Embedded capacitance printed circuit board and production method thereof

A technology for printed circuit boards and manufacturing methods, which is applied in the manufacture of printed circuits, assembly of printed circuits with electrical components, printed circuits, etc., and can solve problems such as tearing of inner layer boards, easy slippage of inner layer boards, and lower product yields , to achieve the effect of improving strength, ensuring no slippage, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] This implementation mode is a specific implementation mode of the first technical solution of the present invention.

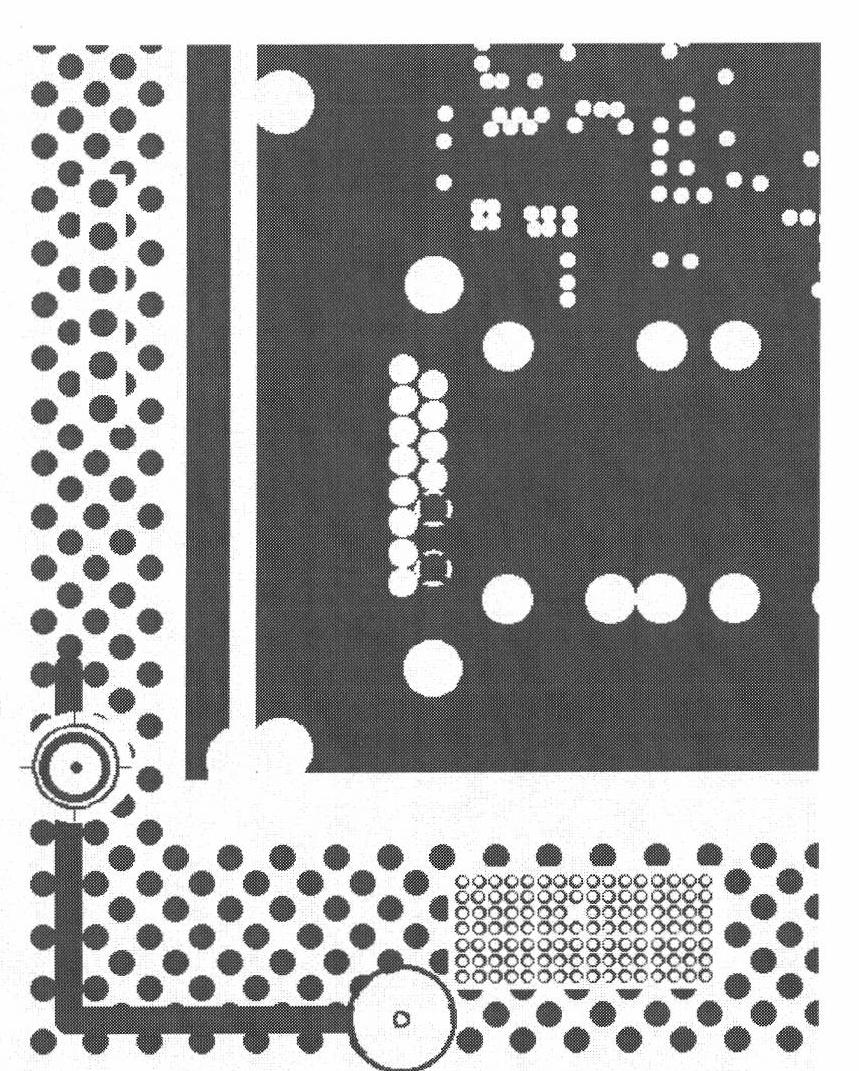

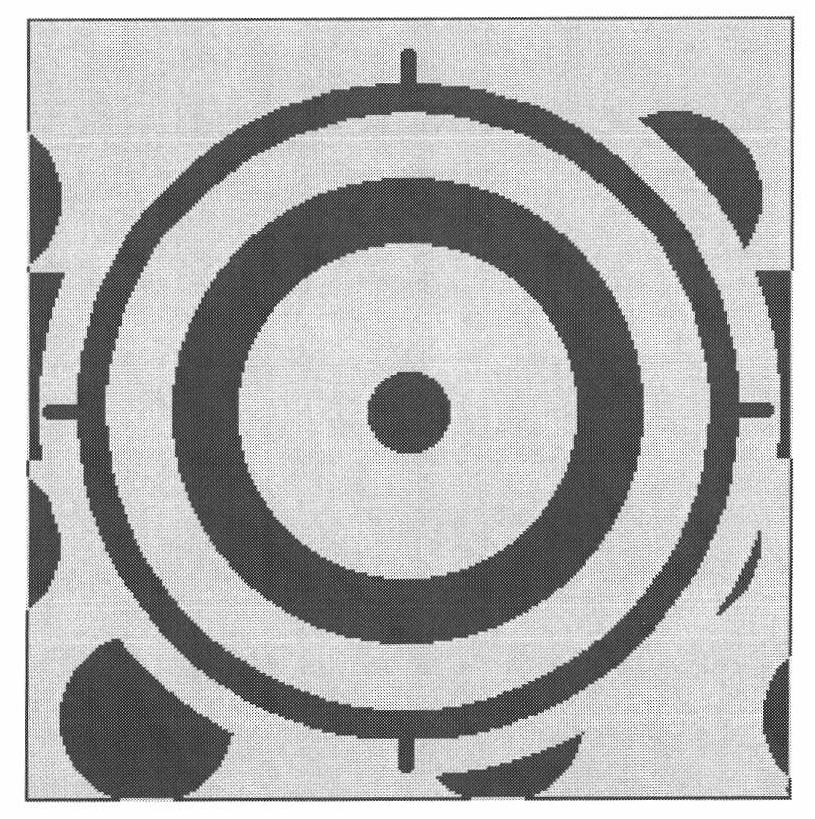

[0024] The embedded capacitor printed circuit board of this embodiment includes multilayer boards for forming capacitors, each layer of boards includes a thin film material layer and copper layers covering both sides of the thin film material layer. figure 1 It is a partial view of a layer of the existing printed circuit board, and its frame part is provided with a blocking block for blocking and controlling the flow of glue in the pressing process, such as figure 2 As shown, in the board frame of the present invention, the blocking block part is set as several evenly distributed glue flow grooves 1, and the glue flow grooves are only arranged in the copper layers on both sides of the board. . Because the design of the flow glue tank of the present invention retains most of the copper layer on the surface of the original board, the frame strength of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com