A kind of multi-component composite eccentric fiber and its preparation method

An eccentric fiber and multi-component technology, applied in fiber processing, conjugated synthetic polymer artificial filament, artificial filament cleaning/drying, etc., can solve the problem of production cost reduction, poor compatibility between the skin layer and the core layer, etc. problem, to achieve the effect of cost reduction, low density and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

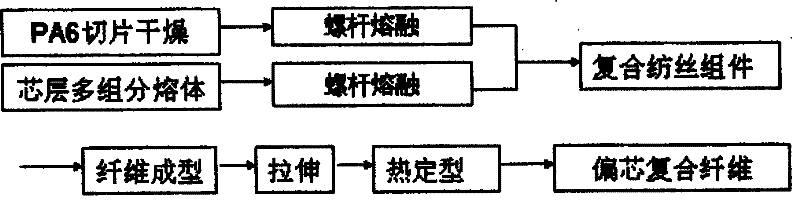

Method used

Image

Examples

Embodiment 1

[0036] The core layer component is PP and maleic anhydride modified PP, the mass ratio is 60:40, the skin layer component is PA6, and the graft ratio of maleic anhydride modified PP is 0.6%.

[0037] The composite mass ratio of skin layer / core layer is 70:30, PA6 drying process: drying temperature 110°C, drying time 8 hours, vacuum degree during drying: 0.1MPa; spinning temperature: melting temperature: Zone I: 230°C, Zone II : 250°C, zone III: 260°C, zone IV: 278°C, the temperature of the metering pump is 265°C. Core component drying process: drying temperature 110°C, drying time 8 hours, vacuum degree 0.1MPa during drying; spinning temperature: melting temperature: zone I: 210°C, zone II: 230°C, zone III: 250°C, zone IV Zone: 270°C, composite spin pack temperature 265°C. The spinning speed is 3300m / min, the stretching temperature of the stretching process is 100°C, and the stretching ratio is 1.5 times to obtain a composite three-dimensional crimped fiber of various compone...

Embodiment 2

[0039] The core component melt is PP and EVA, the mass ratio is 90:10, and the skin component is PA6.

[0040] The composite mass ratio of skin layer / core layer is 70:30, PA6 drying process: drying temperature 110°C, drying time 8 hours, vacuum degree during drying: 0.1MPa; spinning temperature: melting temperature: Zone I: 230°C, zone II : 250°C, zone III: 260°C, zone IV: 278°C, the temperature of the metering pump is 265°C. Core component drying process: drying temperature 110°C, drying time 8 hours, vacuum degree 0.1MPa during drying; spinning temperature: melting temperature: zone I: 210°C, zone II: 230°C, zone III: 250°C, zone IV Zone: 270°C, composite spin pack temperature 265°C. The spinning speed is 3000m / min, the stretching temperature of the stretching process is 100°C, and the stretching ratio is 1.65 times to obtain a composite three-dimensional crimped fiber of multiple components whose cross-sectional area of the skin layer component accounts for 70% of the cr...

Embodiment 3

[0042] The core layer component is PP and maleic anhydride modified PP, the mass ratio is 80:20, the skin layer component is PA6, and the graft ratio of maleic anhydride modified PP is 5%.

[0043] The composite mass ratio of skin layer / core layer is 50:50, PA6 drying process: drying temperature 110°C, drying time 8 hours, vacuum degree during drying: 0.1MPa; spinning temperature: melting temperature: Zone I: 230°C, Zone II : 250°C, zone III: 260°C, zone IV: 278°C, the temperature of the metering pump is 265°C. Core layer component drying process: drying temperature 110°C, drying time 8 hours, vacuum degree 0.1MPa during drying; spinning temperature: melting temperature: zone I: 210°C, zone II: 230°C, zone III: 250°C, Zone IV: 270°C, the temperature of the composite spin pack is 265°C. The spinning speed is 1500m / min, the stretching temperature of the stretching process is 100°C, and the stretching ratio is 2.8 times to obtain a composite three-dimensional crimped fiber of va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com