Safety lever of punch

A lever and punching technology, applied in safety equipment, engineering safety devices, metal processing equipment, etc., can solve the problems of weak electrical control, high value, high incidence of mechanical failure, etc., and achieve the effect of reliable use, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

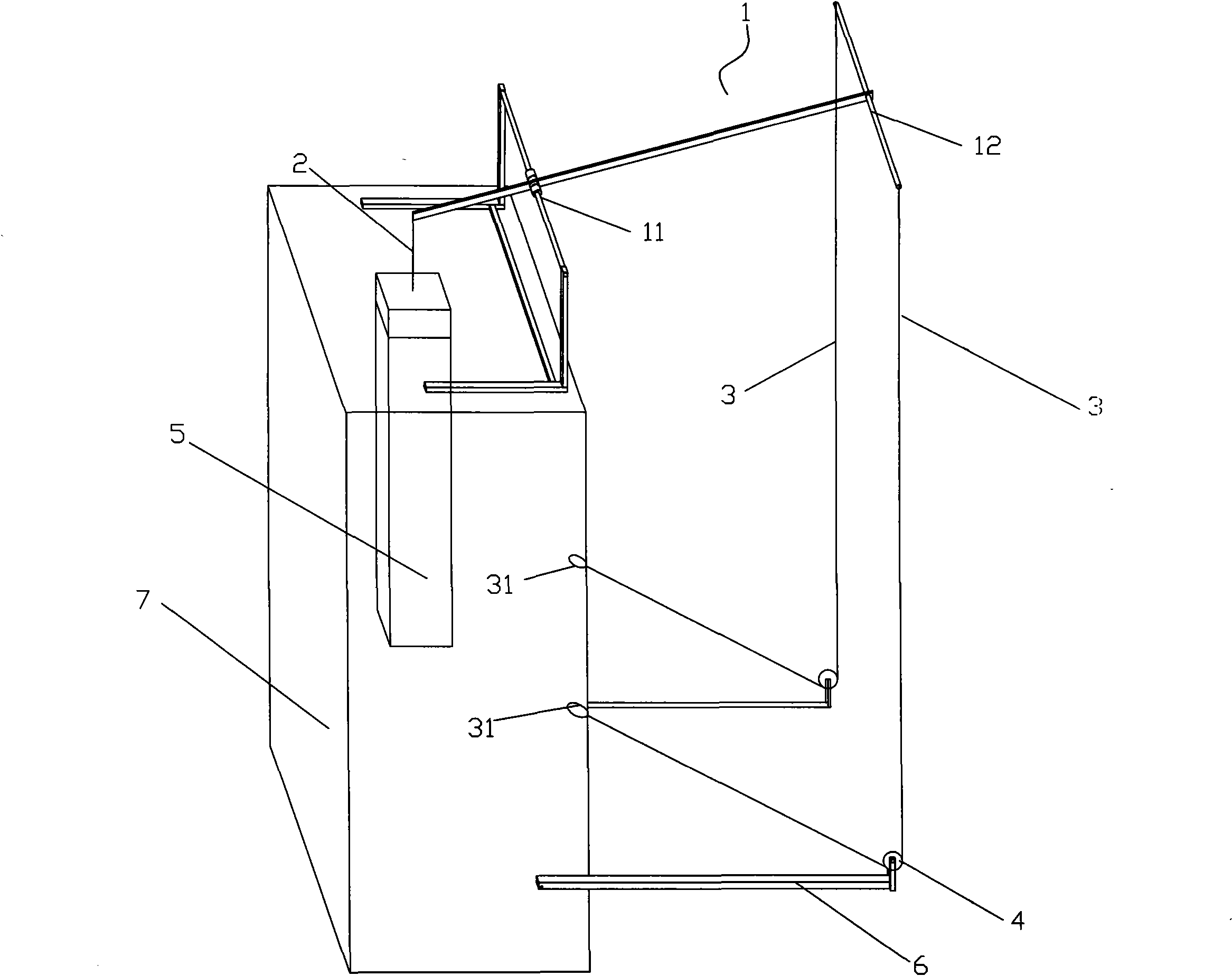

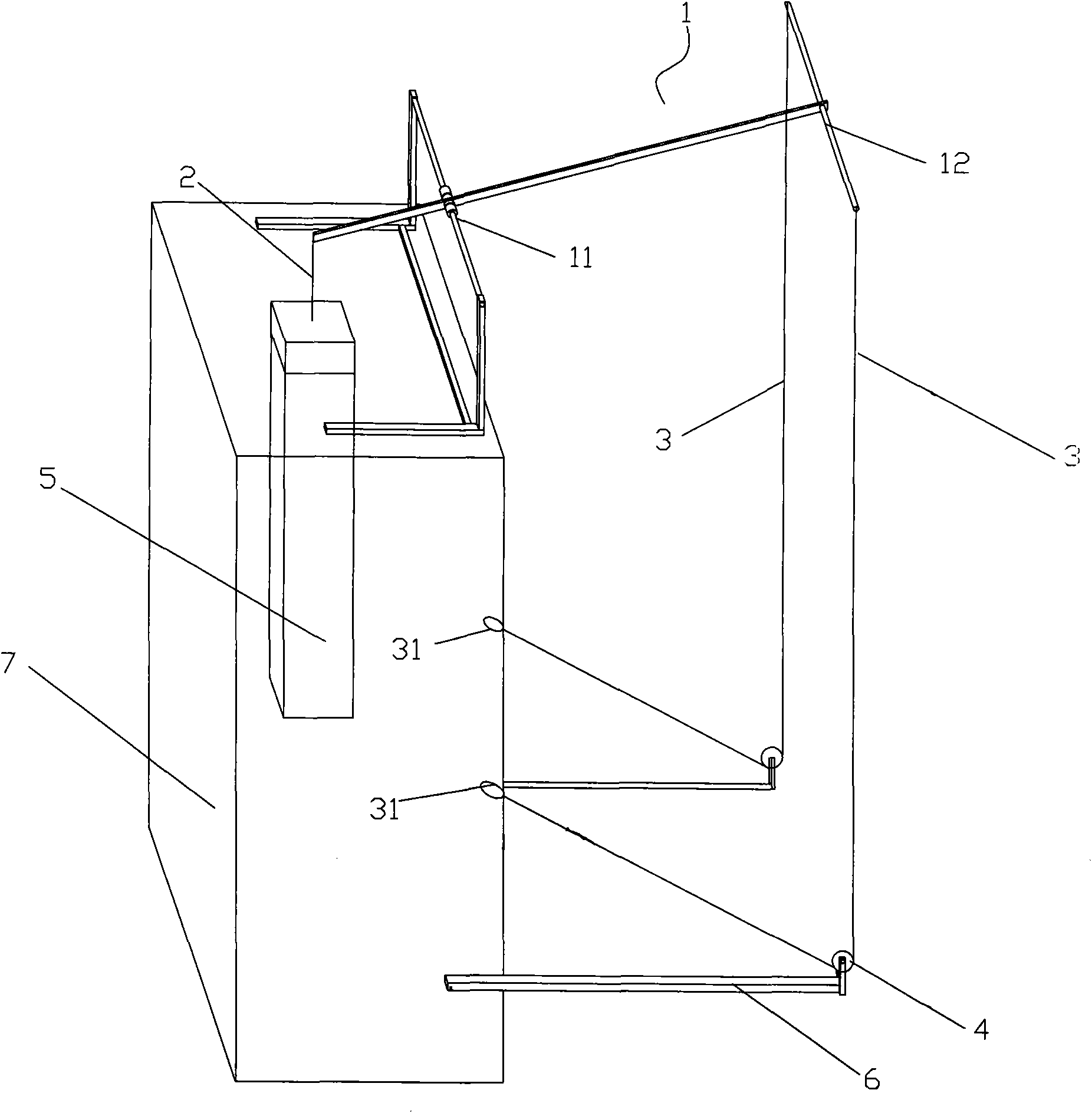

[0014] Embodiment: A safety lever for a punch press, including a lever 1, a first rope 2, a second rope 3 and a pulley 4. Based on the direction of use, the lower end of the first rope 2 is fixedly positioned on the die punch 5. The first rope 2 The upper end is fixedly connected with one end of the lever 1. The lever 1 is provided with a fulcrum 11. The lever can rotate around the fulcrum. pulley 4 and turn, the second rope 3 one end is provided with lasso 31 respectively, and lasso 31 can be placed on the working finger of the staff, and pulley 4 position is fixed, and in use, the lasso 31 sets of second rope 3 is set. On the worker's middle finger, when the punch 5 of the punch press is lifted up, the weight of the end of the lever 1 connected to the second rope 3 is greater than the weight of the end connected to the first rope 2, so that it turns clockwise around the fulcrum 11 (observed below) The direction shall prevail) to rotate, at this time, the staff's hand can mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap