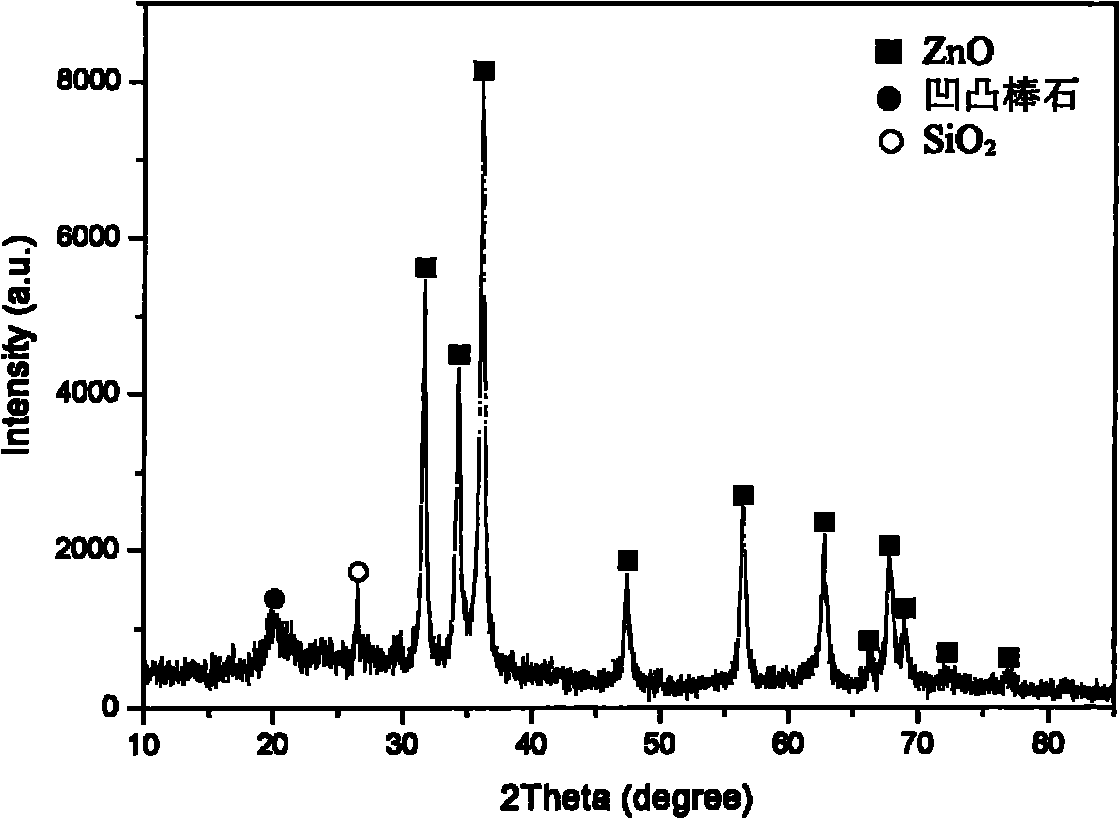

Image

Examples

Embodiment 1

[0020] 15g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 80mL of distilled water, and 7.5g of attapulgite powder with an average particle size of less than 30 microns was added to the solution, stirred, and at the same time, after ultrasonic dispersion for 15min, the stirring was continued to obtain attapulgite and Zn(NO 3 ) 2 Suspension composed; add NaOH solution containing 4g of NaOH quality to the suspension, stir until fully mixed to obtain a suspension composed of zinc hydroxide and attapulgite, and suction filter the suspension , the filter residue was dried at 80-90°C for 2.5h, calcined at 500°C for 2h, and naturally cooled to room temperature to obtain the ZnO / attapulgite composite antibacterial agent.

[0021] The powder is tested according to the following method. Weigh 10g of peptone, 5g of beef extract, and 5g of NaCl solid into a 1000mL Erlenmeyer flask, fully dissolve, adjust the pH to 7, and sterilize in a high-temperature sterilizer at 121°C for 30min to obtain LB ...

Embodiment 2

[0023] 15g ZnSO 2 Dissolve in 80mL of distilled water, add 6g of attapulgite powder with an average particle size of less than 30 microns to the solution, stir, and at the same time disperse with ultrasonic waves for 15min, continue stirring to obtain attapulgite and ZnSO 2 Suspension composed; add NaOH solution containing 3.75g of NaOH quality to the suspension, stir until fully mixed to obtain a suspension composed of zinc hydroxide and attapulgite, and pump the suspension Filter, take the filter residue, dry at 80-90°C for 2 hours, calcinate at 480°C for 3 hours, and cool naturally to room temperature to prepare the ZnO / attapulgite composite antibacterial agent.

[0024] The obtained product is detected by the detection method of Example 1, and its antibacterial performance reaches 96%.

Embodiment 3

[0026] 15g ZnCl 2 Dissolve in 80mL of distilled water, add 9g of attapulgite powder with an average particle size of less than 30 microns to the solution, stir, and at the same time disperse with ultrasonic waves for 15min, continue stirring to obtain attapulgite and ZnCl 2 Suspension composed; add NaOH solution containing 4.5g of NaOH quality to the suspension, stir until fully mixed to obtain a suspension composed of zinc hydroxide and attapulgite, and pump the suspension Filter, take the filter residue and dry at 80-90°C for 3 hours, calcined at 520°C for 1 hour, and cool naturally to room temperature to prepare the ZnO / attapulgite composite antibacterial agent.

[0027] The obtained product is detected by the detection method of Example 1, and its antibacterial performance reaches 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com